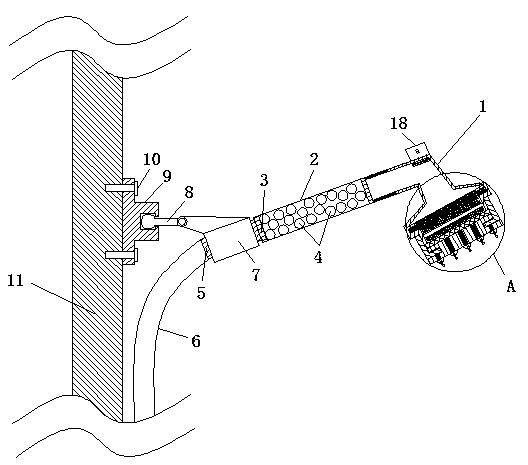

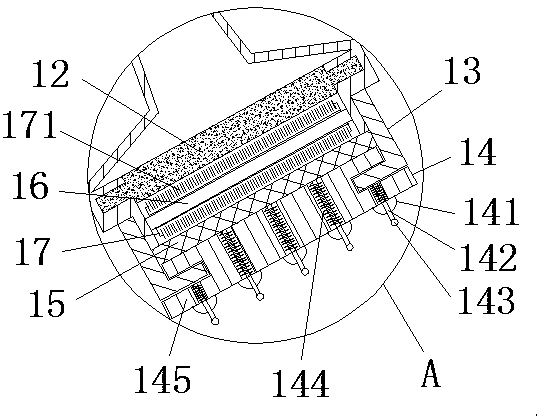

Multifunctional water purifying and filtering sprinkler

A multi-functional, water-purifying technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of not being able to massage the skin surface, not being able to filter bacteria and impurities in the shower, and not having a heating function, etc., to achieve enhanced water quality, good purification effect, and promote The effect of blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a nanocomposite material for softening water, the method comprising the following steps:

[0021] Weigh 18 parts of CaCO 3 / ZSM-5 nanocomposite, 14 parts of active hydroquinone amine resin, 30 parts of bentonite, 10 parts of calcium lignosulfonate, 3 parts of aluminum oxide, and 7 parts of butanediol salicylate were added to the pre- Stir in the mixer, at room temperature, stir at a speed of 1000r / min for 60min, mix thoroughly, add 7 parts of coupling agent KH-560 and 17 parts of triethylene glycol methyl ether in sequence, raise the temperature to 60°C for 2 hours; Separation by filtration through a Schneider funnel, washed twice with 30°C deionized water, dried in an oven at 70°C, and ground to obtain a 1200-mesh nanocomposite.

[0022] The CaCO 3 / ZSM-5 nanocomposite preparation method is as follows:

[0023] Step 1, 0.3kg dry CaCO 3 and 0.1kg of ZSM-5 zeolite powder, activated at 500°C, dispersed in 10L of ethanol, after ball milling, the ...

Embodiment 2

[0033] Weigh 28 parts of CaCO 3 / ZSM-5 nanocomposite, 10 parts of active hydroquinone amine resin, 30 parts of bentonite, 10 parts of calcium lignosulfonate, 3 parts of aluminum oxide, and 7 parts of butanediol salicylate were added to the pre- Stir in the mixer, at room temperature, stir at a speed of 1000r / min for 60min, mix thoroughly, add 7 parts of coupling agent KH-560 and 17 parts of triethylene glycol methyl ether in sequence, raise the temperature to 60°C for 2 hours; Separation by filtration through a Schneider funnel, washed twice with 30°C deionized water, dried in an oven at 70°C, and ground to obtain a 1200-mesh nanocomposite.

[0034] All the other preparations are the same as in Example 1.

Embodiment 3

[0036] Weigh 8 parts of CaCO 3 / ZSM-5 nanocomposite, 18 parts of active hydroquinone amine resin, 30 parts of bentonite, 10 parts of calcium lignosulfonate, 3 parts of aluminum oxide, 7 parts of butanediol salicylate were added to the pre- Stir in the mixer, at room temperature, stir at a speed of 1000r / min for 60min, mix thoroughly, add 7 parts of coupling agent KH-560 and 17 parts of triethylene glycol methyl ether in sequence, raise the temperature to 60°C for 2 hours; Separation by filtration through a Schneider funnel, washed twice with 30°C deionized water, dried in an oven at 70°C, and ground to obtain a 1200-mesh nanocomposite.

[0037] All the other preparations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com