Oxynitride phosphor powder, preparation method thereof, and LED light source comprising the phosphor powder

An LED light source and oxynitride technology, applied in the field of phosphors, can solve the problems of reduced luminous intensity and thermal stability of phosphors, and achieve the effects of increased luminous intensity and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] It is prepared by adopting the material formula of the prior art and matching the preparation steps in the present invention, and using this as a benchmark to illustrate the influence of the addition of nano-BN on the morphology, structure and optical properties of the phosphor powder.

[0035] Step (1) Weighing raw materials. to Y 2 o 3 , Nano α-Al 2 o 3 and CeO 2 According to chemical formula Y 2.925 Ce 0.075 al 5 o 12 The strict proportion of ingredients, weigh 3.30g of Y 2 o 3 , 2.55g of α-Al 2 o 3 , 0.13g CeO 2 and 0.06g co-solvent NH 4 F, the purity of the above raw materials is 99.99% or 99.9995%, that is, 4N or 5N, co-solvent NH 4 F is analytically pure, chemical formula Y 2.925 Ce 0.075 al 5 o 12 Ce in 3+ = 2.5at%.

[0036] In the present invention, "pure oxides of M and Re" refer to high-purity oxides with a purity of 99.99% or 99.9995%.

[0037] Step (2), at first above-mentioned four kinds of raw materials are put into polytetrafluoroeth...

Embodiment 2

[0042] The following starting materials of 4N or 5N: Y 2 o 3 , Nano α-Al 2 o 3 , CeO 2 and nano-amorphous BN according to chemical formula Y 2.925 Ce 0.075 al 4.7 B 0.3 o 11.7 N 0.3 The strict proportion of ingredients, weigh 3.30g of Y 2 o 3 , 2.40g of α-Al 2 o 3 , 0.07g BN, 0.13g CeO 2 and 0.06g of NH 4 F as co-solvent, where Ce 3+ =2.5at%, the relative content of BN is 0.3mol.

[0043] Put the above five kinds of initial raw materials into a polytetrafluoroethylene ball mill jar, add 5ml of absolute ethanol 0.8 times the weight of the initial raw materials and 23.8g of φ3mm zirconia balls 4 times the weight of the initial raw materials, and fully grind for 3-5 hours; The precursor slurry is placed in a vacuum drying oven at 80-120°C for 10-20 hours to obtain a dry oxide precursor containing partial agglomerates; Gently grind, pulverize, and pass through a 200-mesh sieve in a mortar, and the under-sieve is the oxide precursor; finally, put the above oxide pr...

Embodiment 3

[0046] The following starting materials of 4N or 5N: Y 2 o 3 , Nano α-Al 2 o 3 , CeO 2 and nano-amorphous BN according to chemical formula Y 2.925 Ce 0.075 al 4.5 B 0.5 o 11.5 N 0.5 The strict proportion of ingredients, where Ce 3+ =2.5at%, the relative content of BN is 0.5mol. 3.30g of Y 2 o 3 , 2.30g of α-Al 2 o 3 , 0.12g BN, 0.13g CeO 2 and 0.06 g of co-solvent NH 4 F is prepared according to the process described in Example 2 to obtain a yellow-green Y that can be effectively excited by ultraviolet to blue light 2.925 al 4.5B 0 . 5 o 11.5 N 0.5 : Ce phosphor.

