Method for processing Paichongding nano-microemulsion pesticide

A technology of nano-emulsion and processing method, applied in the fields of botanical equipment and methods, pesticides, animal repellants, etc., can solve the damage of ecosystem structure and function, the coarse dispersion of drug-carrying particles, biological and human health Threats and other issues to reduce shedding, increase adhesion and coverage, and improve bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

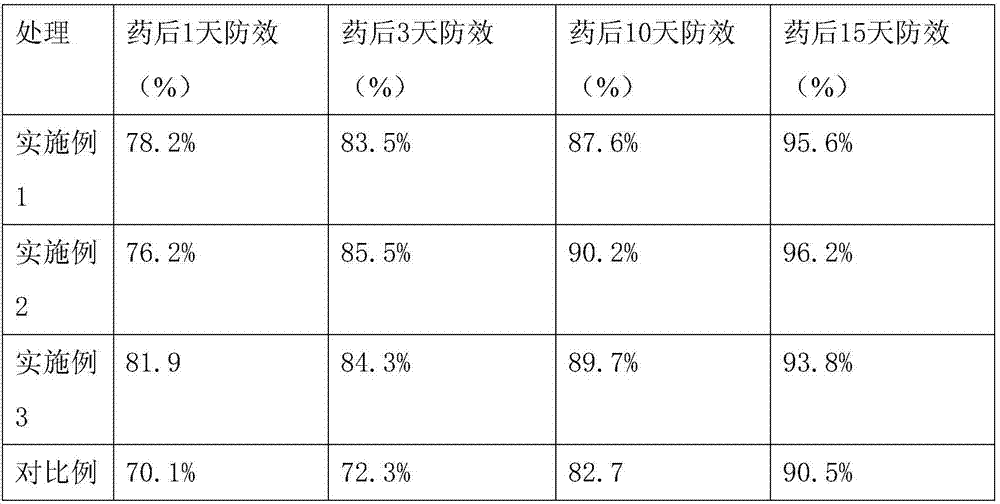

Examples

Embodiment 1

[0020] Embodiment 1 A kind of processing method of piperidin nano-microemulsion pesticide

[0021] 1) Mix Pichamid and zeolite powder at a mass ratio of 5:1 and place them in a ball mill. Metal balls with different diameters from 0.5 to 15 mm are used as grinding balls in random proportions. After ball milling for 24-48 hours, it is formed to 95 More than % of the mixture with a particle size of less than 100nm; wherein, the mass ratio of ball to material is 80:1, and the speed of the ball mill is 450 rpm;

[0022] 2) Homogenize the mixture obtained in step 1) to form an insecticidal composition, wherein the homogenization pressure is 1200 bar, and the number of homogenization times is 6;

[0023] 3) Take the surfactant fatty alcohol polyoxyethylene ether, co-surfactant glycerin, oil phase garlic oil and water to form a microemulsion, slowly drip the insecticidal composition at a rate of 1 drop / 0.5-1 minute Add it into the microemulsion, stir it while adding at a speed of 300...

Embodiment 2

[0024] Embodiment 2 A kind of processing method of piperidamid nano microemulsion pesticide

[0025] 1) Mix Pichamid and zeolite powder at a mass ratio of 10:1 and place them in a ball mill. Metal balls with different diameters from 0.5 to 15 mm are used in random proportions and used as grinding balls. After ball milling for 24-48 hours, it is formed to 95 More than % of the mixture with a particle size of less than 100nm; wherein, the mass ratio of ball to material is 100:1, and the speed of the ball mill is 500 rpm;

[0026] 2) Homogenize the mixture obtained in step 1) to form an insecticidal composition, wherein the homogenization pressure is 15000 bar, and the number of homogenization times is 6;

[0027] 2) Take the surfactant fatty alcohol polyoxyethylene ether, the co-surfactant n-butanol, the oil phase garlic oil and water to form a microemulsion, and slowly drop the insecticidal composition at a rate of 1 drop / 0.5-1 minute Add it into the microemulsion, stir it whi...

Embodiment 3

[0029] 1) Mix Pichamid and zeolite powder at a mass ratio of 8:1 and place them in a ball mill. Metal balls with different diameters ranging from 0.5 to 15 mm are used as grinding balls in random proportions. After ball milling for 24-48 hours, they are formed to 95 More than % of the mixture with a particle size of less than 100nm; wherein, the mass ratio of ball to material is 100:1, and the speed of the ball mill is 500 rpm;

[0030] 2) Homogenize the mixture obtained in step 1) to form an insecticidal composition, wherein the homogenization pressure is 13000 bar, and the number of homogenization times is 6;

[0031] 2) Mix surfactant sorbitol polyoxyethyl ether, co-surfactant n-butanol, oil phase garlic oil and water to form a microemulsion, and slowly add the insecticidal composition dropwise at a rate of 1 drop / 0.5-1 minute In the microemulsion, stir while adding at a rotating speed of 5000 rev / min, dropwise, emulsify in the emulsifying homogenizer for 60-120 minutes, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com