Cutting resin permeable glass ceramic material for dental restoration and preparation method thereof

A technology of glass ceramics and resin infiltration, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of uneven distribution of ingredients, unsatisfactory cutting performance, etc., and achieve mechanical uniformity, high uniformity, and good cutting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

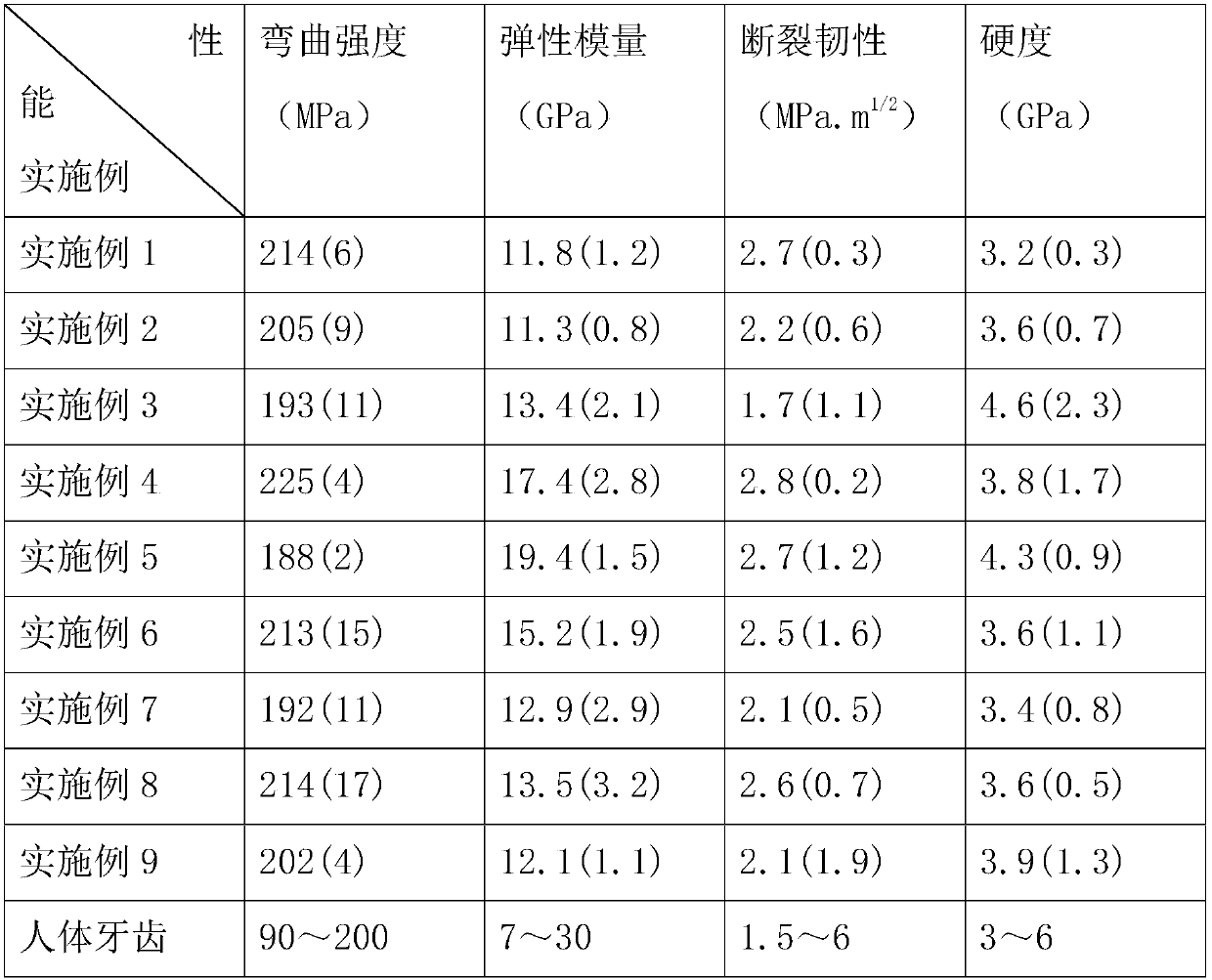

Examples

Embodiment 1

[0029] (1) Preparation of resin system: Stir bisphenol A glycidyl methacrylate and triethylene glycol dimethacrylate for 12 hours in a ratio of 6:4, and then add 0.5% benzyl peroxide Acyl, continue to stir for 12h.

[0030] (2) Preparation of the porous barium glass-ceramic body: Weigh an equal amount of silanized barium glass-ceramic powder with an average particle size of 0.18, 0.4, 0.7 and 1.0 μm in total, 6 g, and rotate in both directions (revolution: 2000 rpm; rotation: 300 rpm ) after mixing evenly, add 2ml of 3% polyvinyl alcohol aqueous solution to infiltrate evenly, place the powder in a 60°C oven to dry, transfer the powder to a steel mold, apply a pressure of 5MPa, and press for 2Min to form a porous barium glass-ceramic body , Porosity 25±5%.

[0031] (3) Resin system permeates the porous barium glass ceramic body: the porous barium glass ceramic body prepared in step (2) is half-immersed in the resin system prepared in step (1), and the whole is placed in a vacu...

Embodiment 2

[0034] (1) Preparation of resin system: Stir bisphenol A glycidyl methacrylate and triethylene glycol dimethacrylate at a ratio of 7:3 for 12 hours and mix well, then add 0.5% benzyl peroxide Acyl, continue to stir for 12h.

[0035] Steps (2)-(4) are the same as steps (2)-(4) in Example 1.

Embodiment 3

[0037] (1) Preparation of resin system: Stir bisphenol A glycidyl methacrylate and triethylene glycol dimethacrylate for 12 hours in a ratio of 3:7, and then add 0.5% benzyl peroxide Acyl, continue to stir for 12h.

[0038] Steps (2)-(4) are the same as steps (2)-(4) in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap