A kind of silicon/carbon powder composite material and its preparation method and battery negative electrode material

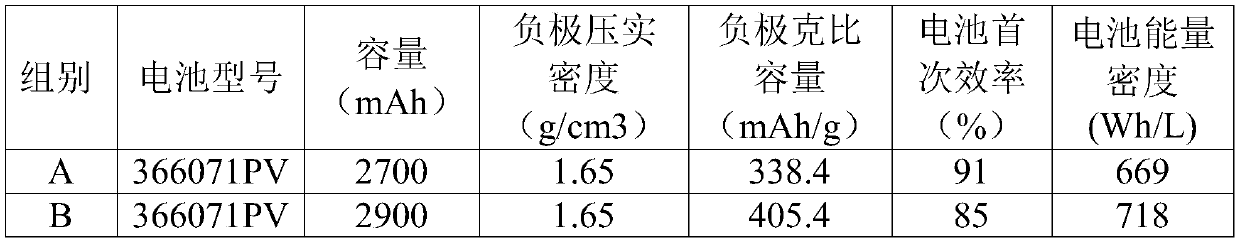

A composite material and carbon powder technology, applied in the field of battery negative electrode materials and their preparation, can solve the problems of large and non-uniform particle size, poor sphericity of silicon/carbon composite material powder, etc., achieve uniform powder particle size and improve cycle performance , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

