CoP/graphene aerogel composite material for high-efficiency hydrogen evolution and preparation method thereof

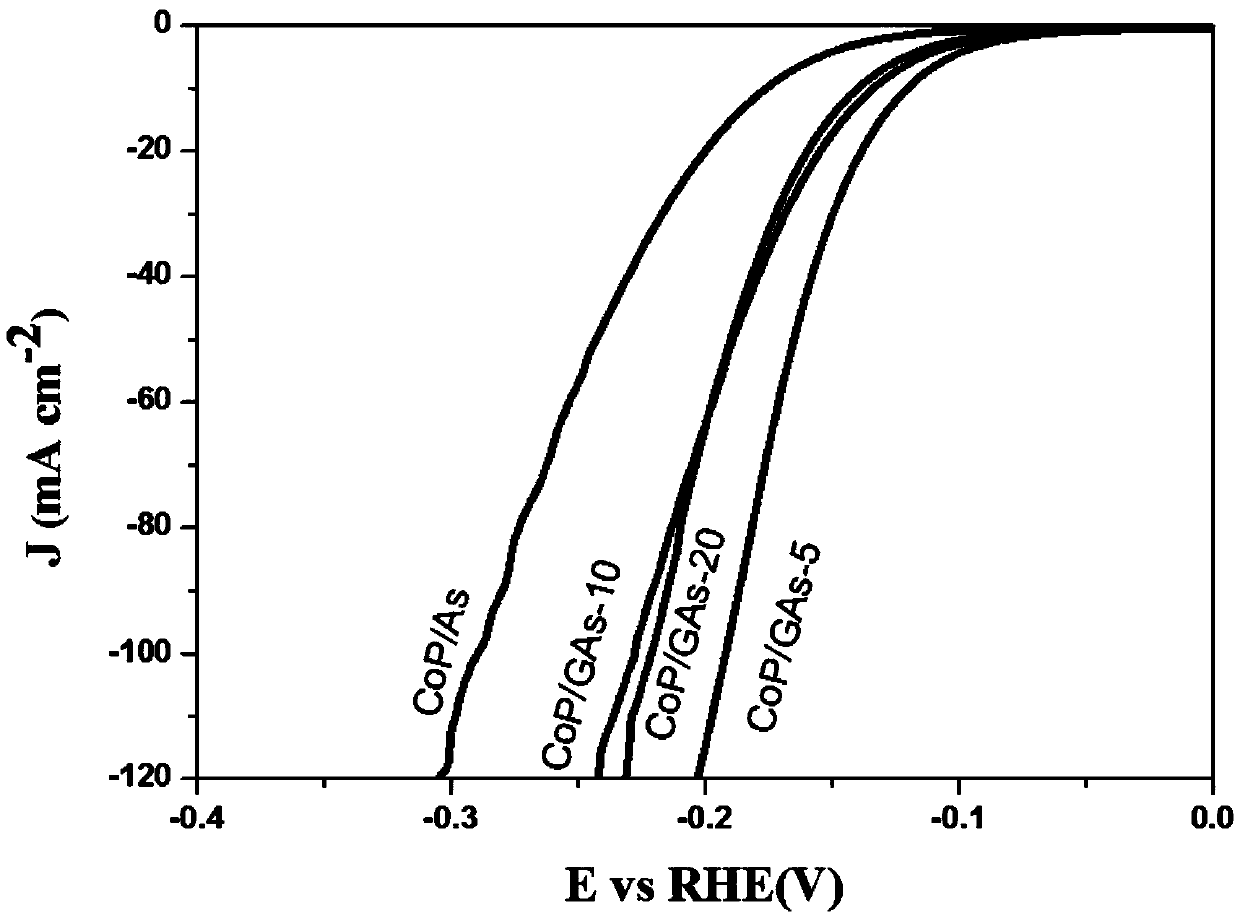

A technology of graphene airgel and composite materials, which is applied in the research field of CoP/graphene airgel high-efficiency hydrogen evolution composite materials and its preparation, and hydrogen evolution performance. It can solve problems such as pollution and electrochemical hydrogen evolution that are rarely reported, and achieve The effect of improving stability, improving the hydrogen evolution performance of electrolyzed water, and having a good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

