Preparation method of super-hydrophobic/super-oleophylic stainless steel mesh

A stainless steel mesh and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve the problems of high processing equipment requirements, unfavorable large-scale production, complicated operation process, etc., and achieve good hydrophobic effect , The preparation method is simple and convenient, and the effect of stable separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

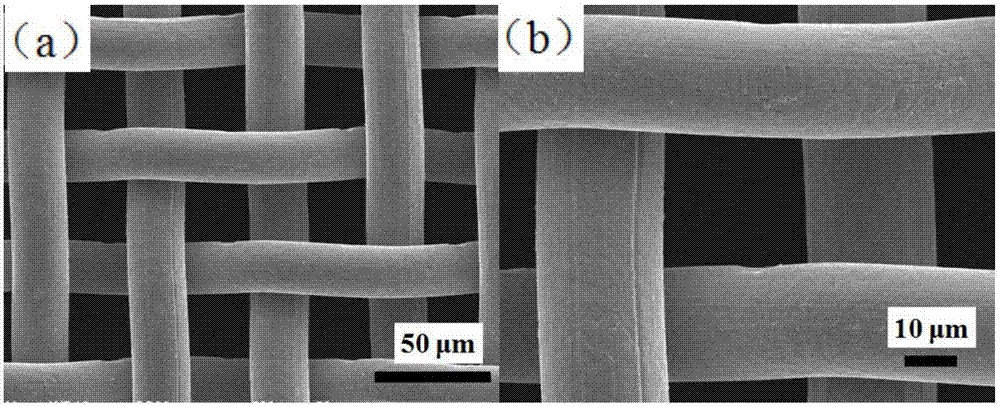

[0026] (1) Dip the 200-mesh stainless steel mesh into deionized water and ultrasonically clean it for 10 minutes, then dry it;

[0027] (2) Immerse the cleaned stainless steel mesh in 1 M hydrochloric acid and corrode it for 10 minutes, take it out, clean it ultrasonically with deionized water for 10 minutes, and then dry it;

[0028] (3) Immerse the dried stainless steel mesh in 0.1 M silver nitrate solution for 1 min, take it out, clean it ultrasonically with deionized water for 10 min, and then dry it;

[0029] (4) Finally, immerse the dried stainless steel mesh in 0.1 M stearic acid for 10 minutes, take it out and ultrasonically clean it with deionized water for 10 minutes, and then dry it to obtain an oil-water separation mesh with superhydrophobic and superlipophilic functions .

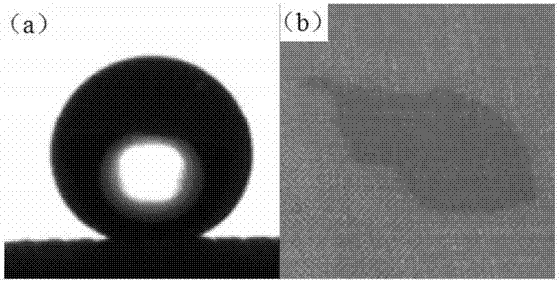

[0030] The contact angle of the stainless steel mesh with water is 140°, and the contact angle with kerosene is 0. It can realize fast and efficient separation of oil-water mixture, with good ...

Embodiment 2

[0032] (1) Soak the 300-mesh stainless steel mesh in deionized water and ultrasonically clean it for 10 minutes, then dry it;

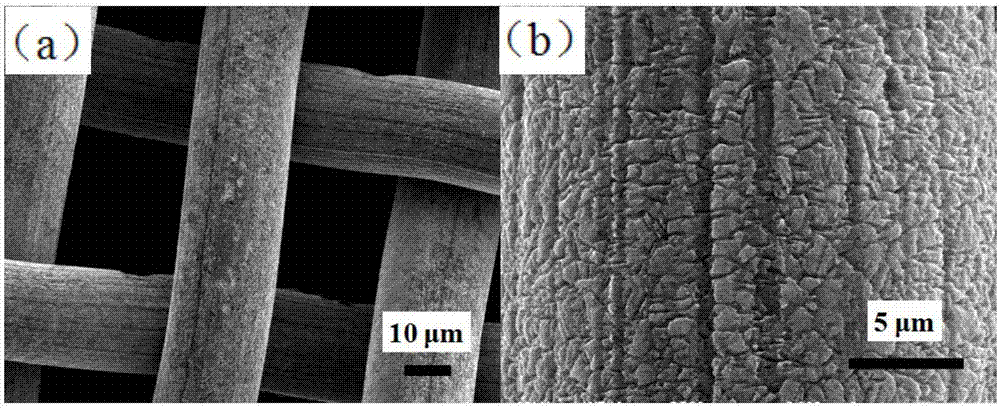

[0033] (2) Immerse the cleaned stainless steel mesh in 5 M sulfuric acid and corrode it for 60 minutes, take it out and ultrasonically clean it with deionized water for 10 minutes and then dry it;

[0034] (3) Immerse the dried stainless steel mesh in 1 M copper sulfate solution for 10 minutes, take it out, clean it ultrasonically with deionized water for 10 minutes, and then dry it;

[0035] (4) Finally, immerse the dried stainless steel mesh in 1 M palmitic acid for 60 minutes, take it out and ultrasonically clean it with deionized water for 10 minutes, and then dry it to obtain an oil-water separation mesh with superhydrophobic and superlipophilic functions.

[0036] The contact angle of the stainless steel mesh with water is 148°, and the contact angle with kerosene is 0. It can realize fast and efficient separation of oil-water mixture, with good...

Embodiment 3

[0038] (1) Immerse the 400-mesh stainless steel mesh in deionized water, ultrasonically clean it for 10 minutes, and then dry it;

[0039] (2) Immerse the cleaned stainless steel mesh in 3 M sulfuric acid and corrode it for 30 minutes, take it out and ultrasonically clean it with deionized water for 10 minutes and then dry it;

[0040] (3) Immerse the dried stainless steel mesh in 0.5 M chloroauric acid solution for 5 minutes, take it out, clean it ultrasonically with deionized water for 10 minutes, and then dry it;

[0041] (4) Finally, immerse the dried stainless steel mesh in 0.5 M hexadecanic acid to react for 30 minutes, take it out, clean it ultrasonically with deionized water for 10 minutes, and then dry it to obtain an oil-water separation mesh with superhydrophobic and superlipophilic functions membrane.

[0042] The contact angle of the stainless steel mesh with water is 145°, and the contact angle with kerosene is 0. It can realize fast and efficient separation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com