Oil-water separation device and preparation method thereof

A technology for oil-water separation and oil spillage, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high equipment cost, incomplete separation, and only removal, etc., and achieve simple preparation method and good hydrophobic effect , the effect of short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

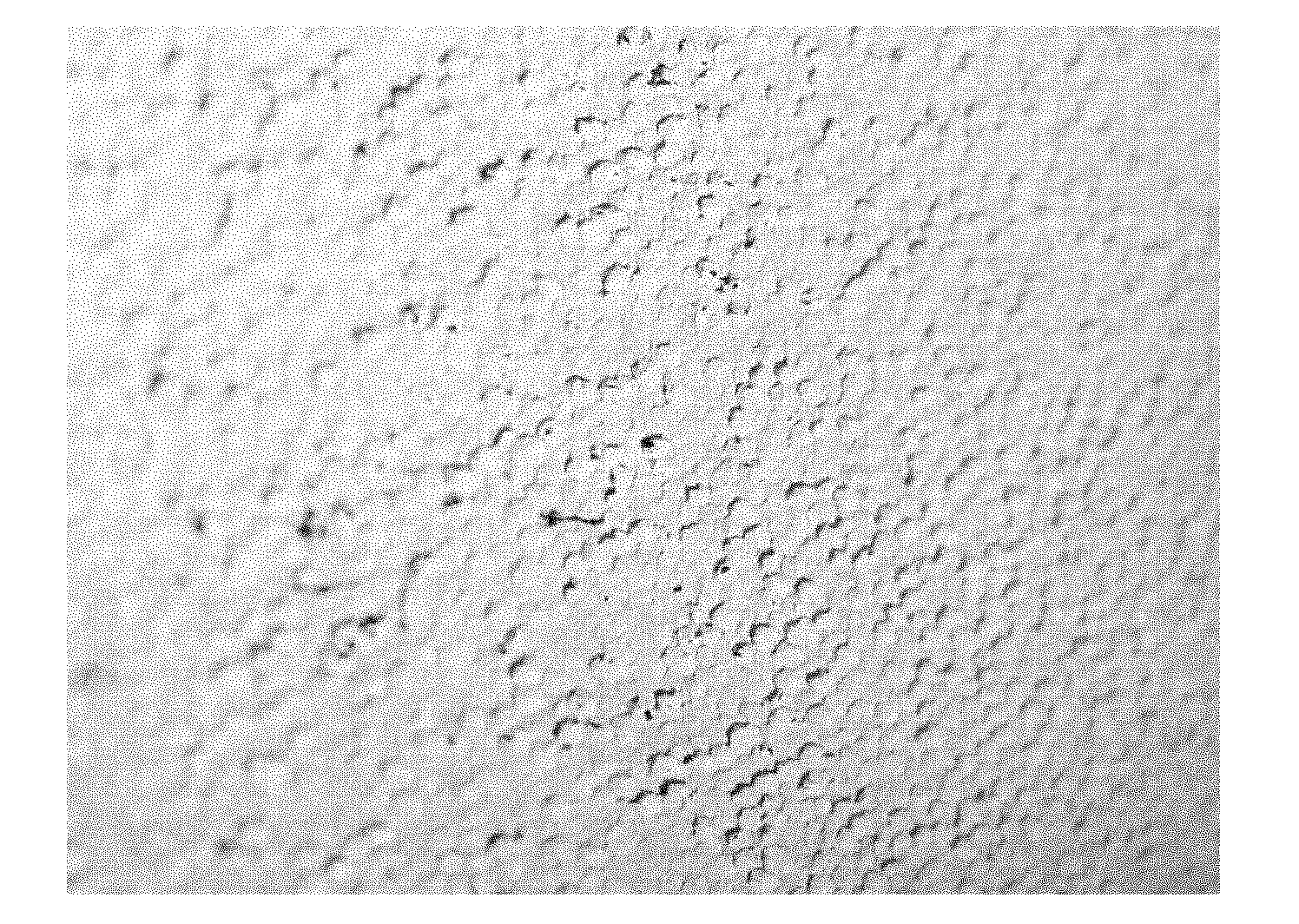

[0035] 1. Put the foamed nickel mesh substrate into ethanol and acetone alternately, ultrasonically clean it three times, and dry it in a blast drying oven.

[0036] 2. Prepare the required hydrofluoric acid / silver nitrate corrosion solution. Hydrofluoric acid and silver nitrate are prepared so that the concentrations are respectively 5.0 mol / L for hydrofluoric acid and 0.02 mol / L for silver nitrate.

[0037] 3. Set the temperature of the water bath to 70°C, tightly combine the metal foam net and the silicon wafer, and immerse it in the heated hydrofluoric acid / silver nitrate solution.

[0038] 4. The metal foam net is corroded in the above solution for 15 minutes, then taken out, rinsed with distilled water and dried.

