Mixed desulfurizing agent prepared from red mud and seawater and flue gas desulfurization method with mixed desulfurizing agent

A desulfurizer, seawater technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as pollution, and achieve the effects of reducing environmental pollution, reducing the cost of desulfurizers, and strengthening desulfurization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

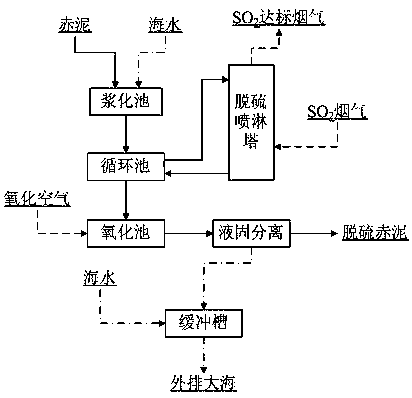

Method used

Image

Examples

Embodiment 1

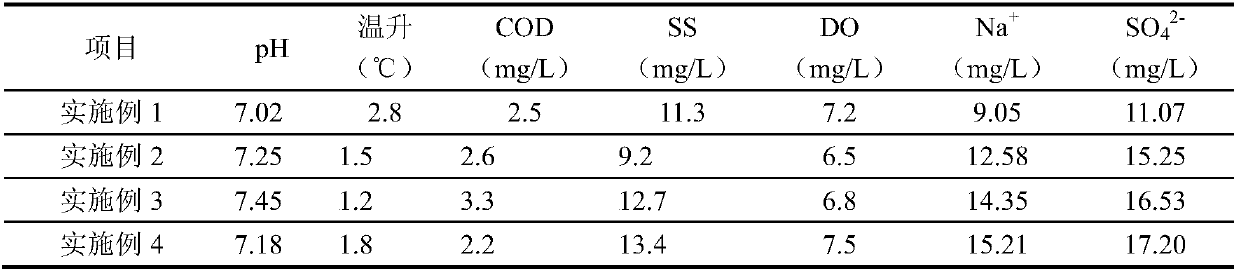

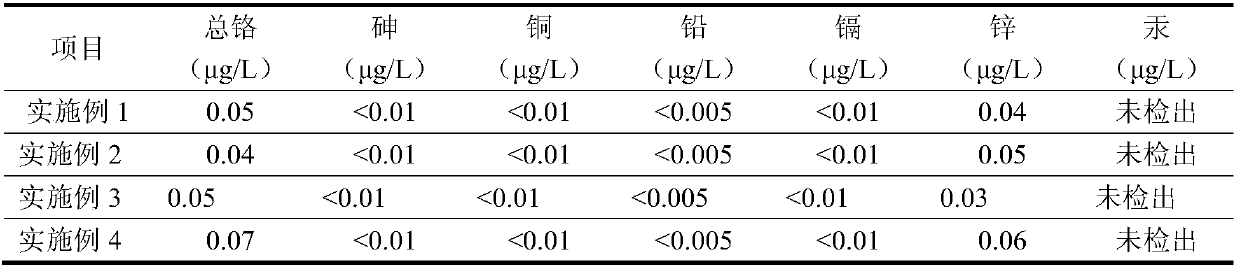

[0026] Red mud and seawater are added to the pulping tank at a mass fraction of red mud (dry basis) of 1.0% to prepare seawater red mud slurry; then transported to the circulation tank, pumped to the desulfurization tower through the desulfurization cycle, and countercurrent contact reaction with the flue gas entering the tower , into the tower flue gas SO 2 The concentration is 500mg / Nm 3 , keep the desulfurization liquid-gas ratio at 6.5L / m 3 , the tower flue gas SO 2 The concentration is 3mg / Nm 3 About; the pH of the seawater red mud slurry in the circulation tank drops to 6.0, discharge 50% of the volume of seawater red mud slurry from the circulation tank, and then replenish the same volume of seawater red mud slurry, the pH of the seawater red mud slurry in the circulation tank rises to 8.10, and continue to desulfurize; The seawater red mud slurry is oxidized in the oxidation tank; after oxidation, it is concentrated in a concentrated sedimentation tank, and the conc...

Embodiment 2

[0029] Red mud and seawater are added to the pulping tank at a mass fraction of red mud (dry basis) of 8% to prepare seawater red mud slurry; then transported to the circulation tank, pumped to the desulfurization tower through the desulfurization cycle, and countercurrent contact reaction with the flue gas entering the tower , into the tower flue gas SO 2 The concentration is 10000mg / Nm 3 , keep the desulfurization liquid-gas ratio at 10.0L / m 3 , the tower flue gas SO 2 The concentration is 22mg / Nm 3 About; the pH of the seawater red mud slurry in the circulation tank drops to 6.0, and 30% of the volume of seawater red mud slurry is discharged from the circulation tank, and then an equal volume of seawater red mud slurry is added, and the pH of the seawater red mud slurry in the circulation tank rises to 8.85, and desulfurization continues; the discharged seawater The red mud slurry is oxidized in the oxidation tank; after oxidation, it is concentrated in a concentrated se...

Embodiment 3

[0032]Red mud and seawater are added to the pulping tank at a mass fraction of red mud (dry basis) of 15% to prepare seawater red mud slurry; then transported to the circulation tank, pumped to the desulfurization tower through the desulfurization cycle, and countercurrent contact reaction with the flue gas entering the tower , into the tower flue gas SO 2 The concentration is 5800mg / Nm 3 , keep the desulfurization liquid-gas ratio at 18.0L / m 3 , the tower flue gas SO 2 The concentration is 5mg / Nm 3 About; the pH of the seawater red mud slurry in the circulation tank drops to 6.0, and 20% of the volume of seawater red mud slurry is discharged from the circulation tank, and then an equal volume of seawater red mud slurry is added, and the pH of the seawater red mud slurry in the circulation tank rises to 8.62, and desulfurization continues; the discharged seawater The red mud slurry enters the oxidation tank for oxidation; after oxidation, it is concentrated in a concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com