Electric transmission line grounding down lead suitable for rapid on-site anticorrosion treatment

A technology of grounding down-conductor and anti-corrosion treatment, applied in circuits, electrical components, insulated cables, etc., can solve the problem of no grounding down-conductor corrosion, etc., and achieve the effects of fast curing speed, not easy to age, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

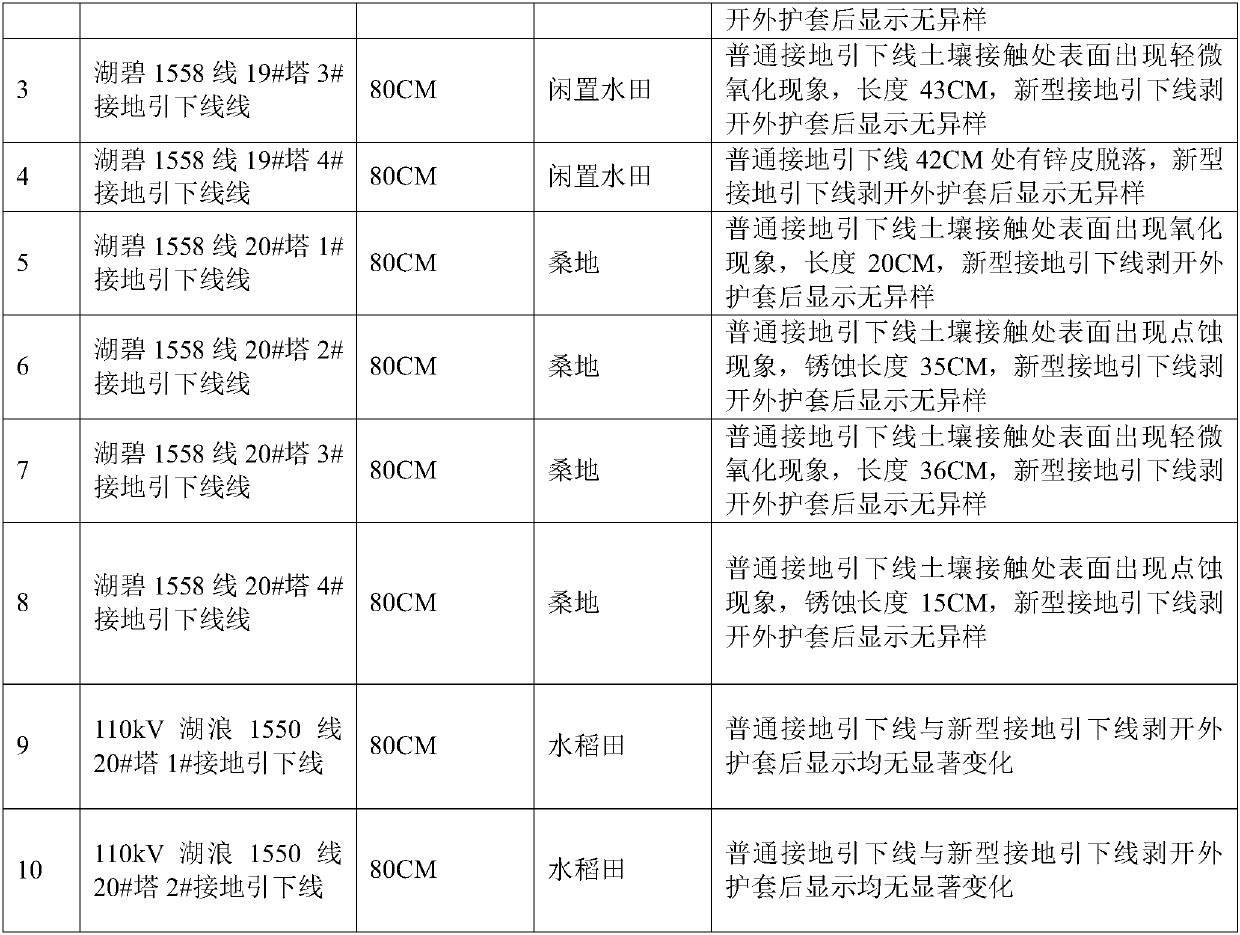

Examples

Embodiment 1

[0034] (1) Corrosion-resistant protection: Pre-corrode the surface of the grounded down-conductor (30cm above the ground and underground after the grounded down-conductor is grounded) with 20wt% dilute hydrochloric acid for 5 minutes, then apply a layer of protective material by electrostatic spraying method, and use ultraviolet light The light source irradiates the protective material for 8 minutes. After curing, a layer of outer sheath is placed on the protective material.

[0035] Wherein, the protective material is composed of the following components by mass: 75 parts of ceramic micropowder, 25 parts of zinc powder, 15 parts of shell micropowder, 3,4-epoxycyclohexylcarboxylate-3',4'-epoxycyclohexyl 25 parts of methyl ester, 8 parts of bis[2-(methacryloyloxy)ethoxy]dimethylsilane, 4 parts of triarylsulfonium hexafluoroantimonate, 8 parts of hyperbranched polyether polyol, 5 parts of polyethylene glycol, 2 parts of p-phenylenediamine, 2 parts of defoamer, 2 parts of disper...

Embodiment 2

[0040](1) Anti-corrosion protection: Pre-corrode 6 minutes with 15wt% dilute hydrochloric acid on the surface of the grounding down conductor (20cm above the ground and underground after the grounding down conductor is grounded), then apply a layer of protective material by electrostatic spraying method, and use ultraviolet The light source irradiates the protective material for 10 minutes. After curing, a layer of outer sheath is placed on the protective material.

[0041] Wherein, the protective material is composed of the following components by mass: 70 parts of ceramic micropowder, 20 parts of zinc powder, 10 parts of shell micropowder, 3,4-epoxycyclohexylcarboxylate-3',4'-epoxycyclohexyl 30 parts of methyl ester, 10 parts of bis[2-(methacryloyloxy)ethoxy]dimethylsilane, 5 parts of triarylsulfonium hexafluoroantimonate, 10 parts of hyperbranched polyether polyol, 6 parts of polyethylene glycol, 1 part of p-phenylenediamine, 1 part of defoamer, 1 part of dispersant, 30 pa...

Embodiment 3

[0046] (1) Anti-corrosion protection: Pre-corrode with 20wt% dilute hydrochloric acid for 4 minutes on the surface of the grounded down conductor (30cm above the ground and underground after the grounded down conductor is grounded), then apply a layer of protective material by electrostatic spraying method, and use ultraviolet The light source irradiates the protective material for 5 minutes. After curing, a layer of outer sheath is placed on the protective material.

[0047] Wherein, the protective material is composed of the following components by mass: 80 parts of ceramic micropowder, 30 parts of zinc powder, 20 parts of shell micropowder, 3,4-epoxycyclohexylcarboxylate-3',4'-epoxycyclohexyl 20 parts of methyl ester, 6 parts of bis[2-(methacryloyloxy)ethoxy]dimethylsilane, 3 parts of triarylsulfonium hexafluoroantimonate, 6 parts of hyperbranched polyether polyol, 4 parts of polyethylene glycol, 3 parts of p-phenylenediamine, 3 parts of defoamer, 3 parts of dispersant, 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com