A preparation method of remote fluorescent sheet based on low melting point borosilicate glass powder

A borosilicate glass, borosilicate technology, applied in the field of materials science, can solve the problems of organic glue aging, uneven coating of phosphor powder, yellowing, etc., and achieves not easy to fall off, high practical value, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

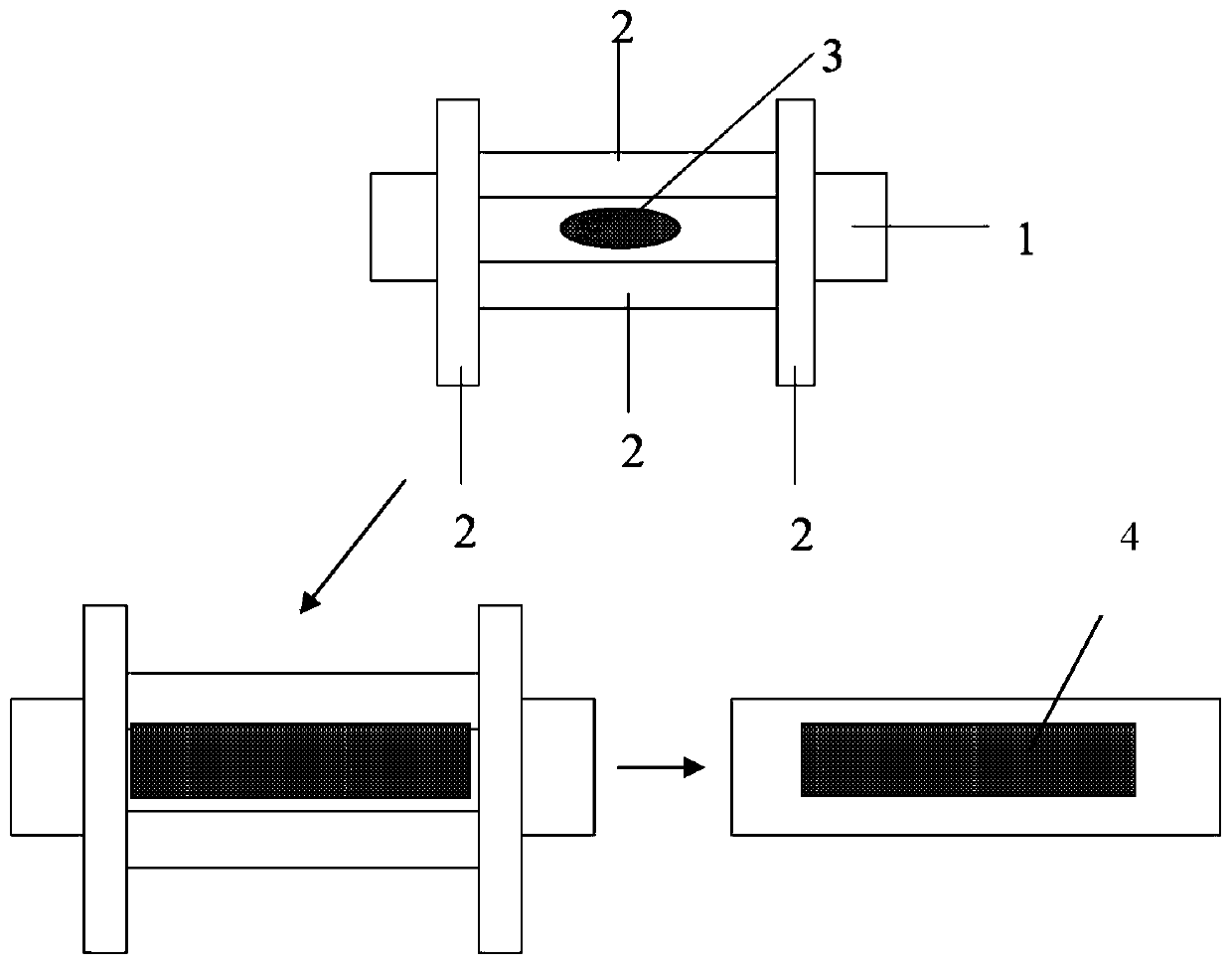

Method used

Image

Examples

Embodiment 1

[0023] 1) SiO to be weighed 2 , B 2 O 3 , ZnO, Na 2 CO 3 The mass percentages of the raw materials are: 15%, 44%, 21%, 20%, mixed uniformly, prepared glass blocks by the melting method, and ground into powders with a particle size of 5 to 13 μm;

[0024] 2) Weigh 20 parts by mass and 5 parts of glass powder and phosphor powder, disperse the powder in an organic substance with a mass ratio of 45 parts, and mix them uniformly to form a fluorescent glass paste;

[0025] 3) Coat the fluorescent glass slurry prepared in 2) on the ultra-white glass plate with a blade coating technique;

[0026] 4) The fluorescent glass layer prepared in 3) is fully sintered at 180°C to 300°C to completely volatilize the organic matter, and then sintered at a low temperature of 600°C to 700°C for 5 to 30 minutes to obtain the remote fluorescent glass sheet.

