Method for producing cherry vinegar by utilizing cherry wine lees

A cherry wine and cherry technology, applied in the field of cherry vinegar production, can solve the problems of difficult control of cherry vinegar quality, high cost of raw materials, low fragrance, etc., achieve high efficiency and low cost production of functional ingredients, short production cycle, and promote the production of aromatic esters The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

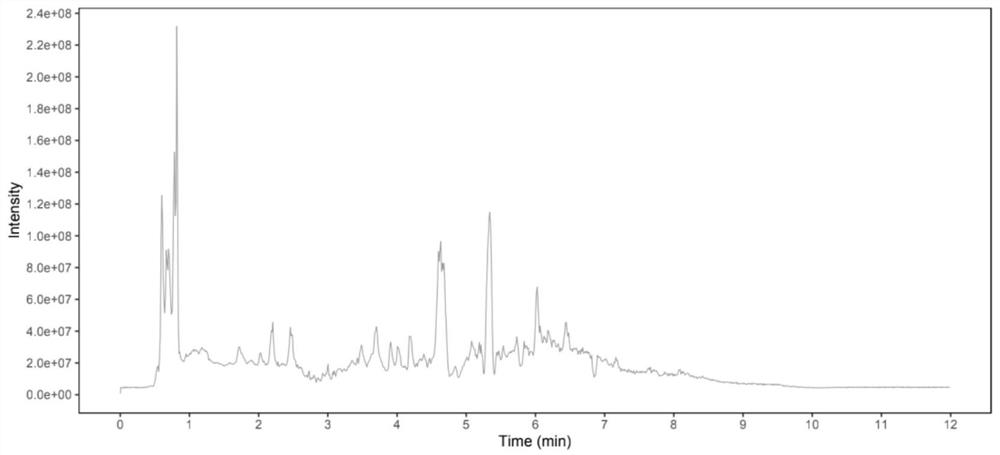

Image

Examples

Embodiment 1

[0035]Take freshly brewed naturally precipitated cherry lees to prepare 100mL of fermented liquid, in which the content of cherry lees is 30FWT g / L, the content of glucose is 3g / L, the content of yeast powder is 5g / L, the content of magnesium sulfate is 0.6g / L, and the content of potassium dihydrogen phosphate 0.3g / L, calcium chloride content 140mg / L, ammonium hydrogen phosphate content 0.3g / L, ferrous sulfate heptahydrate content 0.3mg / L, sugar content adjusted to 13°Brix with glucose, pasteurized at 65°C for 30min Then use the cherry wine after clarification to adjust the alcohol content of the fermented liquid to make its alcohol concentration to 8 degrees, insert the acetic acid bacteria AS1.41 after the expansion, the addition is 9wt%, and adjust the pH value with 1% citric acid solution To 3.5, under the condition of 30 ℃, after cultivating in a constant temperature incubator with a rotating speed of 180r / min for 6 days, the fermented liquid was pasteurized for 30 minutes...

