Preparation method of Kumquat red spider insecticidal solution

A technology of red spider and insecticidal liquid, applied in the field of pesticides, can solve problems such as harm to human and animal health, residues, etc., and achieve the effects of increasing residence time, prolonging action time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

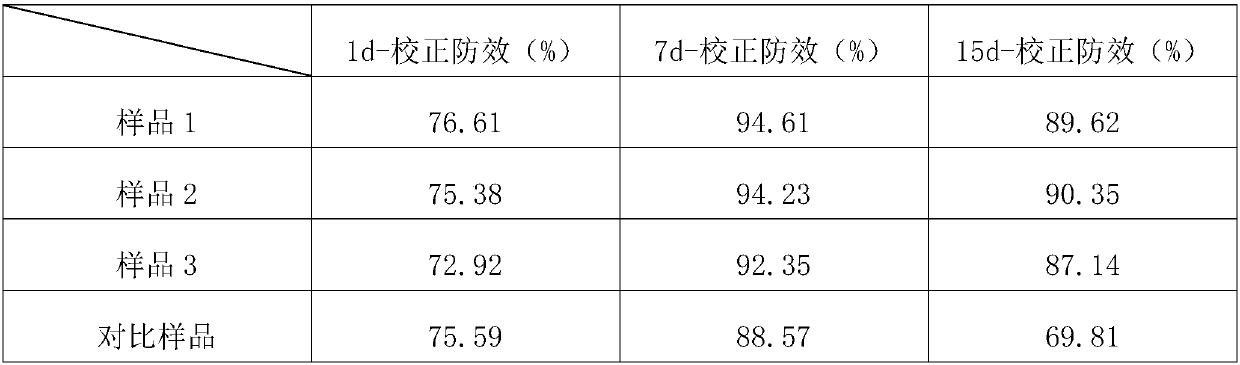

Examples

Embodiment 1

[0020] A preparation method of kumquat red spider insecticidal liquid, comprising the following steps:

[0021] S1. Raw material processing: in parts by weight, take 70 parts of ginkgo testa, 13 parts of calamus, 18 parts of camel cape, and 23 parts of veratrum, wash them, and chop them until the volume is 2 , to obtain the fermentation raw material;

[0022] S2. Cellulose degradation: take the fermentation raw material, add the degradation solution, and carry out the degradation reaction for 7 hours. The temperature of the degradation reaction is 53° C., and the shaking culture is adopted at a shaking speed of 175 rpm to obtain a degradation mixture, wherein the fermentation raw material is The weight ratio to the degradation solution is 7:10;

[0023] S3. Fermentation: Take the degradation mixture, put it into a fermentation container, add the beneficial bacteria agent for fermentation, yeast extract, and sodium chloride agent to mix evenly, keep the temperature at 38°C, and...

Embodiment 2

[0027] A preparation method of kumquat red spider insecticidal liquid, comprising the following steps:

[0028] S1. Raw material processing: in parts by weight, take 60 parts of ginkgo exotesta, 10 parts of calamus, 15 parts of camel cape, and 20 parts of veratrum, wash them, and chop them until the volume is 2 , to obtain the fermentation raw material;

[0029] S2. Cellulose degradation: take the fermentation raw material, add the degradation solution, and perform the degradation reaction for 6 hours. The temperature of the degradation reaction is 50° C., and the vibration culture is adopted at a vibration speed of 165 rpm to obtain a degradation mixture, wherein the fermentation raw material is The weight ratio to the degradation solution is 6:10;

[0030] S3. Fermentation: Take the degradation mixture, put it into a fermentation container, add the beneficial bacteria agent for fermentation, yeast extract, and sodium chloride agent to mix evenly, keep the temperature at 39°C...

Embodiment 3

[0034] A preparation method of kumquat red spider insecticidal liquid, comprising the following steps:

[0035] S1. Raw material processing: in parts by weight, take 80 parts of ginkgo exocarp, 15 parts of calamus, 20 parts of camel cape, and 25 parts of veratrum, wash them, and chop them until the volume is 2 , to obtain the fermentation raw material;

[0036] S2. Cellulose degradation: take the fermentation raw material, add the degradation solution, and perform the degradation reaction for 8 hours. The temperature of the degradation reaction is 55° C., and the vibration culture is adopted at a vibration speed of 185 rpm to obtain a degradation mixture, wherein the fermentation raw material is The weight ratio to the degradation solution is 8:10;

[0037] S3. Fermentation: Take the degradation mixture, put it into a fermentation container, add the beneficial bacteria agent for fermentation, yeast extract, and sodium chloride agent to mix evenly, keep the temperature at 37°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com