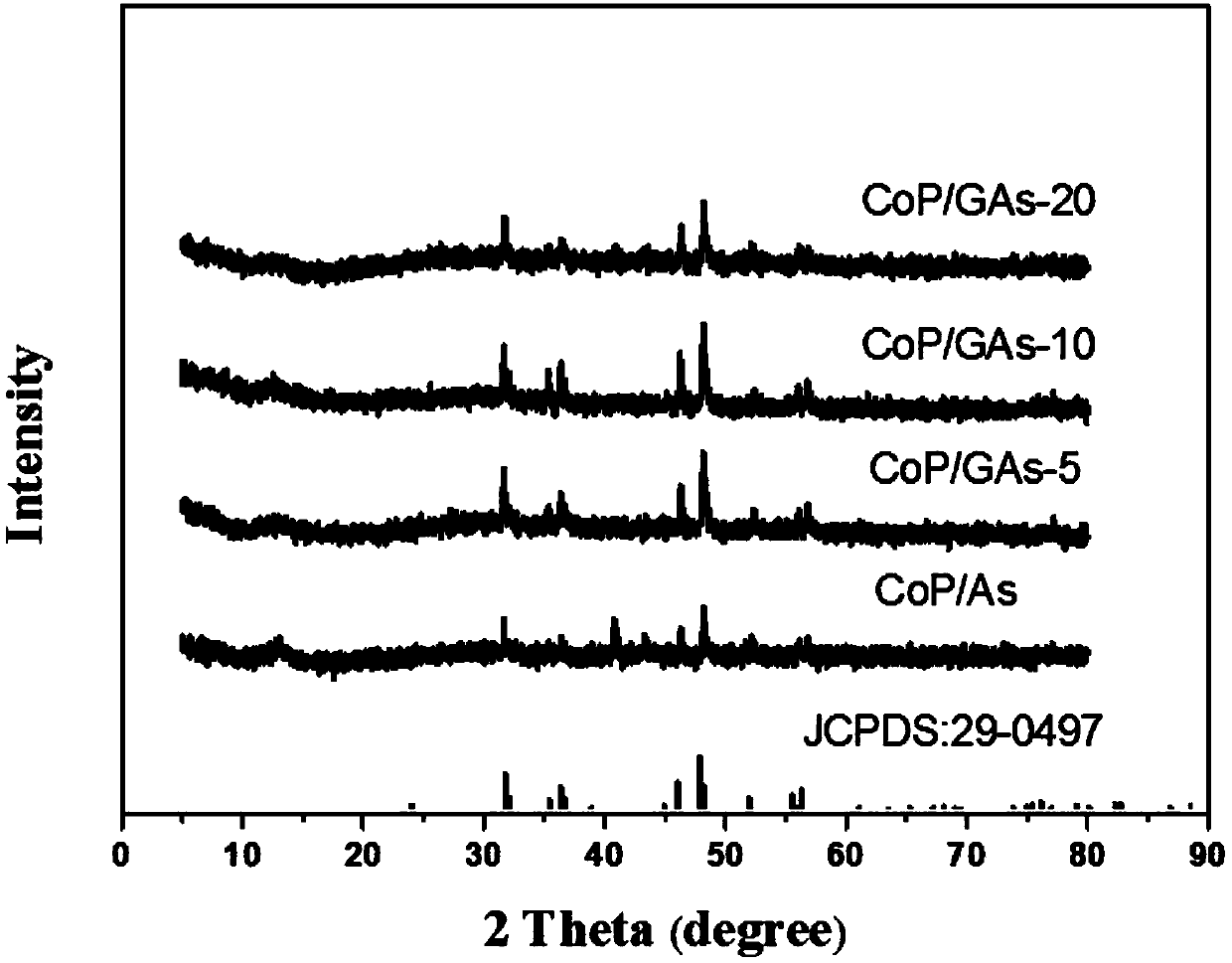

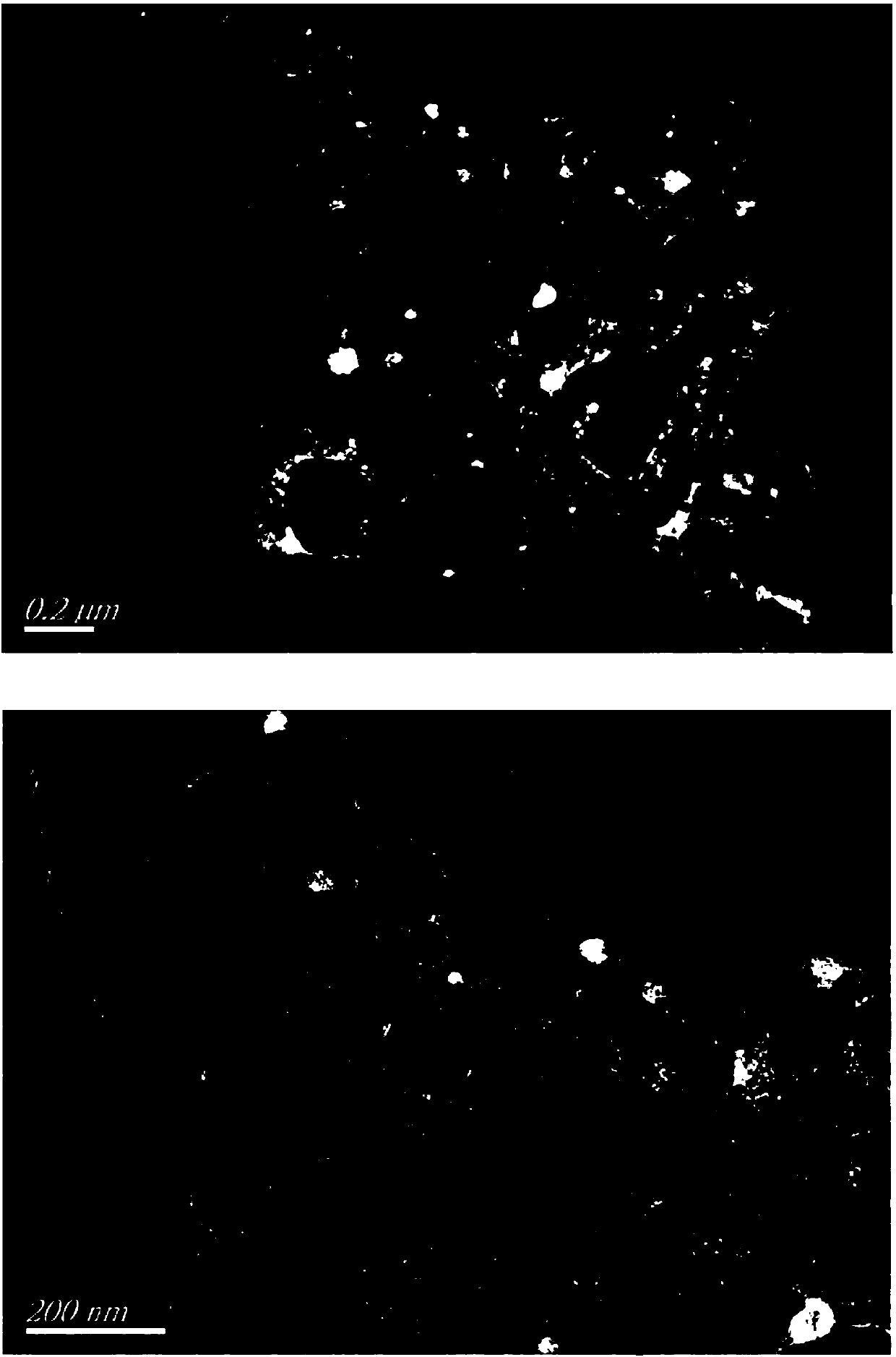

Examples

Embodiment 1

[0026] Preparation of CoP / aerogel (CoP / As) efficient hydrogen evolution composite material

[0027] (1) Weigh Co(NO 3 ) 2 .6H 2 O is dissolved in deionized water and stirred to form 2.5wt% Co(NO 3 ) 2 .6H 2 O solution A.

[0028] (2) Weigh sodium alginate (SA), pour it into deionized water and stir for 12 hours to form a uniform sodium alginate solution B with a mass fraction of 1 wt%.

[0029] (3) Inject 50 ml of solution B into 50 ml of solution A at room temperature to form a hydrogel. The formed hydrogel is aged for 12 hours, and then soaked in deionized water and ethanol for 2 hours each time, and washed 3 times.

[0030] (4) The hydrogel after aging, soaking and washing is freeze-dried in a freeze dryer for 48 hours to form a dry gel.

[0031] (5) Take dry gel and red phosphorus (P) separately, place the red phosphorus at the upstream position of the tube furnace, and place the dry gel at the downstream, perform high-temperature phosphating at a phosphating temperature of 800°C, ...

Embodiment 2

[0033] Preparation of CoP / graphene aerogel high-efficiency hydrogen evolution composite material

[0034] (1) Weigh Co(NO 3 ) 2 .6H 2 O is dissolved in deionized water and stirred to form 2.5wt% Co(NO 3 ) 2 .6H 2 O solution A.

[0035] (2) Weigh sodium alginate (SA), pour it into deionized water and stir for 12 hours to form a uniform sodium alginate solution B with a mass fraction of 1 wt%.

[0036] (3) Measure the GO (2mg / ml) solutions with mass fractions of 5%, 10% and 20% respectively and inject them into solution B, stir, and sonicate in an ultrasonic instrument to obtain dispersion C;

[0037] (4) Inject 50 ml of Dispersion C into 50 ml of Solution A at room temperature to form a hydrogel. The formed hydrogel is aged for 12 hours, and then soaked in deionized water and ethanol 3 times, 2 hours each time, and washed 3 times.

[0038] (5) The hydrogel after aging, soaking and washing is freeze-dried in a freeze dryer for 48 hours until a dry gel is formed.

[0039] (6) Take the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com