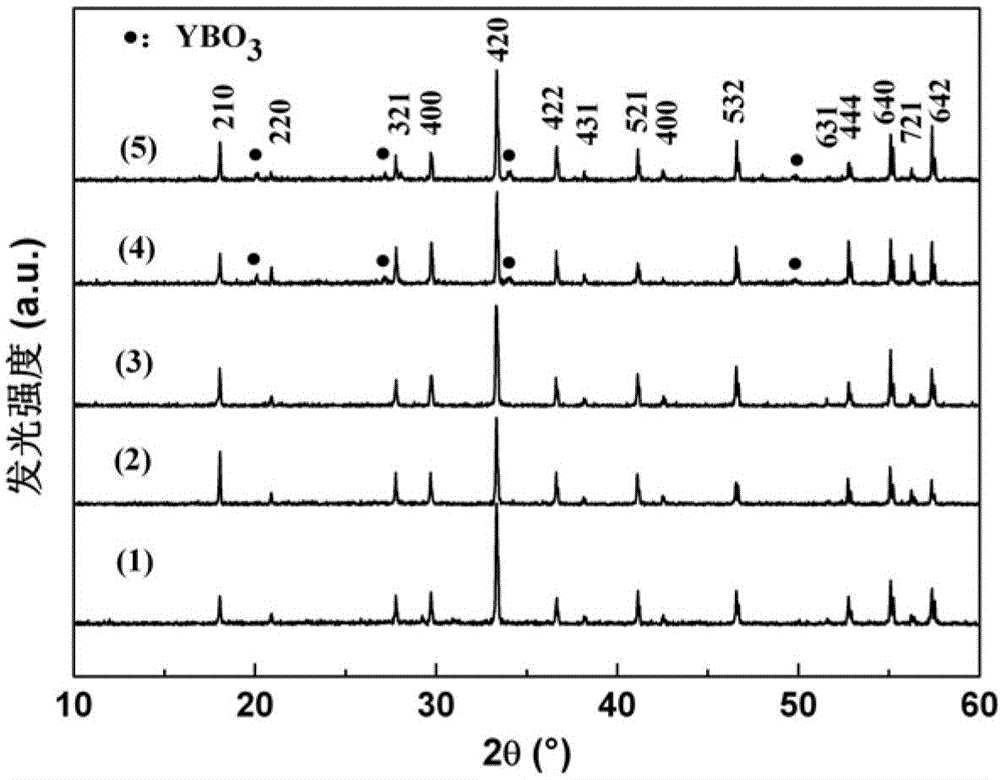

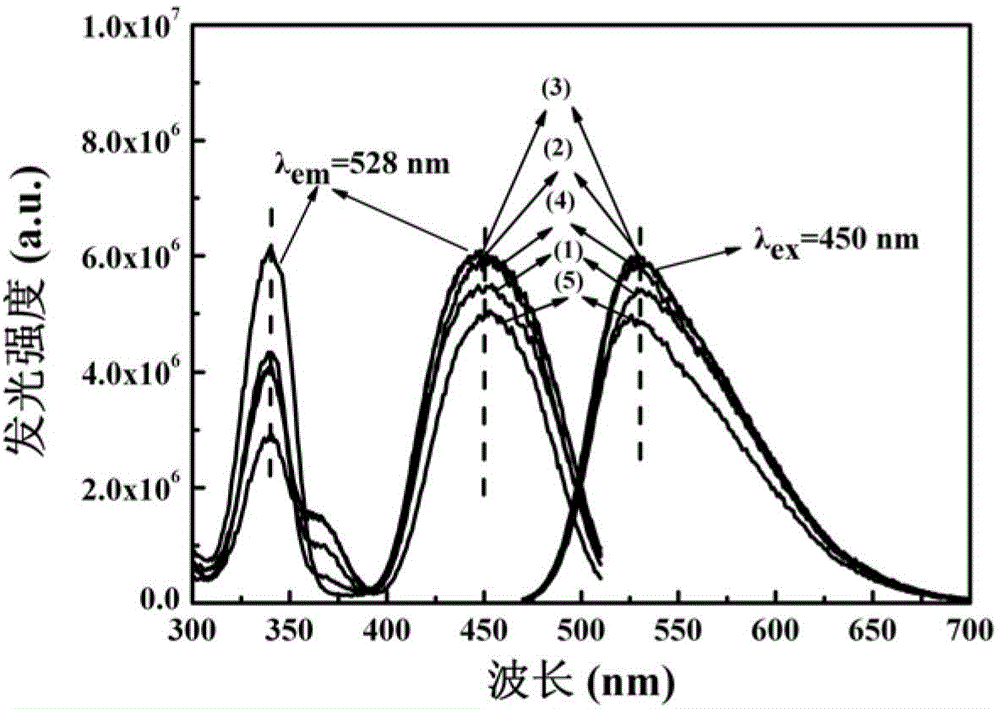

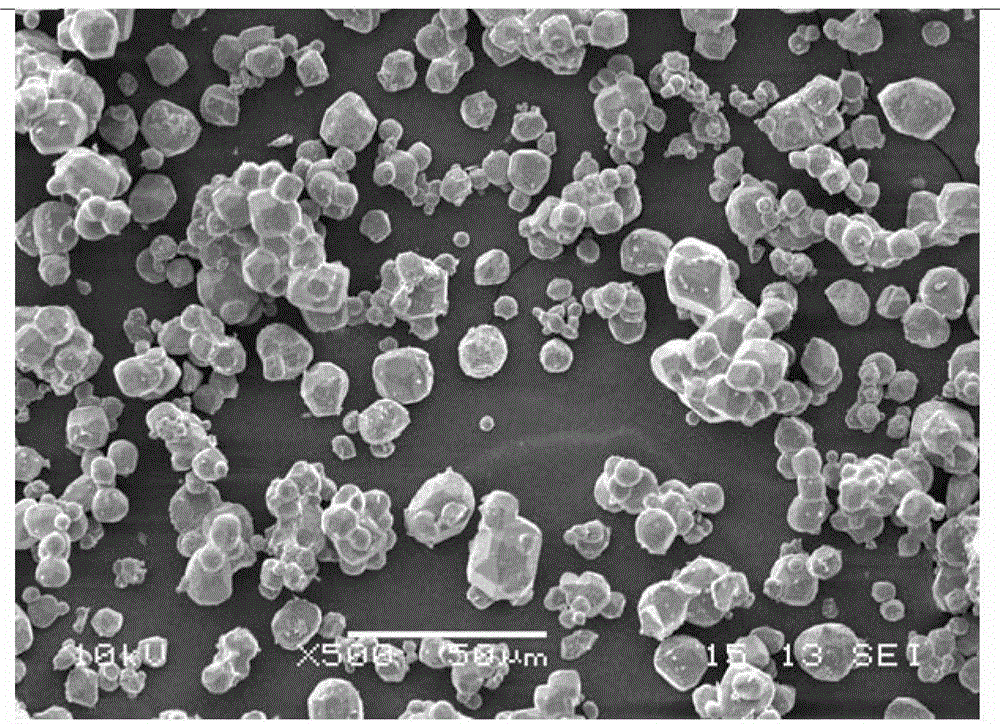

[0047] like Figure 4 As shown, after adding BN with a relative content of 0.5mol, a pure garnet-structured YAG phase can still be obtained, and its grains grow further, with an average grain size of about 35 μm. Under the excitation of blue light, it emits yellow-green light with a dominant wavelength of 527nm, and the luminous intensity is equivalent to that of the sample added with 0.3mol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com