Novel process for making table vinegar by distillers' grains

A technology of brewing vinegar and a new process, which is applied in the field of food processing, can solve the problems of resource waste, long process cycle, and large waste of use, and achieve the effects of reducing pollution, reducing production costs, and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

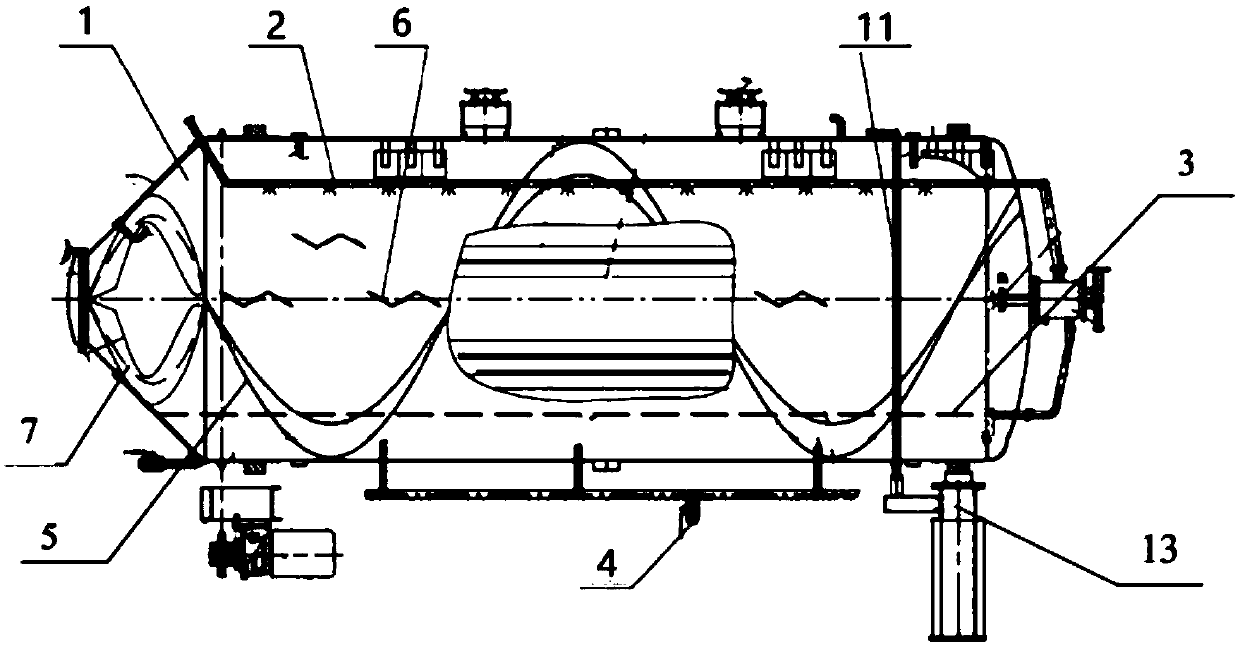

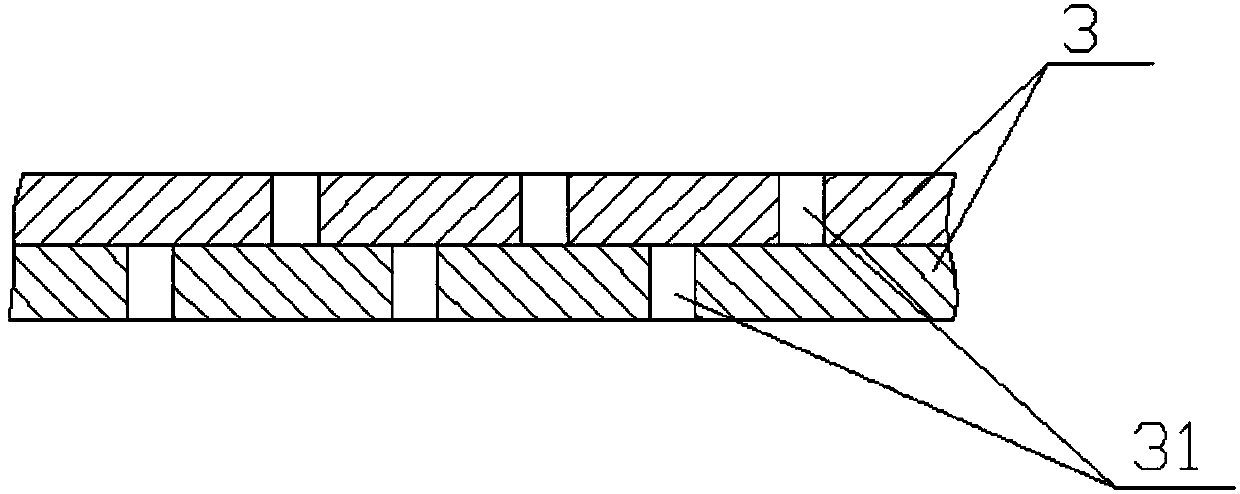

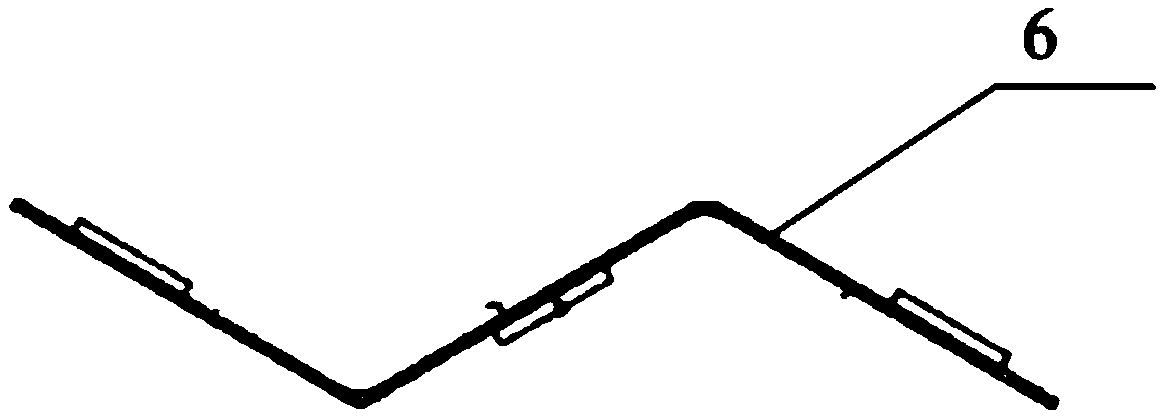

Image

Examples

Embodiment 1

[0041] Specifically include the following steps:

[0042] 1. Pre-treatment of distiller's grains

[0043] 1. Prepare acetic acid bacteria culture solution, add 0.05-0.1% Chinese Academy of Sciences 1.41 ie Shanghai brewing 1.01 acetic acid bacteria in water, temperature 32-35°C, pH 4.0-6.0, mix well.

[0044] 2. Prepare a fermented liquid, which is a fermented liquid formed by mixing tail wine, yellow water and acetic acid bacteria culture liquid according to the ratio of 10-13:0.8-1.2:1.5-2 by weight. In this embodiment, 120kg of tail wine, 10kg of yellow water and 17kg of acetic acid bacteria culture solution were stirred in a stirring tank as a fermentation broth for subsequent use.

[0045] 3. Adjust the water content, add slurry water to the distiller's grains and cool it, so that the water content in the distiller's grains is 50-60%.

[0046] 4. Prepare fermented grains, add bran, fermented unstrained grains seeds and fermentation liquid to the distiller's grains after...

Embodiment 2

[0070] Specifically include the following steps:

[0071] 1. Pre-treatment of distiller's grains

[0072] 1. Adjust the water content, add slurry water to the distiller's grains and cool it, so that the water content in the distiller's grains is 50-60%.

[0073] 2. Secondary fermentation of distiller's grains, adding koji powder and yeast to the distiller's grains for alcoholic fermentation, wherein the distiller's grains, koji powder and yeast are mixed according to the weight ratio of 10-15:0.8-1.5:0.08-0.15 to prepare the brewing unstrained spirits , then alcoholic fermentation 8-10 days, obtained vinegar material; The present embodiment gets distiller's grains 400kg, koji powder 30kg, yeast 4kg and mixes and ferments 9 days, obtains vinegar material.

[0074]3. Prepare acetic acid bacteria culture solution, add 0.05-0.1% Chinese Academy of Sciences 1.41 acetic acid bacteria and 10% fire fermented grains seeds (the fermented grains on the fourth day when the last fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap