Calcium aluminate glass kiln tin bath suspended ceiling brick and preparation method thereof

A glass furnace and calcium aluminate technology, applied in the field of refractory materials, can solve the problems of low high-temperature creep rate, low thermal conductivity, and low porosity, and achieve low high-temperature creep rate, low thermal conductivity, and low porosity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

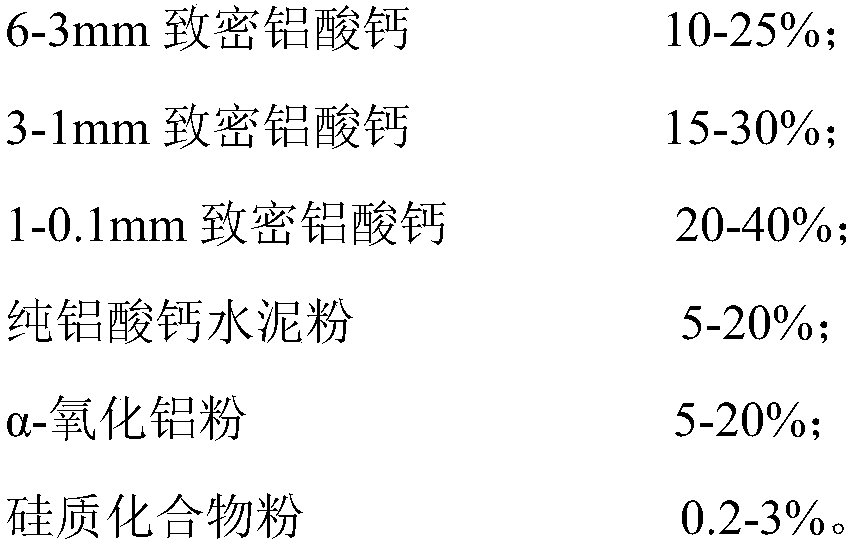

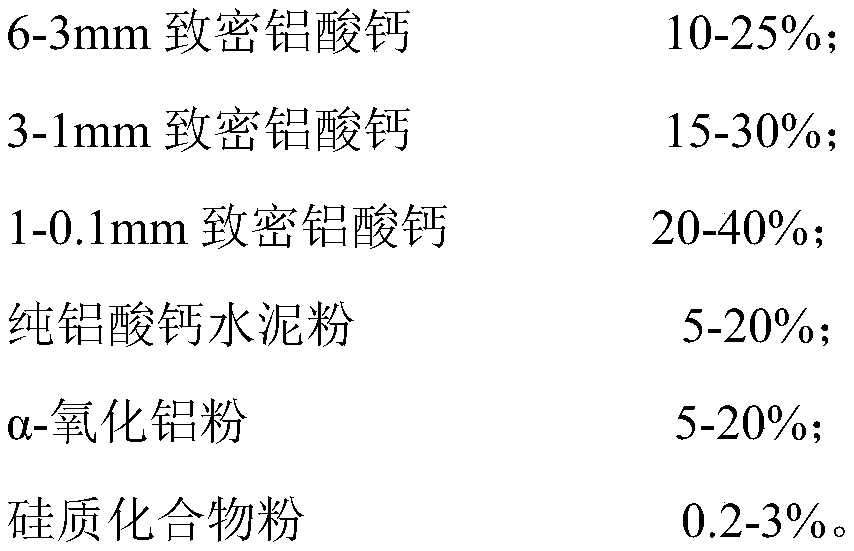

Method used

Image

Examples

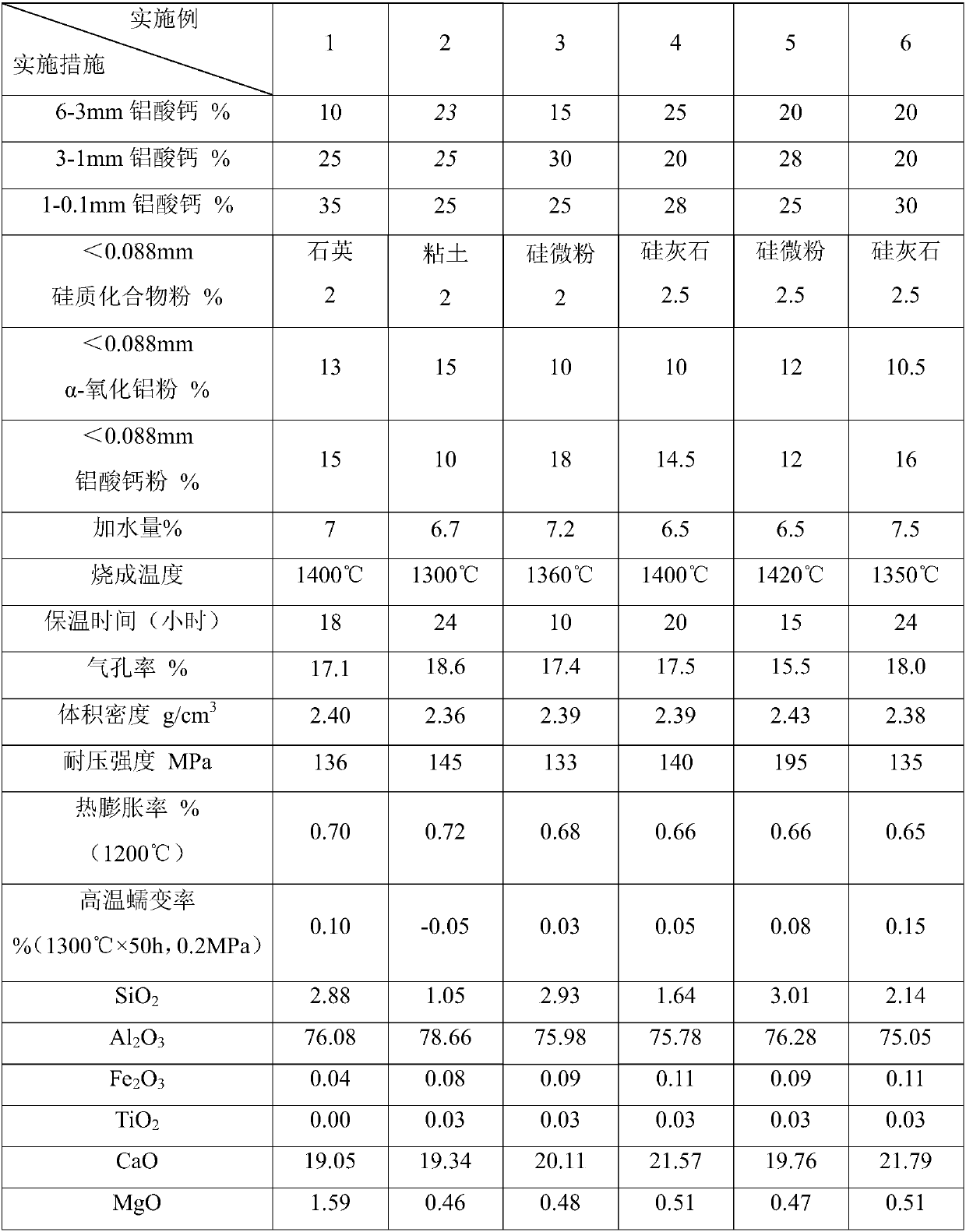

Embodiment 1-6

[0037] Add the raw materials in the formula in Table 2 into the mixer according to the proportion, mix for 5-15 minutes, add water and mix for 3-5 minutes, then pour the mud into the mold for vibration molding, and let the green body dry naturally after demoulding After 1-3 days, dry at 110°C and fire at 1250°C-1450°C to obtain calcium aluminate tin bath bottom brick samples. The firing system is as follows:

[0038] 10-200°C, heating rate 1°C / min;

[0039] 200-650°C, heating rate 1.5°C / min;

[0040] 650-1000°C, heating rate 1.5°C / min;

[0041] 1000-1250°C, heating rate 2°C / min;

[0042] 1250-1450 ℃ heat preservation, heat preservation time is 8-30 hours;

[0043] Stop fire to cool down, and cool down naturally with the kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com