Detection method for separated-out gas in ageing process of high energy solid propellant and device thereof

A solid propellant and aging process technology, applied in the field of analysis and testing, can solve the problems of inability to repeat sampling, difficulty in collection, and low amount of aging gas of propellant, and achieve the effect of improving test efficiency and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

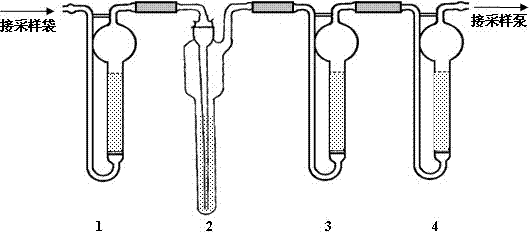

Image

Examples

Embodiment 1

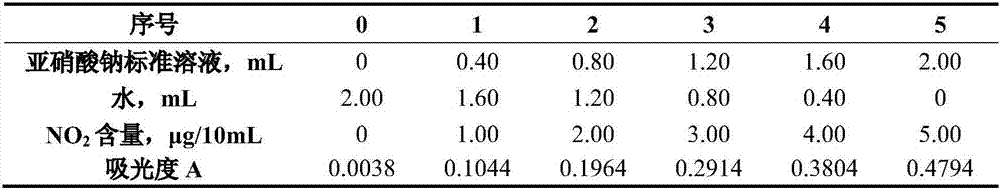

[0034] Calculation of standard curve

[0035] Use superior grade pure sodium nitrite to configure c[NO 2 ]=2.50mg / L standard solution, take 6 10mL colorimetric tubes, pipette sodium nitrite standard solution and water respectively according to Table 1, dilute to the mark with chromogenic agent 1, shake well, keep it in the dark for 30min, use 10mm cuvette, measure the absorbance A at the peak wavelength of the spectrophotometer at 540-545nm, the results are shown in Table 1. Take the absorbance value after subtracting the blank, and NO 2 The content value C (μg / 10mL) was linearly fitted to obtain the standard curve equation: A=0.0943C+0.0029, and the linear correlation coefficient r=0.9998.

[0036] Table 1 NO 2 Standard solution series

[0037]

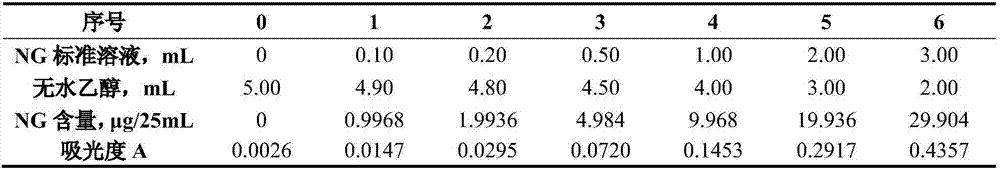

[0038] Prepare c[NG]=9.97mg / L ethanol standard solution with nitroglycerin, take six 25mL colorimetric tubes, pipette NG standard solution and absolute ethanol according to Table 2, add 0.5mL potassium hydroxide solution, and pl...

Embodiment 2

[0048] The calculation of the standard curve is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com