An engine with a water injection system

A technology of water spray system and engine, which is applied in the direction of engine components, engine cooling, machine/engine, etc. It can solve the problems of spark plug cooling difficulty, pre-combustion chamber cooling difficulty, and low feasibility, so as to ensure durability and low The failure rate and the effect of reducing the frequency of water addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

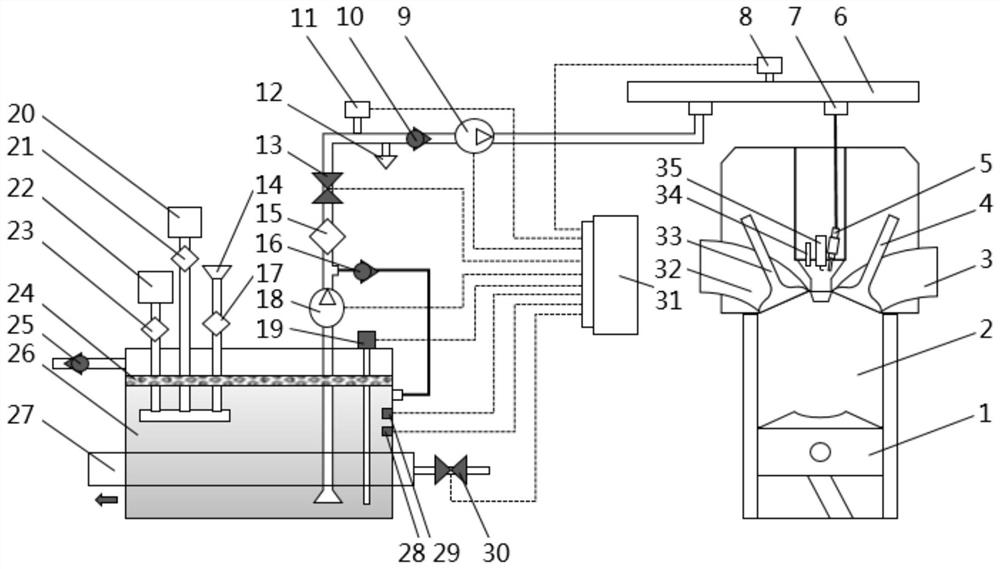

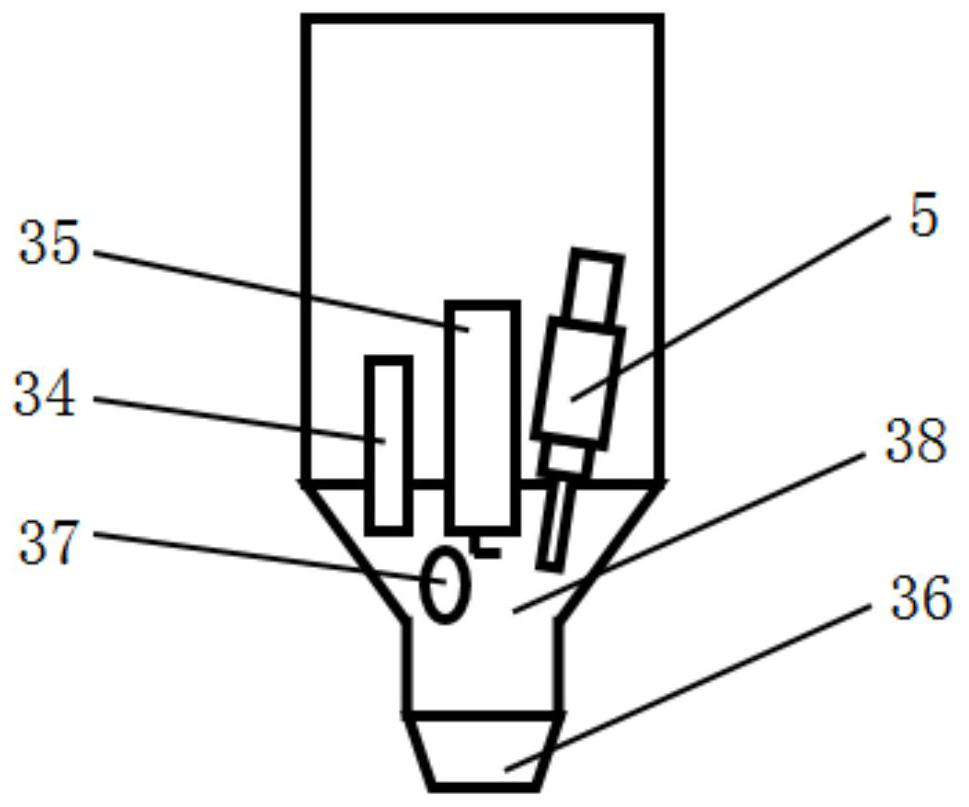

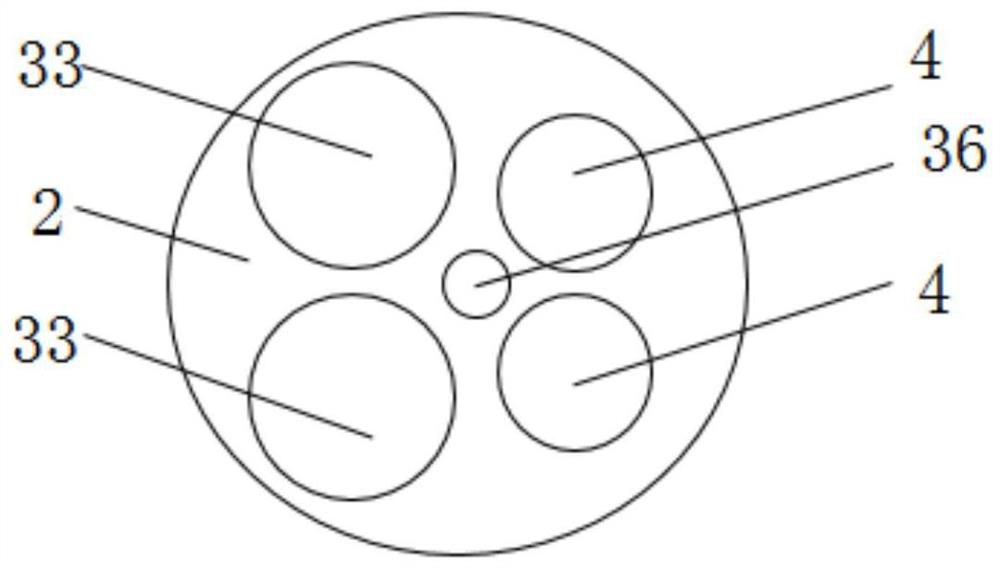

[0036] see Figure 1-3 . As shown in the figure, the present invention discloses an engine with a water injection system, including a main combustion chamber 2, a pre-combustion chamber 38 and a water injection system, and the main combustion chamber 2 is connected with the pre-combustion chamber 38 through a nozzle 36 In general, the pre-combustion chamber 38 is provided with a first intake port 37 , an injector 34 and a spark plug 35 , and the first intake port 37 is used for introducing a mixture gas with a higher concentration.

[0037]The water spray system includes a water supply device, a spray device and an electronic control unit 31, and the water supply device communicates with the spray device through a water pipe; the water supply device includes a water storage tank 26, a second water pump 18 and an accumulator 11. The second water pump 18 and the accumulator 11 are sequentially arranged along the water pipe, the water inlet and the water outlet of the second wat...

Embodiment 2

[0044] The invention discloses an engine with a water injection system, including a main combustion chamber 2, a pre-combustion chamber 38 and a water spray system, the main combustion chamber 2 communicates with the pre-combustion chamber 38 through a nozzle 36, the pre-combustion chamber The combustion chamber 38 is provided with a first intake port 37 , a fuel injector 34 and a spark plug 35 , and the first intake port 37 is used for introducing a mixed gas with a higher concentration.

[0045] The water spray system includes a water supply device, a spray device and an electronic control unit 31, and the water supply device communicates with the spray device through a water pipe; the water supply device includes a water storage tank 26, a second water pump 18 and an accumulator 11. The second water pump 18 and the accumulator 11 are sequentially arranged along the water pipe, the water inlet and the water outlet of the second water pump 18 communicate with the water pipe re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com