Cement raw material powder distributor even in material distribution

A technology of cement raw materials and distributors, which is applied to preheating costs, furnaces, lighting and heating equipment, etc., can solve the problems of increasing coal consumption, reducing production efficiency, and decomposition due to insufficient heating, so as to improve heat exchange efficiency and reduce power consumption , increase the effect of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

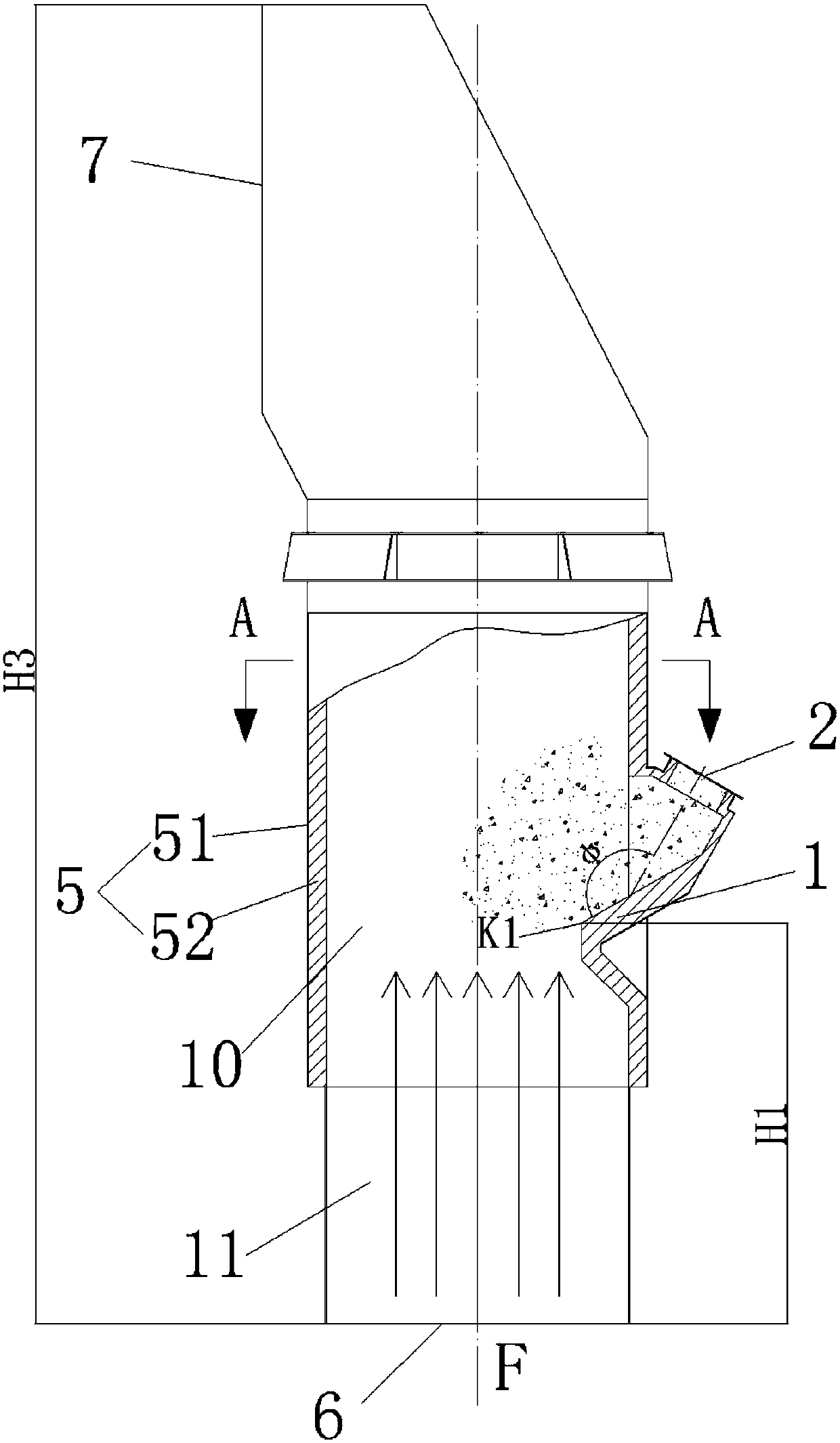

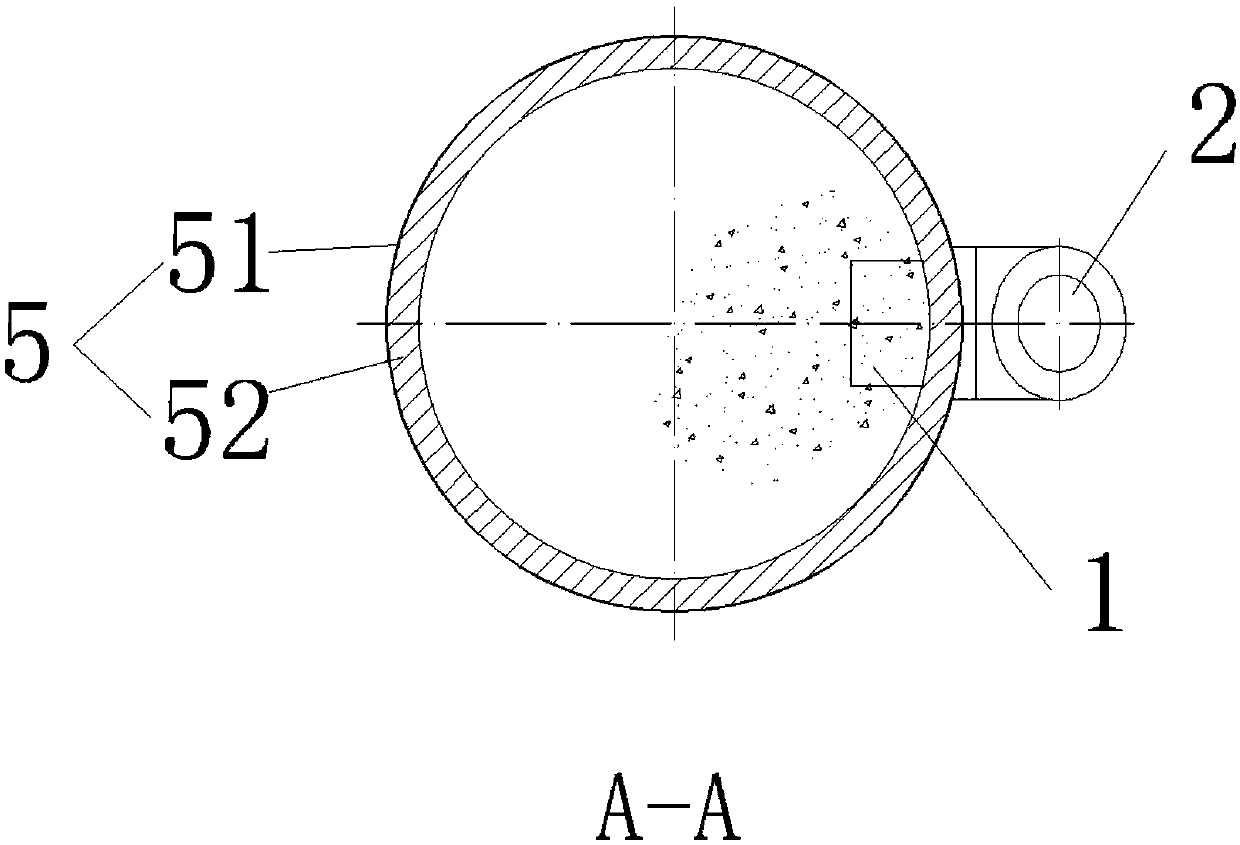

[0044] Such as Figure 5-6 The shown cement raw meal powder distributor with uniform distribution is one of the embodiments of the present invention, and it is mainly composed of a material spreading pipe and a material spreading part 1, wherein the material spreading part 1 selects the included angle β between the inclined surface and the bottom surface as 45° spreading cone; the spreading pipe is composed of connecting pipe 3, the upper port of the connecting pipe 3 coincides with the feed inlet 2 of the ascending wind pipe cavity 10 of the preheater cyclone, and is fixed by welding at the overlapping place, and connected The pipe 3 forms an included angle α of 45° between its center line and the center line of the preheater cyclone ascending air pipe cavity 10, and penetrates obliquely downward from the upper port into the preheater cyclone provided with the heat-insulating refractory shell 5 In the ascending air duct cavity 10, and extend to the middle of the duct cavity, ...