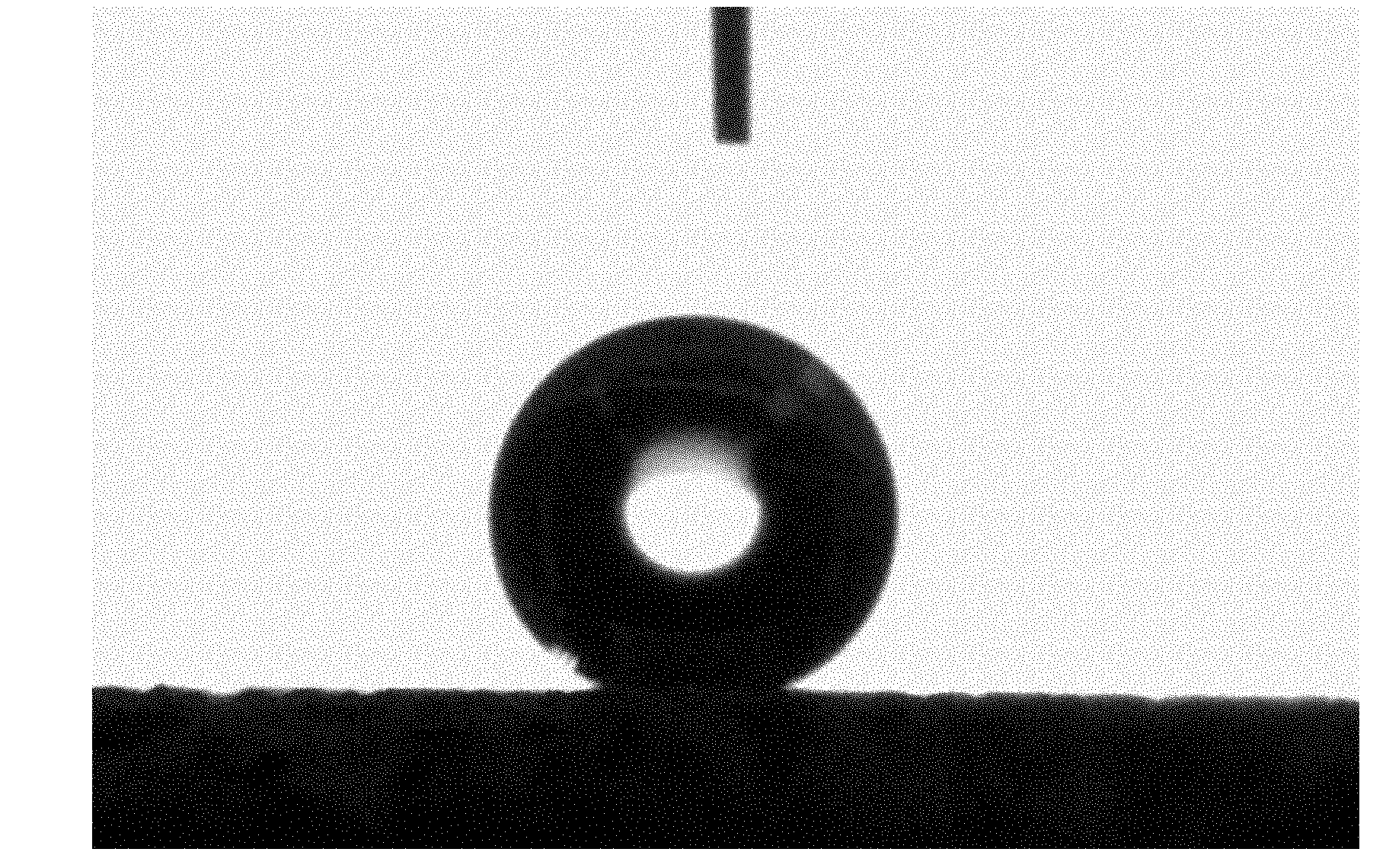

[0039] 5. Soak the dried device in an ethanol solution of low surface energy substance dodecyl mercaptan for 24 hours, take it out, rinse and dry it with distilled water, and obtain a superhydrophobic / superlipophilic device with oil-water separation function....

Embodiment 2

[0042]1. Put the foamed nickel mesh substrate into ethanol and acetone alternately, ultrasonically clean it three times, and dry it in a blast drying oven.

[0043] 2. Prepare the required hydrofluoric acid / silver nitrate corrosion solution. Take hydrofluoric acid and silver nitrate to prepare the concentrations to be 4.0mol / L hydrofluoric acid and 0.02mol / L silver nitrate respectively.

[0044] 3. Set the temperature of the water bath to 70°C, tightly combine the metal foam net and the silicon wafer, and immerse it in the heated hydrofluoric acid / silver nitrate solution.

[0045] 4. The nickel foam is corroded in the above solution for 15 minutes, then taken out, rinsed with distilled water and dried.

[0046] 5. Soak the device after drying in the ethanol solution of low surface energy substance dodecyl mercaptan for 24 hours, take it out, rinse and dry it with distilled water. A superhydrophobic / superlipophilic device with oil-water separation function is obtained.

[00...

Embodiment 3

[0049] 1. Put the foamed nickel mesh substrate into ethanol and acetone alternately, ultrasonically clean it three times, and dry it in a blast drying oven.

[0050] 2. Prepare the required hydrofluoric acid / silver nitrate corrosion solution. Get 40% hydrofluoric acid and silver nitrate to prepare the concentration to be 4.6mol / L hydrofluoric acid and 0.05mol / L silver nitrate respectively.

[0051] 3. Set the temperature of the water bath to 70°C, tightly combine the metal foam net and the silicon wafer, and immerse it in the heated hydrofluoric acid / silver nitrate solution.

[0052] 4. The nickel foam is corroded in the above solution for 10 minutes, then taken out, rinsed with distilled water and dried.

[0053] 5. Soak the device after drying in the ethanol solution of low surface energy substances for 24 hours, take it out, rinse and dry it with distilled water. A superhydrophobic / superlipophilic device with oil-water separation function is obtained.

[0054] The same e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com