Graphene-metal organic framework composite material, and preparation method and application thereof

A technology of metal-organic frameworks and composite materials, which is applied in the field of graphene-metal-organic framework composites and their preparation, can solve the problem of reducing the stability and recycling performance of composite materials, difficult to control the structure of composite materials, and limiting the conductivity of graphene and other problems, to achieve the effect of improving the conductivity, improving the capacitance performance, and improving the uniformity of properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

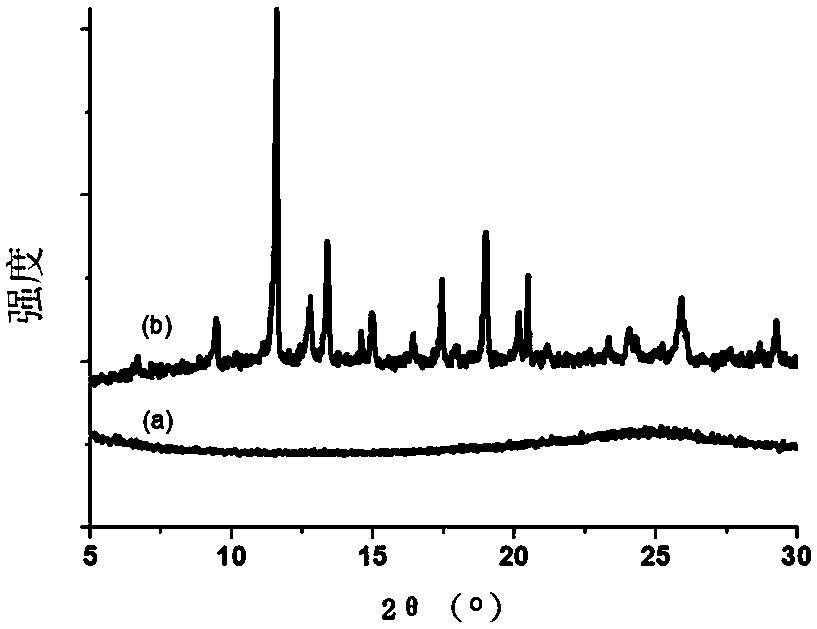

[0047] A graphene-metal organic framework composite material, including three-dimensional porous graphene and a metal organic framework compound Cu-BTC, Cu-BTC uniformly grows in the internal channel structure of the three-dimensional porous graphene.

[0048] In this embodiment, the mass ratio of Cu-BTC to three-dimensional porous graphene is 12:1.

[0049] In this embodiment, the graphene-metal organic framework composite material is a bulk structure.

[0050] A kind of preparation method of the graphene-metal organic framework composite material of above-mentioned present embodiment, comprises the following steps:

[0051] (1) Preparation of three-dimensional porous graphene: Take 100 mg of graphene oxide solid and put it into 20 mL of pure water, and ultrasonically disperse to obtain a uniform dispersion; transfer the dispersion into a 50 mL reactor, and react at 180 ° C for 18 h, that is The three-dimensional porous graphene hydrogel is obtained, and the graphene hydroge...

Embodiment 2

[0064] A graphene-metal organic framework composite material, including three-dimensional porous graphene and a metal organic framework compound Cu-BTC, Cu-BTC uniformly grows in the internal channel structure of the three-dimensional porous graphene.

[0065] In this embodiment, the mass ratio of Cu-BTC to three-dimensional porous graphene is 14:1.

[0066] In this embodiment, the graphene-metal organic framework composite material is a bulk structure.

[0067] A kind of preparation method of the graphene-metal organic framework composite material of above-mentioned present embodiment, comprises the following steps:

[0068] (1) Preparation of three-dimensional porous graphene: put 40 mg of graphene oxide solid prepared in Example 1 into 20 mL of pure water, and ultrasonically disperse to obtain a uniform dispersion; After reacting at high temperature for 18 hours, a three-dimensional porous graphene hydrogel is obtained, and the graphene hydrogel is freeze-dried to obtain a...

Embodiment 3

[0073] A graphene-metal organic framework composite material, including three-dimensional porous graphene and a metal organic framework compound Cu-BTC, Cu-BTC uniformly grows in the internal channel structure of the three-dimensional porous graphene.

[0074] In this embodiment, the mass ratio of Cu-BTC to three-dimensional porous graphene is 10:1.

[0075] In this embodiment, the graphene-metal organic framework composite material is a bulk structure.

[0076] A kind of preparation method of the graphene-metal organic framework composite material of above-mentioned present embodiment, comprises the following steps:

[0077] (1) Preparation of three-dimensional porous graphene: put 200 mg of graphene oxide solid prepared in Example 1 into 20 mL of pure water, and ultrasonically disperse to obtain a uniform dispersion; After reacting at high temperature for 18 hours, a three-dimensional porous graphene hydrogel is obtained, and the graphene hydrogel is freeze-dried to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass specific capacitance | aaaaa | aaaaa |

| Area specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com