Embodiment 2

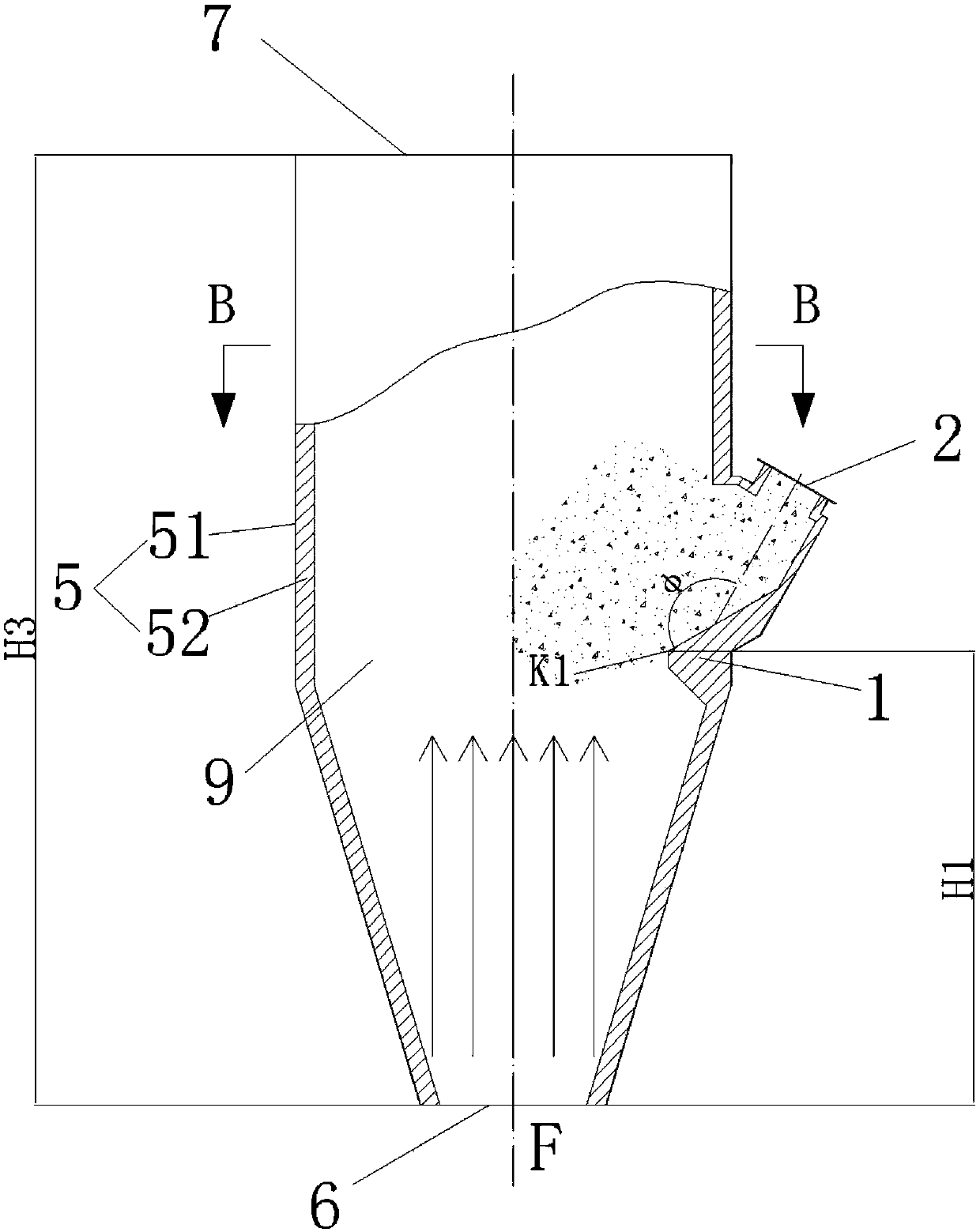

[0049] Such as Figure 7-8 , the shown uniform cement raw meal powder distributor is the second embodiment of the present invention, the distributor in this embodiment is installed on the decomposition chamber 9 in the calciner, and it is mainly composed of a spreading pipe and a spreading The material part 1 is composed of material part 1, wherein the material spreading part 1 is a material spreading cone with an angle β between the inclined surface and the bottom surface of 30°; The center line of the internal decomposition chamber 9 forms an included angle α of 30°, obliquely penetrates downwards from the upper port into the decomposition chamber in the decomposition furnace provided with the heat-insulating refractory shell 5, and extends to the middle of the chamber. The spreading plate on the original distributor is used as a bracket 8 to support the connecting pipe 3; in order to send the raw material to the set depth, the lower end of the connecting pipe 3 is also prov...

Embodiment 3

[0051] Such as Figure 9-10 , the cement raw meal powder distributor with uniform distribution is the third embodiment of the present invention. The difference between the third embodiment and the first embodiment is that the distributor in this embodiment is directly applied to the newly built Heater cyclone ascending air pipe cavity 10; wherein the spreader 1 is a spreader cone with an angle β between the inclined surface and the bottom surface of 60°, the spreader is composed of a connecting pipe 3 and a tailpipe 4, and the connecting pipe 3 is connected The center line forms an angle α with the center line of the preheater cyclone ascending air pipe chamber 10, which is 60°, and penetrates obliquely downward into the preheater cyclone ascending air pipe chamber 10 provided with a heat-insulating refractory shell 5, And extend to the middle of the pipe, the intersection of the connecting pipe 3 and the casing 5 of the ascending air duct of the preheater cyclone is fixed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com