A single-board dual-channel ft mass production test and yield analysis system and method

An analysis system, dual-channel technology, applied in the field of systems, can solve the problems of inaccurate formulation of yield control lines, high test costs, and increased difficulty in maintainability, so as to facilitate analysis and problem handling, and improve test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

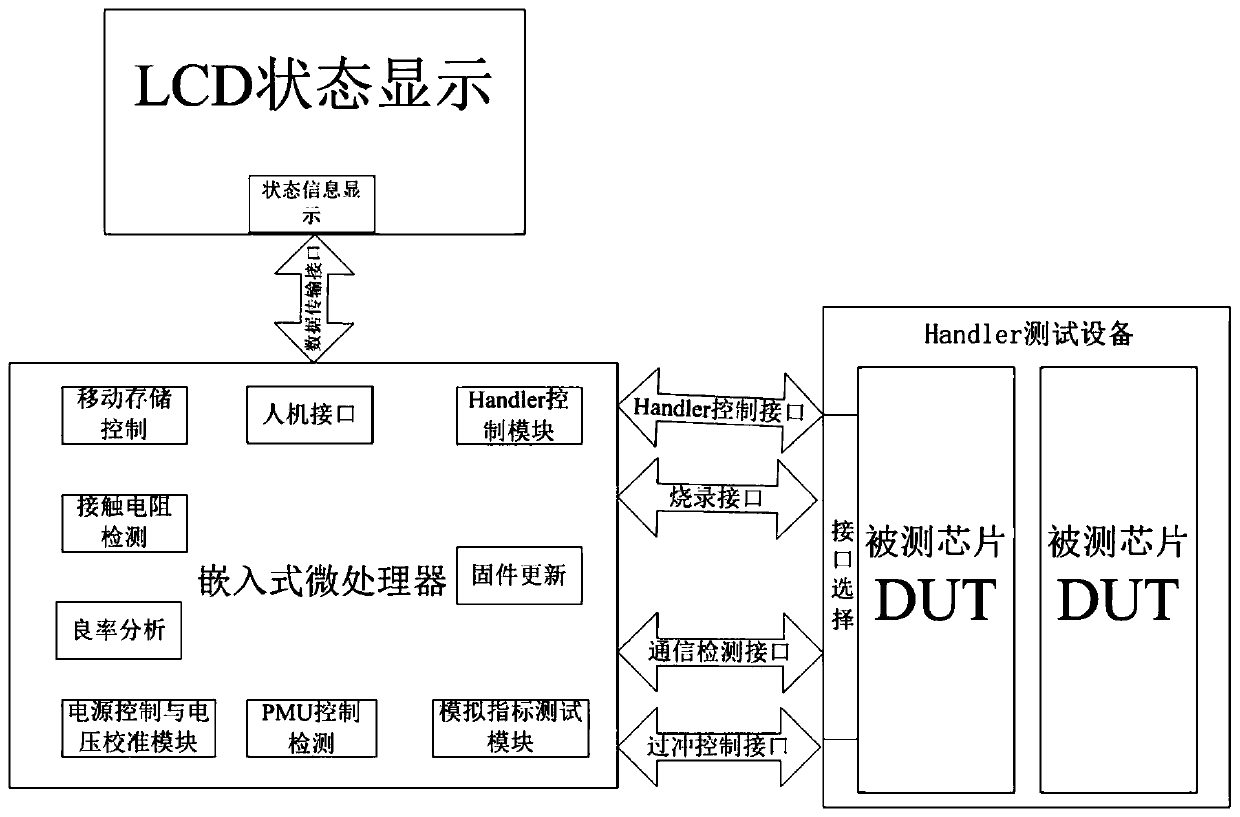

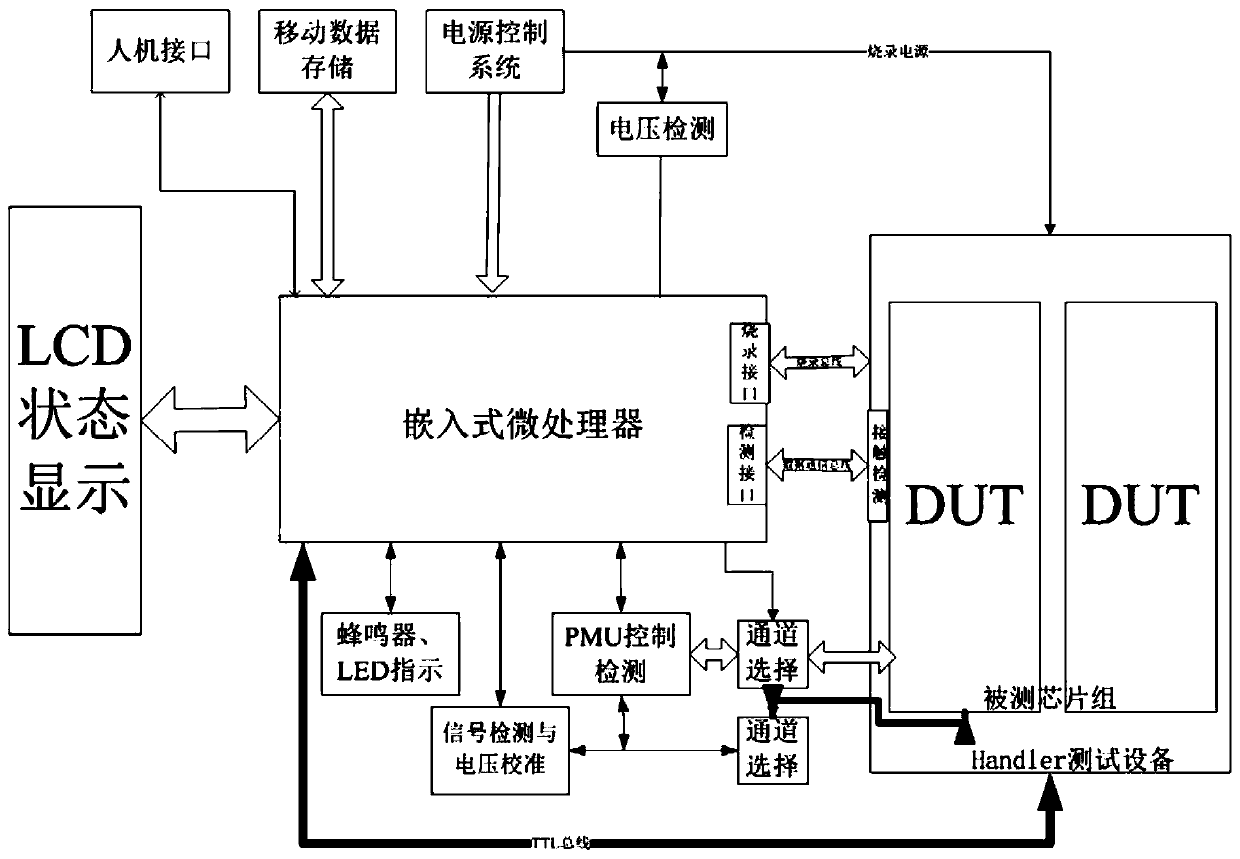

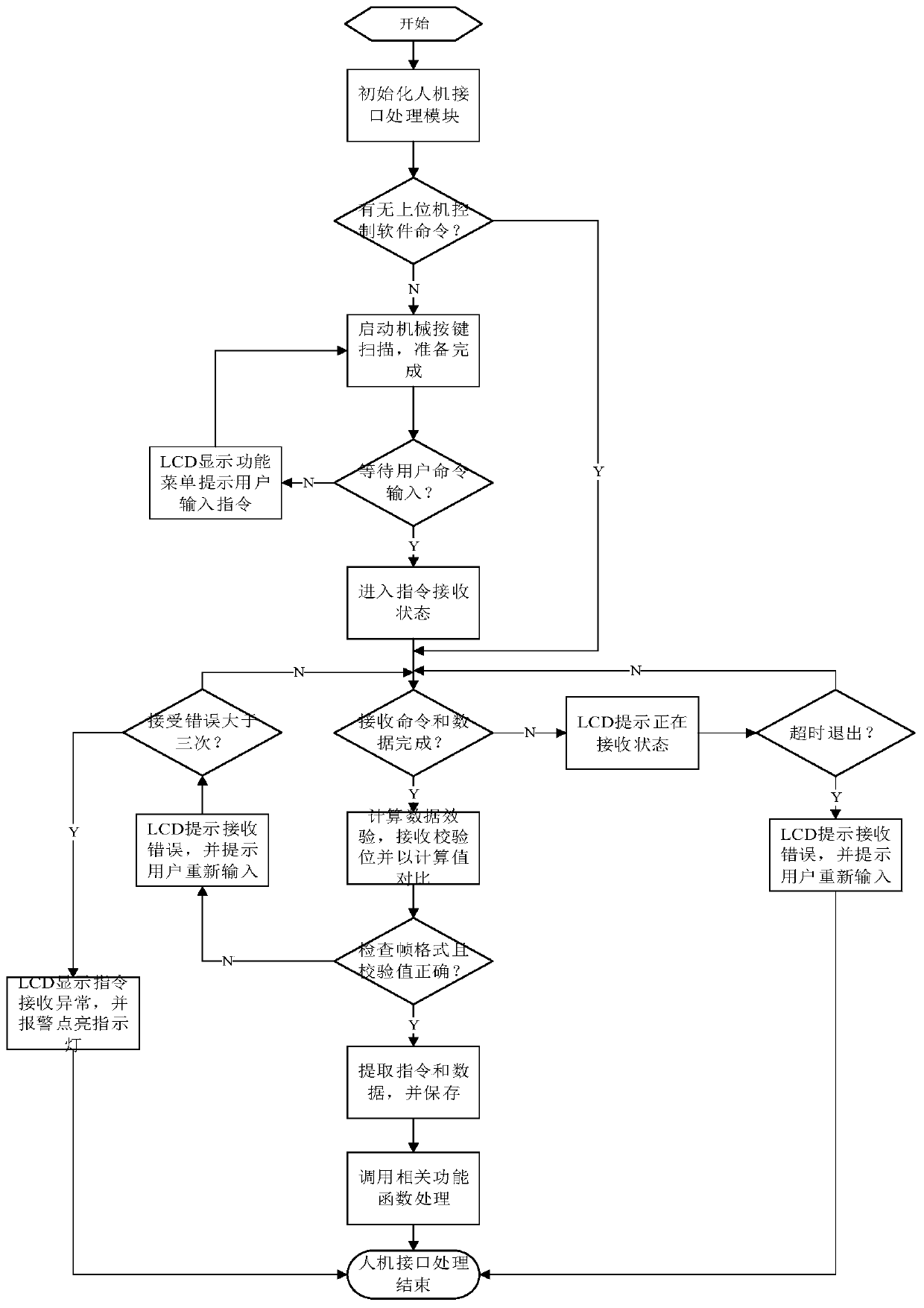

[0047] figure 1 , figure 2 As shown, the single-board dual-channel FT mass production test and yield analysis system realized by the present invention is characterized in that the system can perform batch automated multi-simulation parameter index test on the chip during the FT mass production stage and provides the necessary means. Multi-index item test methods are integrated in a system for testing and yield processing, including contact resistance testing, which greatly improves testing efficiency, and performs preprocessing and display according to related issues, and stores the tested ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com