HNBR sealing material for hydraulic cylinder U-shaped ring, preparation method and application of HNBR sealing material

A technology of hydraulic cylinder and rubber seal, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of NBR rubber heat resistance, poor ozone resistance, short life of seals, and poor modulus retention ability. , to achieve the effect of good compatibility, good rebound and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

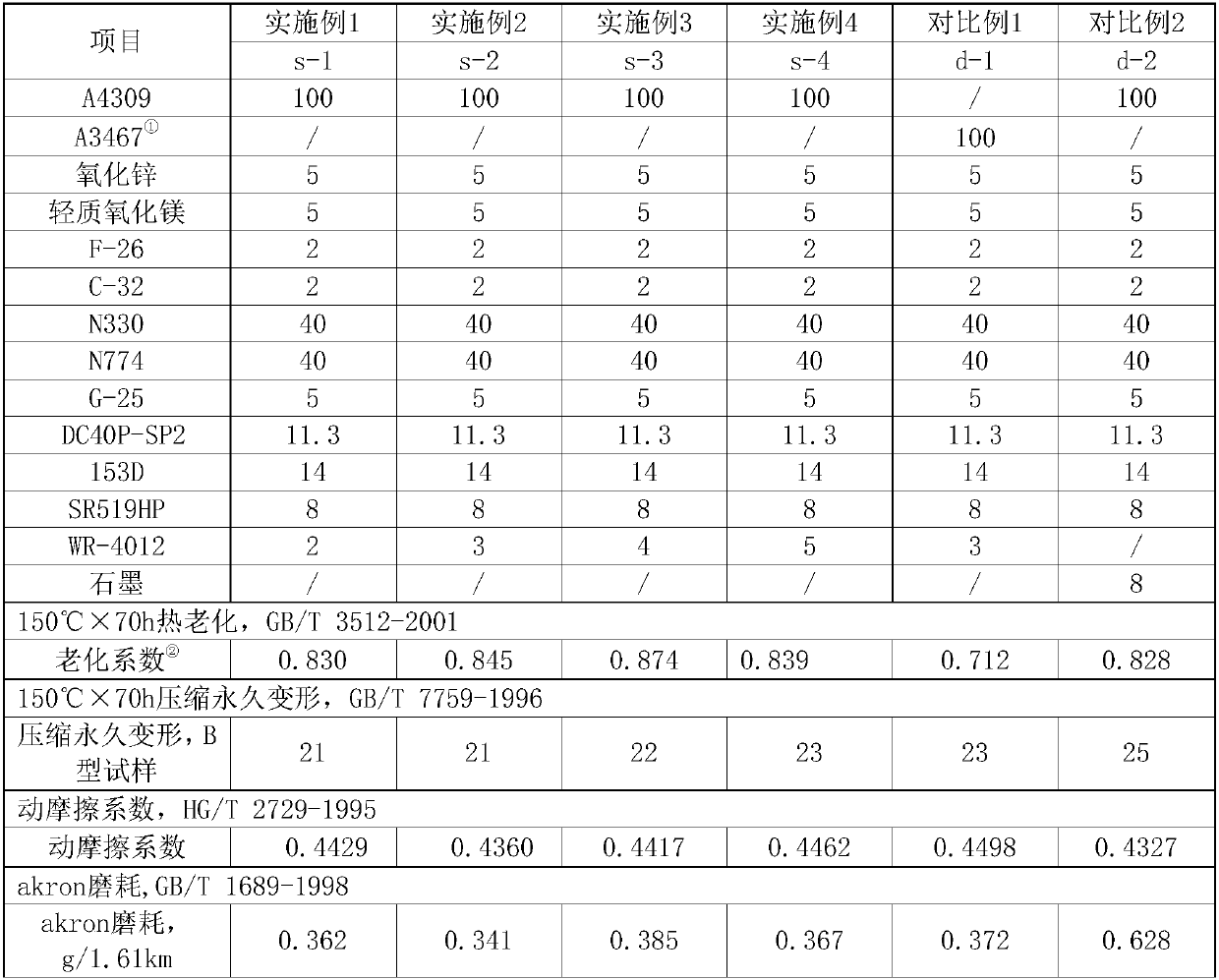

Embodiment 1

[0039] A kind of HNBR rubber sealing material for the U-shaped ring of a hydraulic cylinder, it is made of the following raw materials in parts by weight:

[0040] 100 parts of HNBR rubber Therban A4309, 5 parts of zinc oxide, 5 parts of light magnesium oxide, 2 parts of antioxidant F-26, 40 parts of carbon black N330, 40 parts of carbon black N774, 2 parts of processing aid C-32, 5 parts Plasticizer G-25, 11.3 parts of crosslinking agent DC40P-SP2, 14 parts of co-crosslinking agent 153D, 8 parts of co-crosslinking agent SR519HP, 2 parts of wear-resistant agent WR-4012.

Embodiment 2

[0042] A kind of HNBR rubber sealing material for the U-shaped ring of a hydraulic cylinder, it is made of the following raw materials in parts by weight:

[0043] 100 parts of HNBR rubber Therban A4309, 5 parts of zinc oxide, 5 parts of light magnesium oxide, 2 parts of antioxidant F-26, 40 parts of carbon black N330, 40 parts of carbon black N774, 2 parts of processing aid C-32, 5 parts Plasticizer G-25, 11.3 parts of crosslinking agent DC40P-SP2, 14 parts of co-crosslinking agent 153D, 8 parts of co-crosslinking agent SR519HP, 3 parts of wear-resistant agent WR-4012.

Embodiment 3

[0045] A kind of HNBR rubber sealing material for the U-shaped ring of a hydraulic cylinder, it is made of the following raw materials in parts by weight:

[0046] 100 parts of HNBR rubber Therban A4309, 5 parts of zinc oxide, 5 parts of light magnesium oxide, 2 parts of antioxidant F-26, 2 parts of processing aid C-32, 40 parts of carbon black N330, 40 parts of carbon black N774, 5 parts Plasticizer G-25, 11.3 parts of crosslinking agent DC40P-SP2, 14 parts of co-crosslinking agent 153D, 8 parts of co-crosslinking agent SR519HP, 4 parts of wear-resistant agent WR-4012.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com