Model establishing method for predicting foam retention of draft beer in shelf life based on broth and prediction method thereof

A technology of model building and fermented liquid, which is applied in the direction of material analysis, food testing, and beverage testing through optical means, to achieve good prediction accuracy, good reproducibility, and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, preferred embodiments of the present invention are described in detail below.

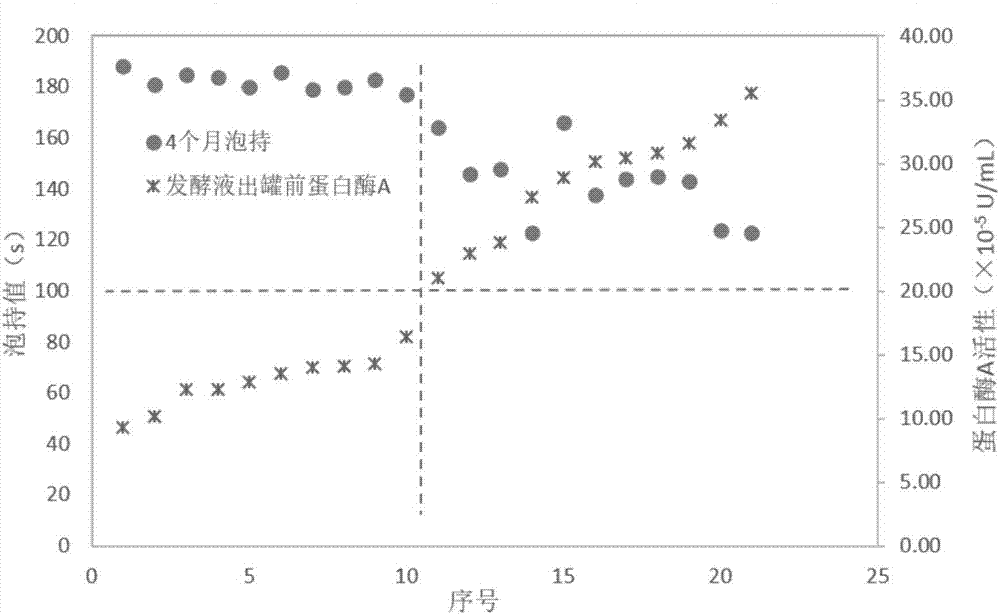

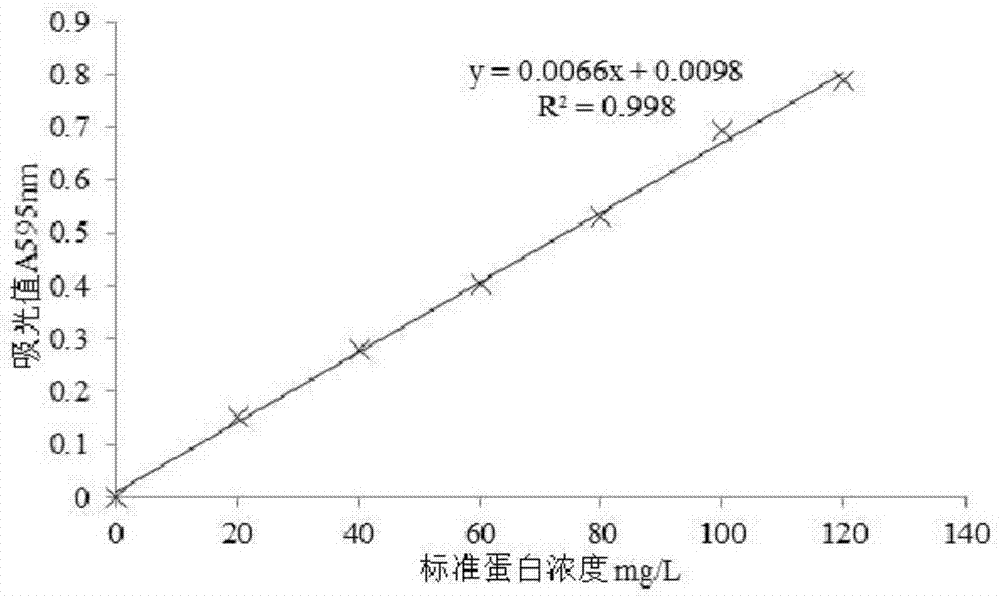

[0048] Principle of the present invention: the most important factor that influences pure draft beer foam retention is exactly the content of foam protein and the activity of protease A, therefore, by measuring the relation between these two factors and shelf life foam retention, by establishing Fitting the model, by measuring the foam protein content and protease A activity in the fermentation broth in advance, the foam retention of pure draft beer can be accurately predicted during the shelf life.

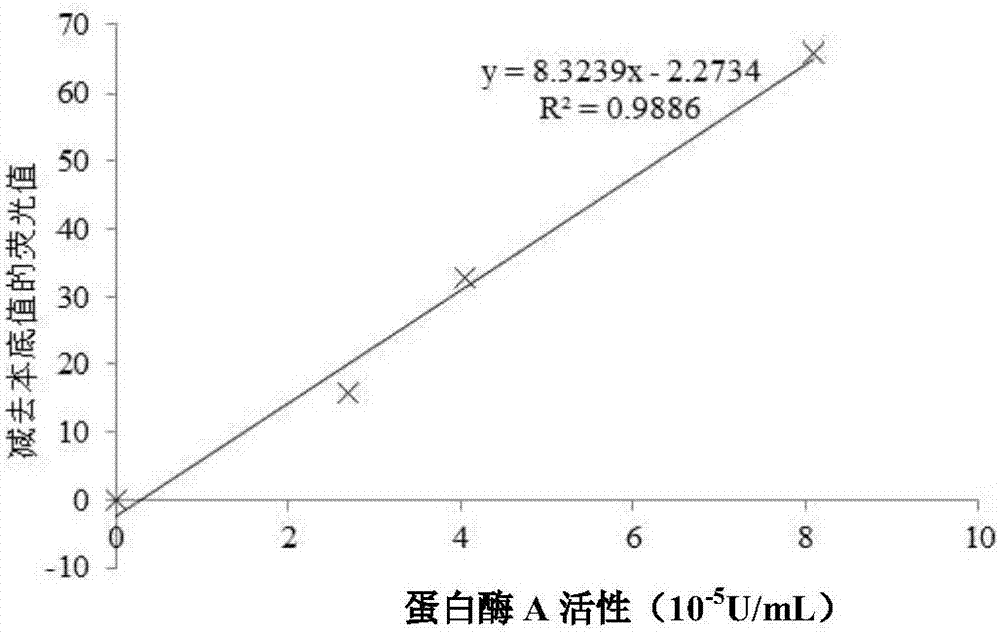

[0049] 1. Determination of protease A activity in fermentation broth samples and analysis of its relationship with pure draft beer shelf-life infusion retention 1. Establishment of protease A activity standard curve

[0050] Take the activity as 0, 2, 4, 6, 8, 10×10 -5 40 μL of protease A standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com