Preparation of a triptycene polymer NTP/ zinc cadmium sulfide Cd0.5Zn0.5S composite photocatalyst

A technology of zinc cadmium sulfide and triptycene, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the photocatalytic hydrogen production activity has not been thoroughly studied, etc. The problem is that the preparation conditions are easy to control, the catalytic efficiency is high, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1)Cd 0.5 Zn 0.5 Preparation of S

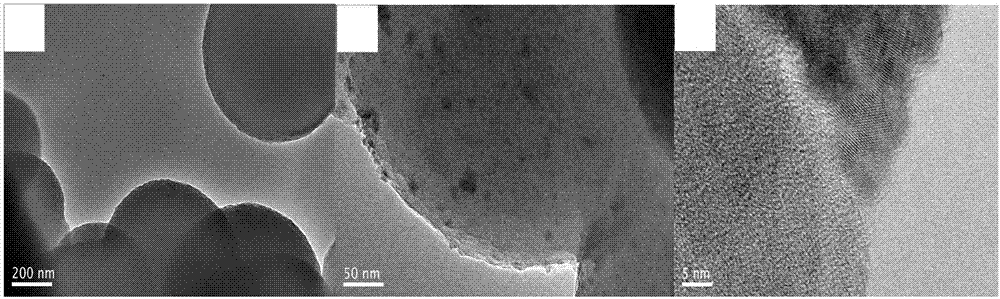

[0032] Na 2 S (1.5608g, 20mmol) was dissolved in 40mL deionized water, and Cd(OAc) was added 2 2H 2 O (2.305g, 10mmol) and Zn(OAc) 2 2H 2 O (1.8348 g, 10 mmol) in 40 mL of an aqueous solution was stirred at room temperature for 24 hours. Then, the product was filtered, washed several times with deionized water, and dried in an oven at 80 °C for 5 h.

[0033] (2) Preparation of NTP

[0034] a: Place triptene (1.25g, 5mmol) in a three-necked flask, add concentrated HNO 3 50 mL, the mixture was heated and stirred at 75° C. for 24 h, and condensed under reflux. The reaction solution was a brown solution, which was cooled to room temperature, then poured into H 2 O (1000 mL) was stirred for 30 min. The precipitate was collected, washed with distilled water, and dried in air. The crude product was purified with dichloromethane / petroleum ether (1:1) as the eluent to give the white solid products 2,6,14-trinitrotriptene (2a) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com