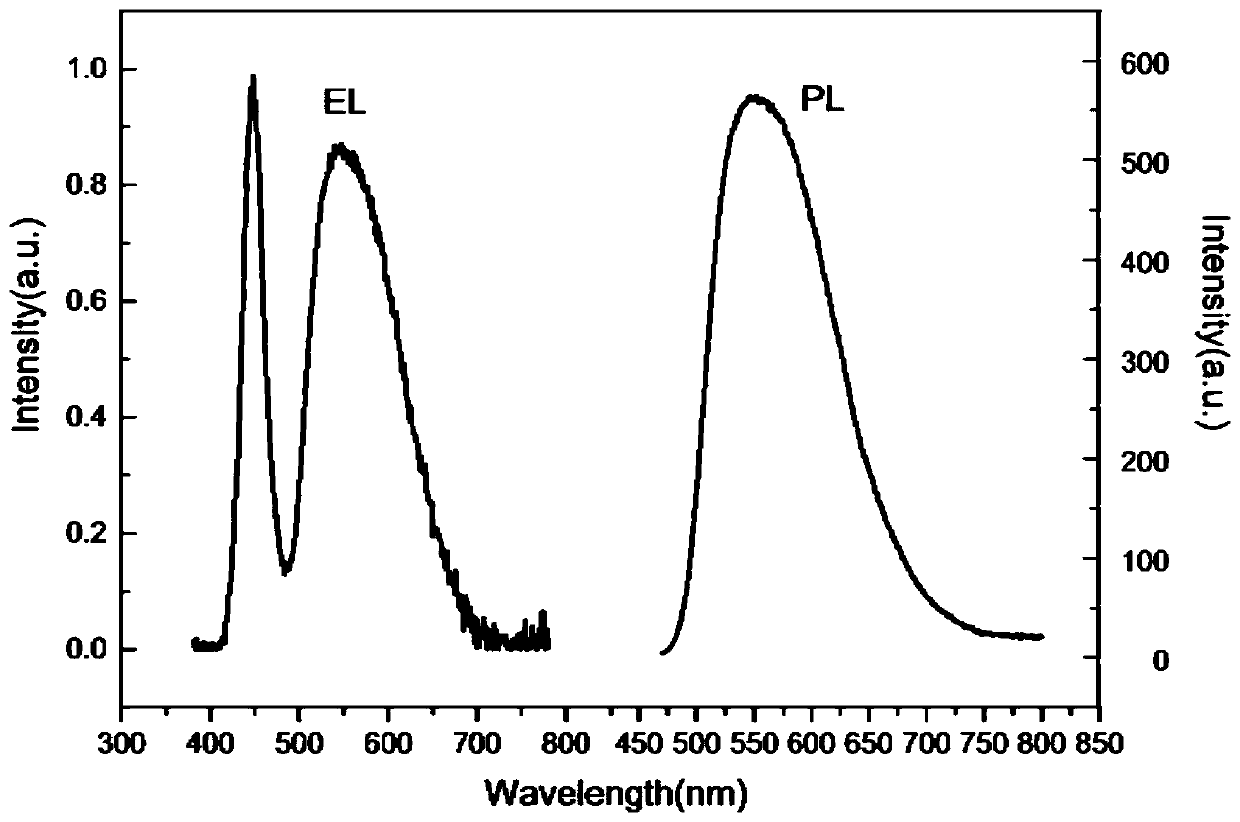

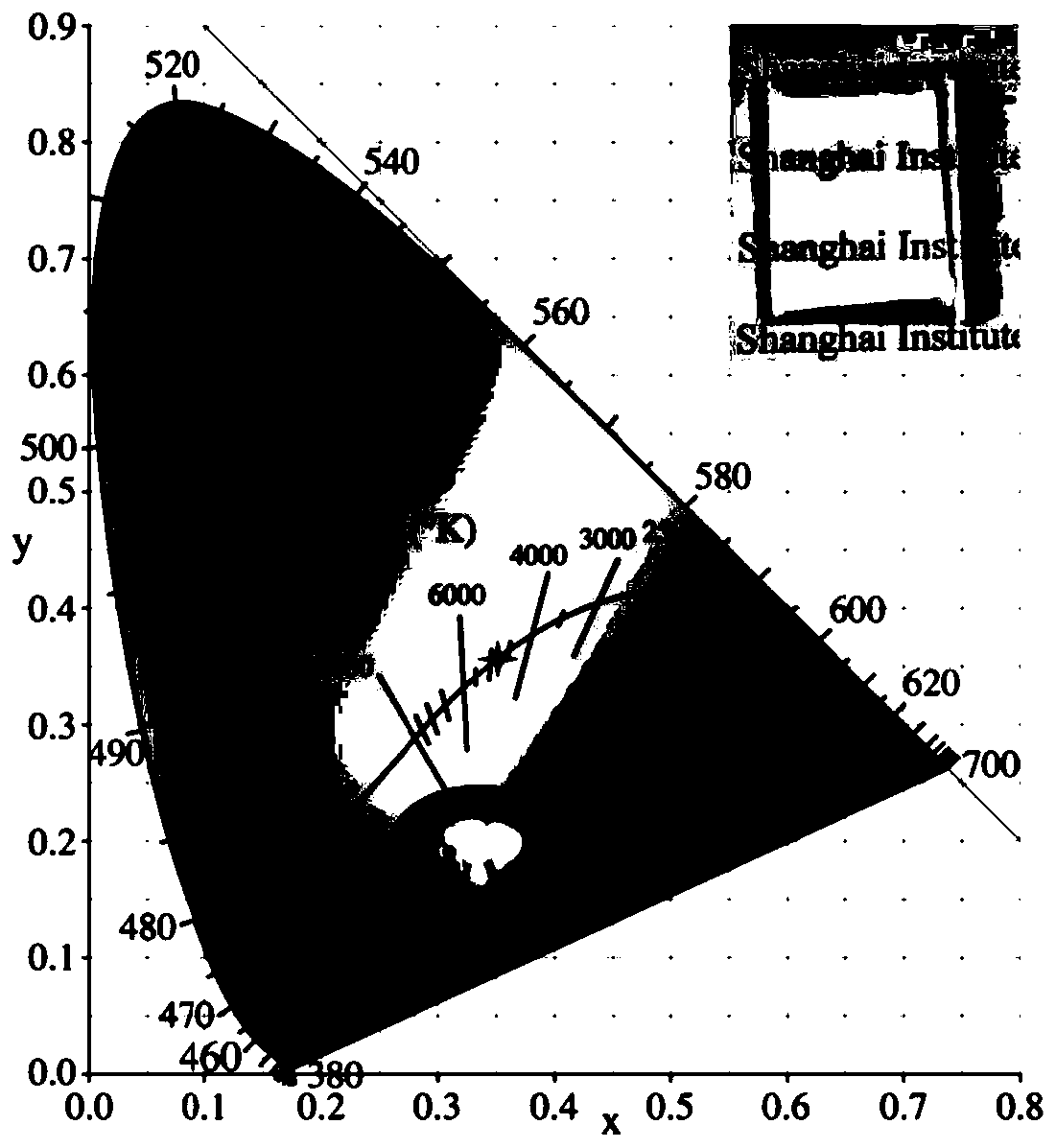

[0027] by figure 2 It can be seen that under the excitation wavelength of 460nm, the fluorescent glass sheet appears Ce at 550nm 3+ The characteristic ...

Embodiment 2

[0029] 1) SiO to be weighed 2 , B 2 O 3 , ZnO, Na 2 CO 3 The mass percentages of the raw materials are: 18.5%, 45%, 20.5%, 16%, mixed evenly, prepared glass blocks by the melting method, and ground into powders with a particle size of 5-13μm;

[0030] 2) Weigh 32 parts by mass and 6 parts of glass powder and phosphor powder, disperse the powder in 52 parts by mass of organic matter, and evenly mix it into a fluorescent glass paste;

[0031] 3) Coating the fluorescent glass slurry prepared in 2) on the ultra-white glass plate by spin coating technology;

[0032] 4) The fluorescent glass layer prepared in 3) is fully sintered at 180°C to 300°C to completely volatilize the organic matter, and then sintered at a low temperature of 600°C to 700°C for 5 to 30 minutes to obtain the remote fluorescent glass sheet.

Embodiment 3

[0034] 1) SiO to be weighed 2 , B 2 O 3 , ZnO, Na 2 CO 3 The mass percentages of the raw materials are: 20.5%, 44.8%, 21.2%, 13.5%, mixed uniformly, prepared glass blocks by melting method, and ground into powder with a particle size of 5-13μm;

[0035] 2) Weigh 48 parts by mass and 9 parts of glass powder and phosphor powder, disperse the powder in 67 parts by mass of organic matter, and evenly mix it into a fluorescent glass paste;

[0036] 3) Coating the fluorescent glass paste prepared in 2) on the ultra-white glass plate by screen printing technology;

[0037] 4) The fluorescent glass layer prepared in 3) is fully sintered at 180°C to 300°C to completely volatilize the organic matter, and then sintered at 600°C to 700°C for 5 to 30 minutes to obtain the remote fluorescent glass sheet

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com