A control method for the pelletizing thrust control system of an air-path hot cutting machine

A thrust control and control method technology, applied in metal processing and other directions, can solve the problems of material particles not meeting higher requirements, low degree of intelligence and automation, and not suitable for large-scale popularization, and achieve novel design and ensure stability. performance, reducing equipment operating power consumption and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments are given below in conjunction with the accompanying drawings, and the technical solutions of the present invention are further described clearly, completely and in detail. This embodiment is the best embodiment based on the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

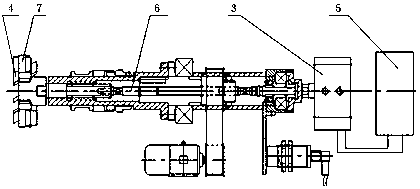

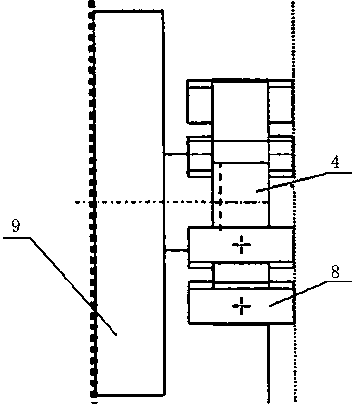

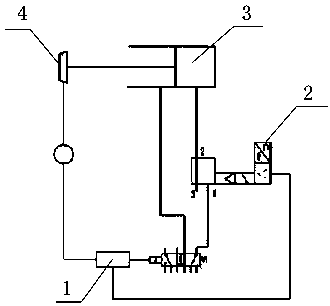

[0030] like Figure 1-3 As shown in the figure, a control method for a pelletizing thrust control system of an air circuit type hot cutter, the control system includes a main control module 1, a proportional control valve 2, a cylinder 3, a cutter head 4 and a dynamometer, the proportional control valve 2. The air cylinder 3, the cutter head 4 and the force measuring instrument are respectively connected with the main control module 1, and the proportional control valve 2 is connected with the air cylinder 3;

[0031] One side of the cylinder 3 is communicated with an air passage box 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com