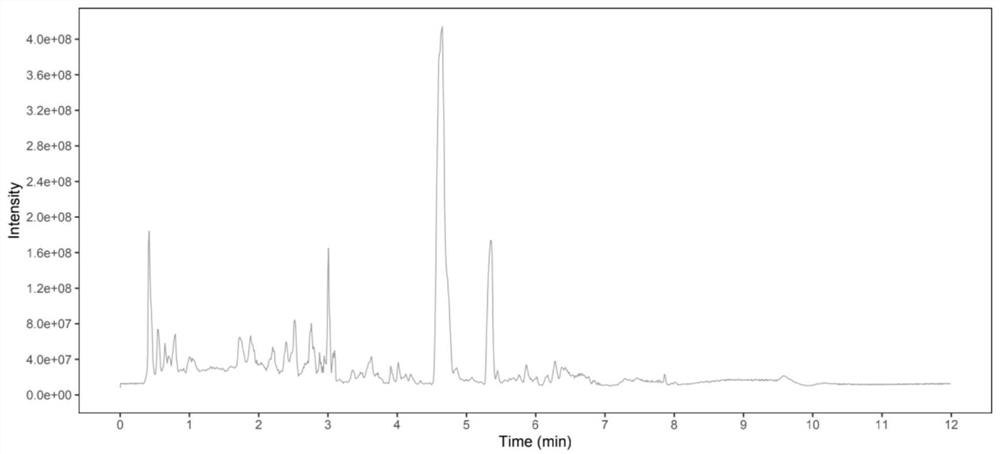

Embodiment 2

[0037] Take freshly brewed naturally precipitated cherry lees to configure 100mL of fermentation broth, in which the content of cherry lees is 30FWTg / L, the content of glucose is 3g / L, the content of yeast powder is 5g / L, the content of magnesium sulfate is 0.6g / L, and the content of potassium dihydrogen phosphate is 0.3 g / L, the content of calcium chloride is 140mg / L, the content of ammonium hydrogen phosphate is 0.3g / L, the content of ferrous sulfate heptahydrate is 0.3mg / L, the sugar content is adjusted to 13°Brix with glucose, and pasteurized at 65°C for 30min; Then use the cherry wine after clarification to adjust the alcoholicity of the fermented liquid to make its alcohol concentration to 8 degrees, add 10g / L of the crude polysaccharide extract of cherry pomace, and add cellulase and pectinase with a mass ratio of 8:1:1 , Protease compound enzyme liquid, the addition amount is 60mg / L, inserts the Acetobacter Frings 30029050 or the acetic acid bacteria AS1.41 after expand...

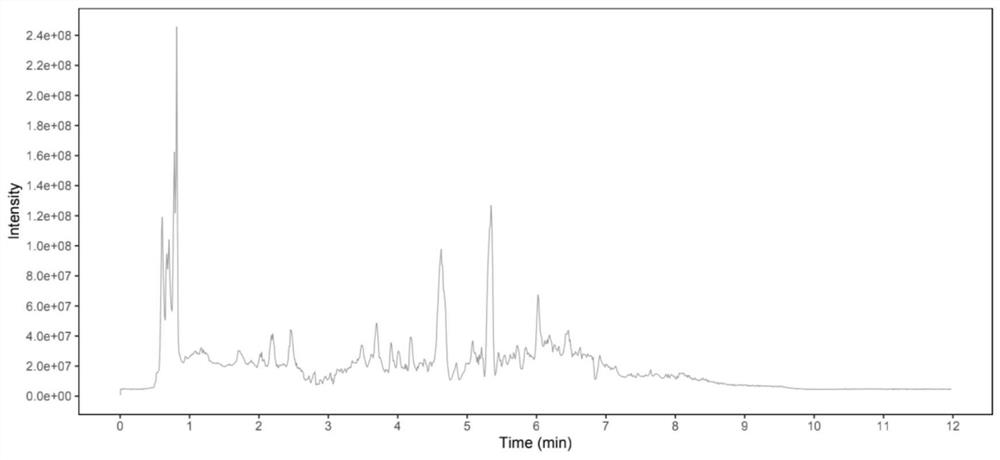

Embodiment 3

[0039] Take freshly brewed naturally precipitated cherry lees to configure 100mL of fermentation broth, in which the content of cherry lees is 30FWTg / L, the content of glucose is 3g / L, the content of yeast powder is 5g / L, the content of magnesium sulfate is 0.6g / L, and the content of potassium dihydrogen phosphate is 0.3 g / L, the content of calcium chloride is 140mg / L, the content of ammonium hydrogen phosphate is 0.3g / L, the content of ferrous sulfate heptahydrate is 0.3mg / L, the sugar content is adjusted to 13°Brix with glucose, and pasteurized at 65°C for 30min; Then use the cherry wine after clarification to adjust the alcoholicity of the fermented liquid to make its alcohol concentration to 8 degrees, add 10g / L of the crude polysaccharide extract of cherry pomace, and add cellulase and pectinase with a mass ratio of 8:1:1 1. Protease compound enzyme solution, the addition amount is 60mg / L, add 50mg / L disodium nucleotide, insert the expanded Acetobacter Frings 30029050 or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com