Lighting uniformity correction device, lighting uniformity correction method and exposure projection system

A uniformity correction and projection system technology, which is applied in the field of lithography lighting, can solve the problems affecting the production rate and the difficulty in the process of the variable gray compensation plate, so as to achieve the effects of increasing the production rate, maintaining the uniformity of the pupil, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

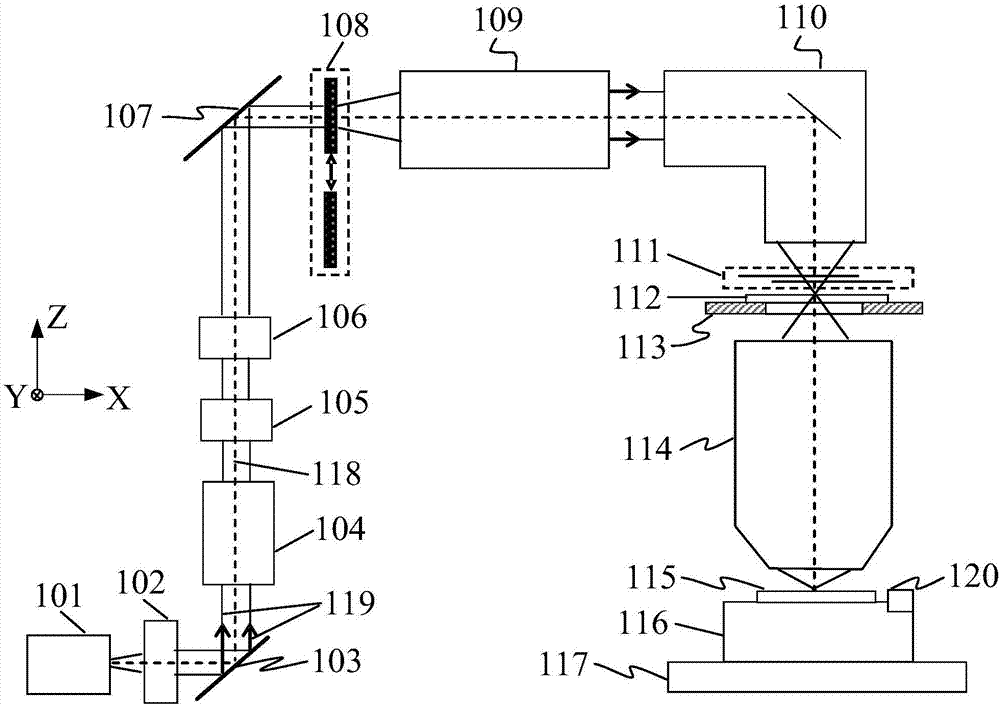

Method used

Image

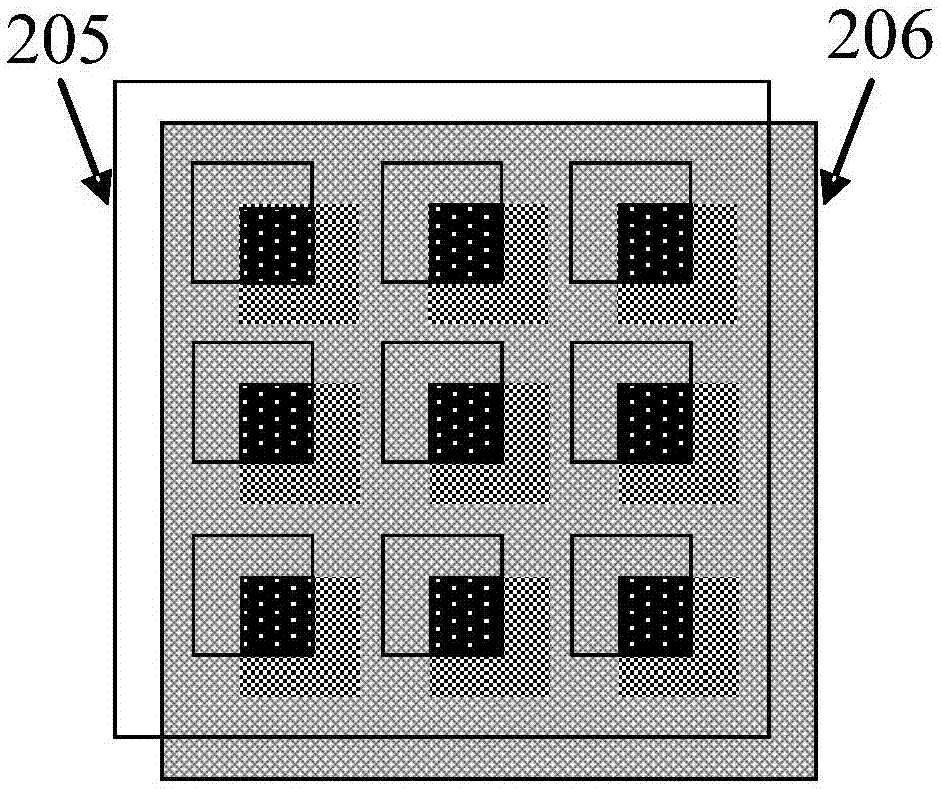

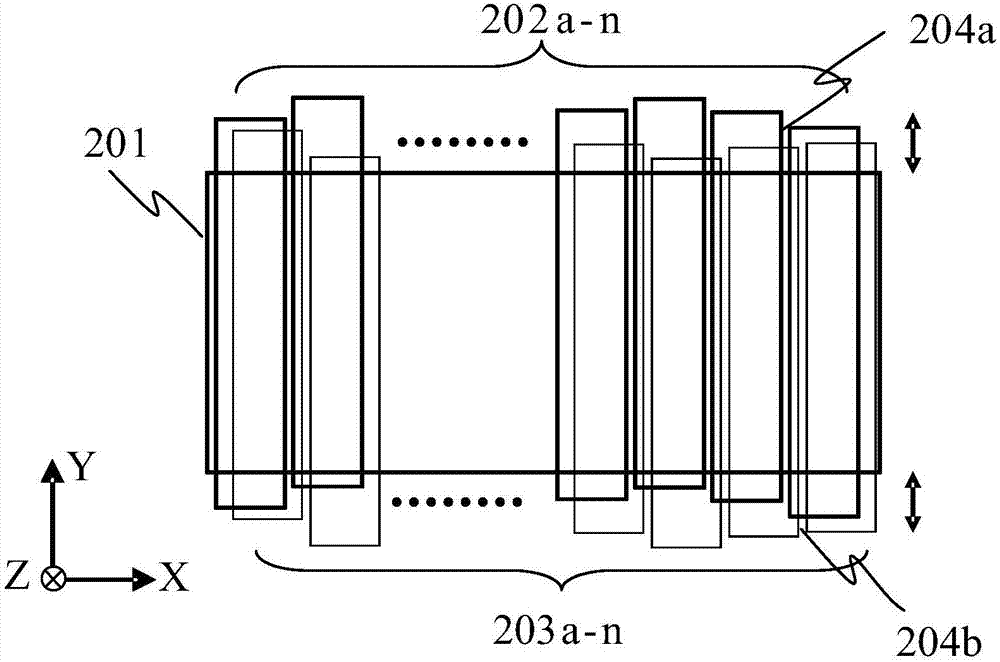

Examples

Embodiment 2

[0101] Please focus on reference Figure 13 The difference between this embodiment and Embodiment 1 is that the specific structure of the third module 110 is different. The third module 110 in this embodiment specifically includes a uniform light component, and the uniform light component in this embodiment adopts a quartz rod or a quartz rod Combination 601, combined with variable shading knife-edge array pair 602, variable knife-edge assembly 603, and condenser lens group 503, the light beam 119 is incident on the mirror array 504 after passing through the condenser lens group 503, and the pupil is imaged to the reticle 112 and illuminate the pattern on the reticle 112 . In order to obtain a trapezoidal illumination field distribution in the scanning direction (ie, the Y direction), the position of the reticle 112 deviates from the rear focal plane of the condenser lens group 503 , and this embodiment can also achieve the function of modulating the illumination light intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com