A composite treatment method for radioactive waste oil

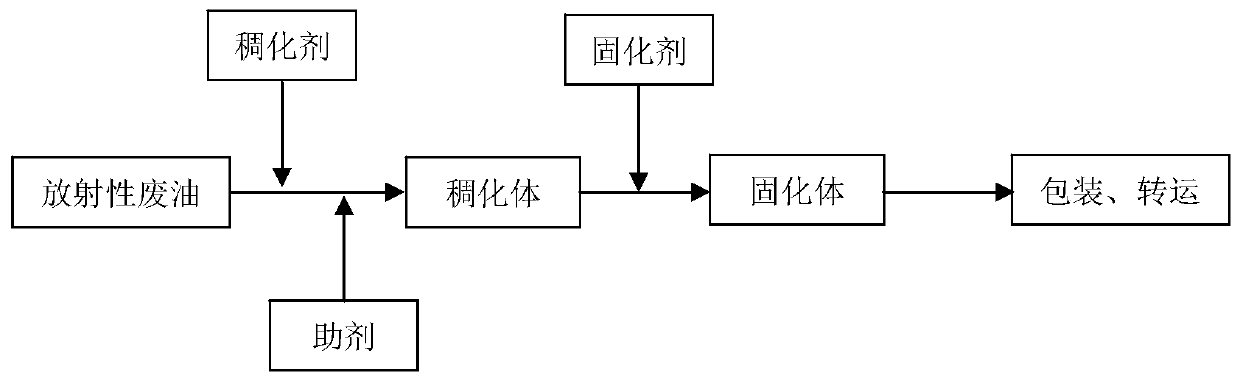

A composite treatment and radioactive technology, applied in radioactive purification, nuclear engineering and other directions, can solve the problems of high difficulty and high cost of environmental pollution control, local environmental pollution, difficulty and high cost of radioactive organic waste oil, and achieve easy collection and reduce seepage. The effect of oil rate, excellent strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The inventors found that the thickener can disperse in the waste oil and form a structural framework, and make the waste oil be absorbed and fixed in the structural framework, thereby forming a plastic semi-solid lubricating grease. Thus, the present inventors examined the thickening effect on waste pump oil of the following substances, which may have a thickening effect: paraffin wax, stearic acid, sepiolite, sericite, and organobentonite.

[0055] Test 1#: Turbine oil 85g, add organic bentonite (consumption is 25wt%, promptly account for 25wt% of the quality of the oil product to be treated, for example, 100g of waste oil to be treated, add 25g of organic bentonite, the same below), stir at room temperature Evenly, then add a small amount of ethanol (5ml), continue stirring to obtain a sample, and take a sample for oil leakage test;

[0056] Test 2#: Turbine oil 85g, add organic bentonite (consumption is 30wt%), stir evenly at room temperature, then add a small amount...

Embodiment 2

[0064] Several groups of samples using organic bentonite as the thickener were tested for oil seepage rate, and the test 1#, 4# and 6# samples in Example 1 were selected and placed on 10 layers of filter paper respectively, and observed and recorded after 12 hours. The size of the mimeograph and the number of layers of oil seepage, the test results are as follows image 3 Shown: With the gradual increase of the amount of organic bentonite, the number of sheets and wetted area of filter paper wetted by the treated oil gradually decreased.

[0065] The results of the turbine oil thickening test of comprehensive embodiment 1 and 2 can be known: sepiolite and sericite have no obvious thickening effect to turbine oil; Notable thickening effect. According to the test phenomenon, the advantages and disadvantages of the three thickeners are listed in Table 4.

[0066] Table 4 Comparison of advantages and disadvantages of three thickeners

[0067] Advantages of thickener ...

Embodiment 3

[0070] Organic bentonite is used to thicken turbine oil. Although the oil seepage rate after thickening is low, it still cannot meet the requirement of less than 1% oil seepage rate. In view of this, the inventor continues to add an appropriate amount of curing agent on the basis of the thickened oil. Ideally, the selected curing agent should have a stronger oil retention and oil fixation effect, so as to reduce the oil leakage rate of the thickened oil to a greater extent.

[0071]In this example, polyurea was selected as the curing agent, and 100 g of X46 turbine oil was used to compare and analyze the curing effects of three polyureas Q4, Q2 and S2 on turbine oil through the following three sets of experiments. Test 1#: 10g Q4; Test 2#: 10g Q2; Test 3#: 10g S2. After adding polyurea, stir evenly at room temperature, and take samples for observation. Depend on Figure 4 It can be seen that the curing effects of Q4 and Q2 on turbine oil are similar. The cured turbine oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com