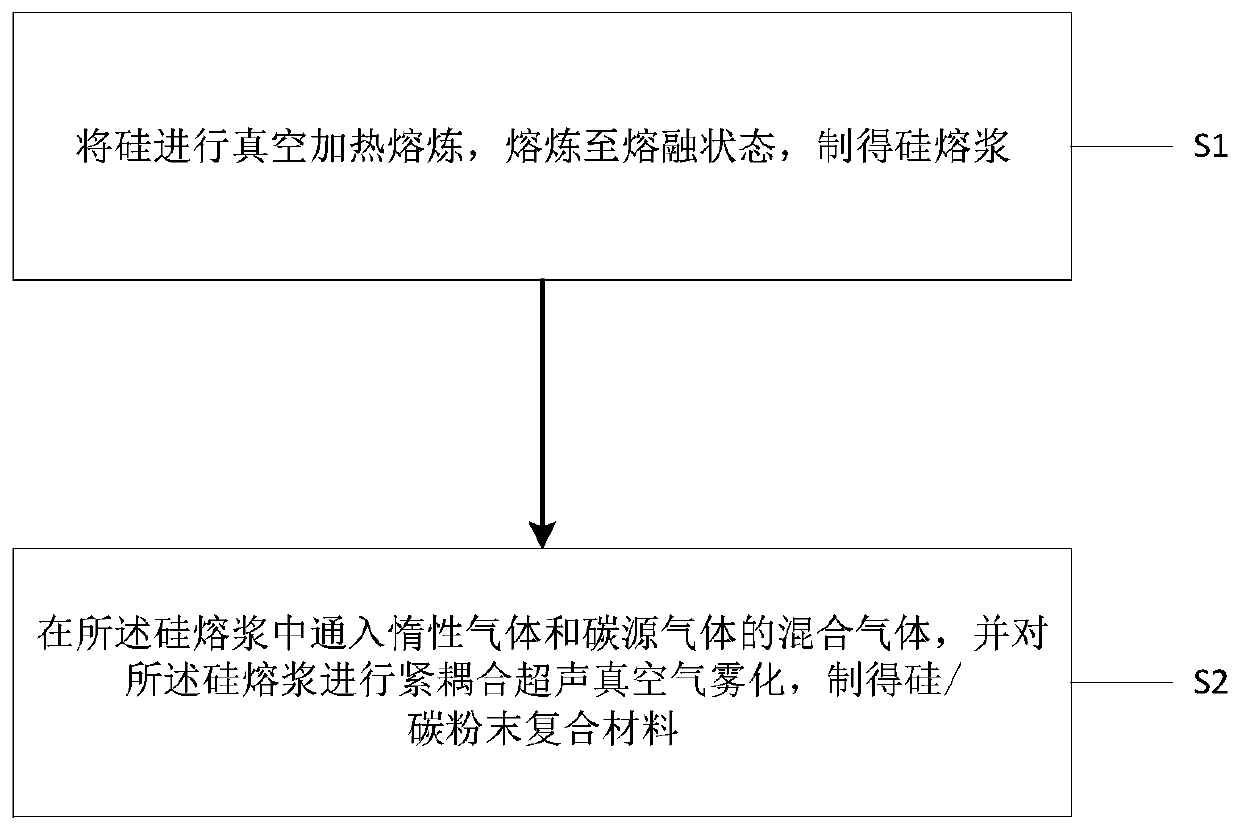

[0021] Such as figure 1 Shown, the preparation method of silicon / carbon powder composite material of the present invention comprises the following steps:

[0022] S1. Melting the silicon under vacuum heating until it reaches a molten state to obtain a silicon melt.

[0023] Specifically, silicon is put into a close-coupled ultrasonic vacuum atomization device, and heated and smelted under vacuum conditions. The melting temperature is preferably 1520-1560 ° C. When it is observed that the silicon is smelted to a molten state, stop heating to obtain silicon Magma. During smelting, more preferably, the degree of vacuum is 0-5Pa. In this step, it is also included to keep the prepared silicon melt, so that the silicon can be fully melted, and avoid the cooling and solidification of the silicon melt ejected from the atomizing nozzle, so that the silicon melt remains in a molten state; The heat preservation time is preferably 25 to 35 minutes.

[0024] Wherein, the silicon conten...

Embodiment 1

[0032] Put 50kg of silicon into the crucible of close-coupled ultrasonic gas atomization equipment, heat and melt the silicon at a temperature of 1520°C under the condition of a vacuum degree of less than 5 Pa, and melt it to a molten state to obtain a silicon melt. And the silicon molten slurry is kept warm for 25 minutes.

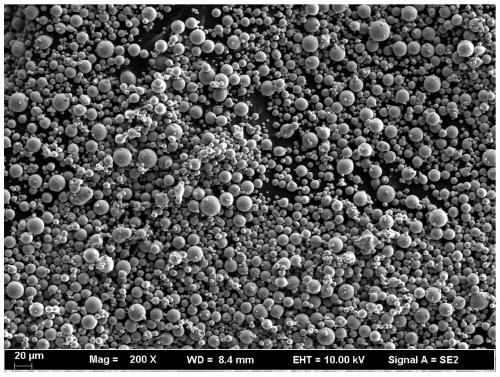

[0033] Atomize the silicon melt, choose nitrogen as the carrier gas, and choose acetylene as the carbon source gas; pass the mixed gas of nitrogen and acetylene with a volume ratio of 85:15 into the mixing pipe in the close-coupled ultrasonic gas atomization equipment for mixing ; and the mixed gas pipeline is connected to the atomizing nozzle in the close-coupled ultrasonic gas atomization equipment, the silicon melt is sprayed out through the atomizing nozzle, meets the airflow of the mixed gas, and the inlet pressure of the mixed gas is controlled to be 3.5Mpa, and the acetylene The carbon in the silicon powder is separated and coated on the surface of...

Embodiment 2

[0035] Put 50kg of silicon into the crucible of the close-coupled ultrasonic vacuum atomization equipment, heat and melt the silicon at a temperature of 1540°C under the condition that the vacuum degree is lower than 5pa, and melt it to a molten state to obtain silicon Melt, and heat preservation of the silicon melt, the heat preservation time is 30min.

[0036] Atomize the silicon melt, select nitrogen as the carrier gas, and select methane as the carbon source gas; pass the mixed gas of nitrogen and acetylene with a volume ratio of 85:20 into the mixed gas pipeline in the close-coupled ultrasonic vacuum air atomization equipment Mixing; and the mixed gas pipeline is connected to the atomizing nozzle in the close-coupled ultrasonic vacuum atomization equipment. Once the silicon melt is sprayed out from the atomizing nozzle, it meets the airflow of the mixed gas, and the inlet pressure of the mixed gas is controlled to be 4Mpa. , the carbon in the methane is separated and coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com