Method for improving electrolyte injecting efficiency of lithium ion battery

A lithium-ion battery and electrolyte technology, which is used in battery pack parts, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc., can solve the problems of bad ratio, difficulty in filling liquid, and low efficiency of electrolysis, so as to improve production capacity and improve Production process, the effect of improving the production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

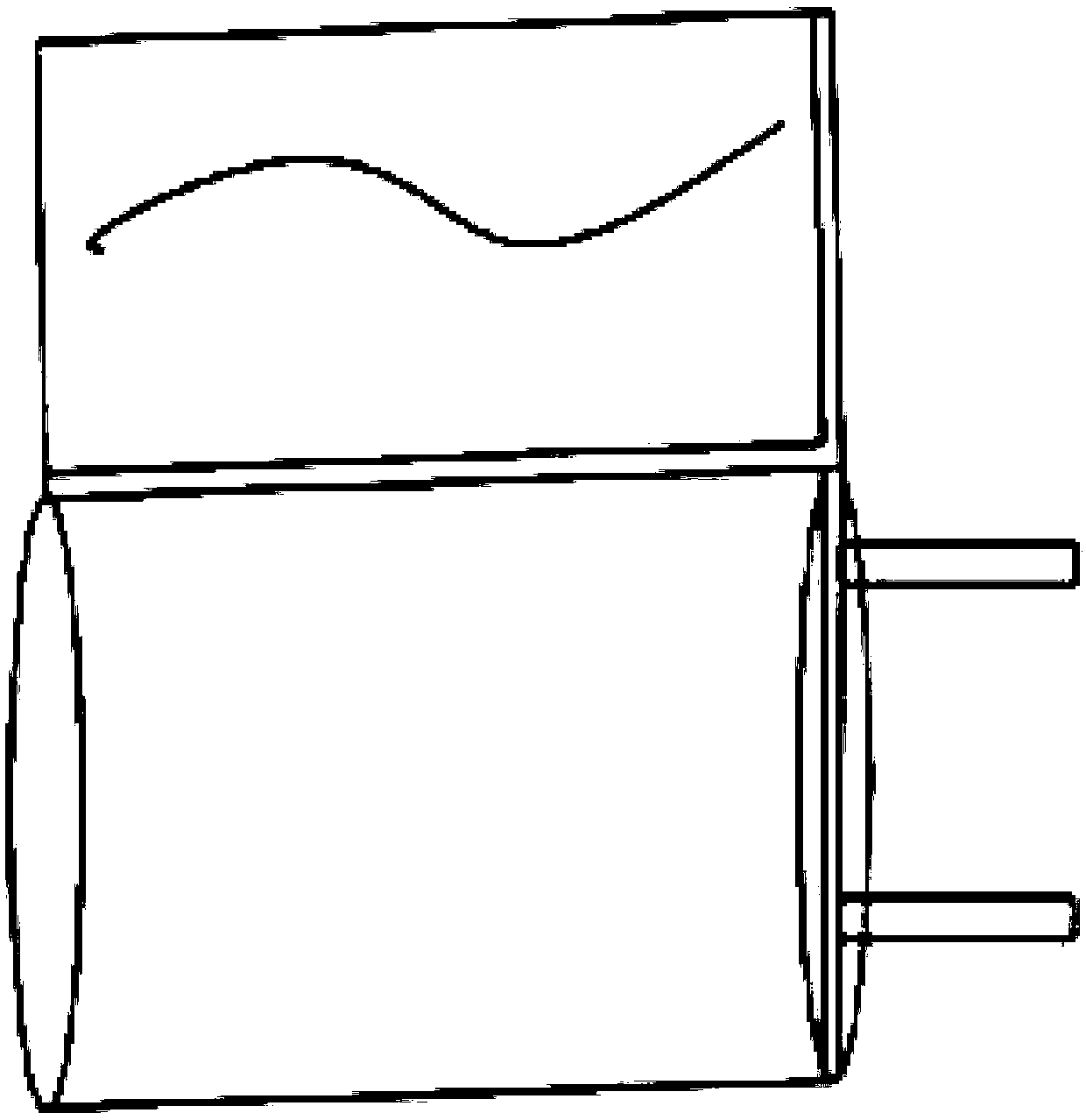

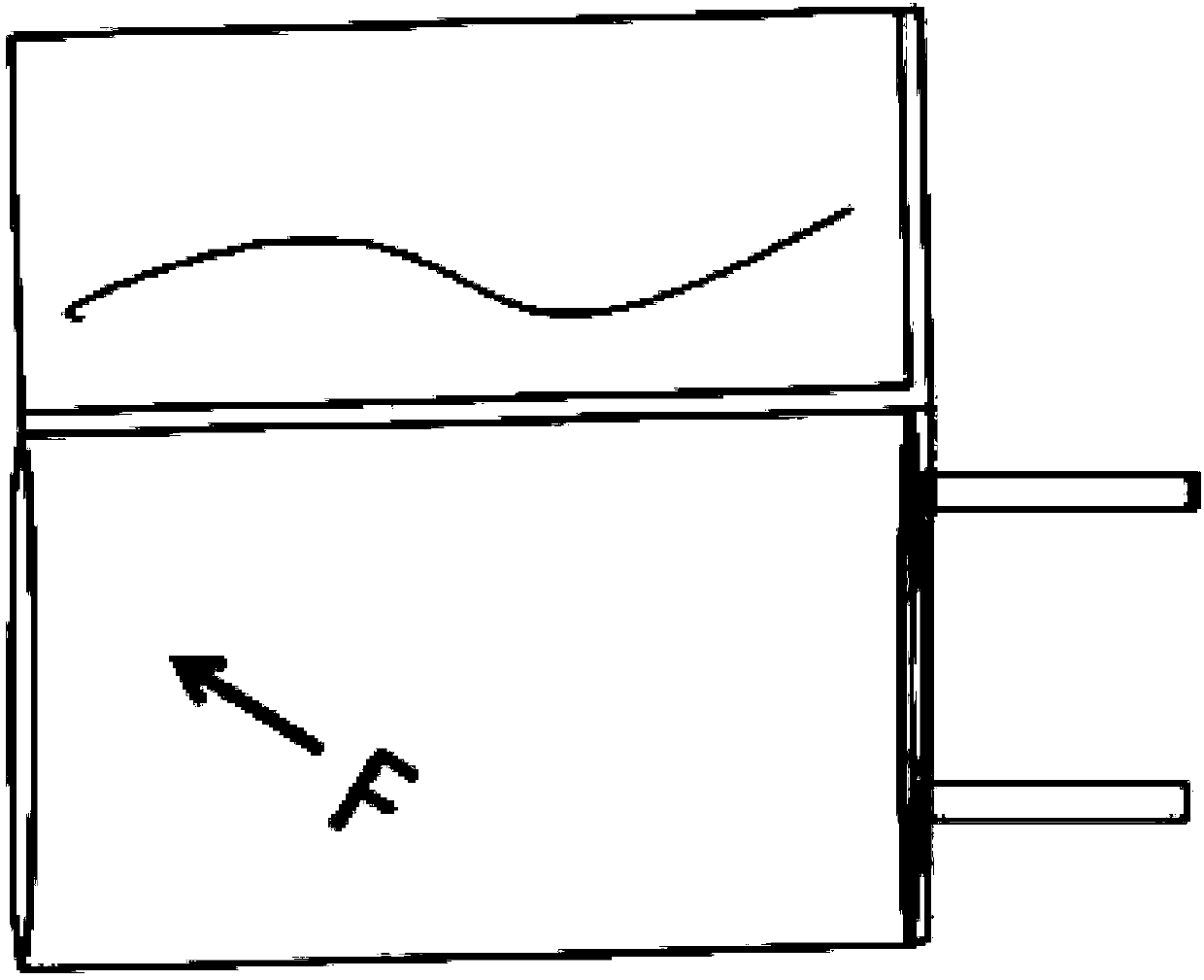

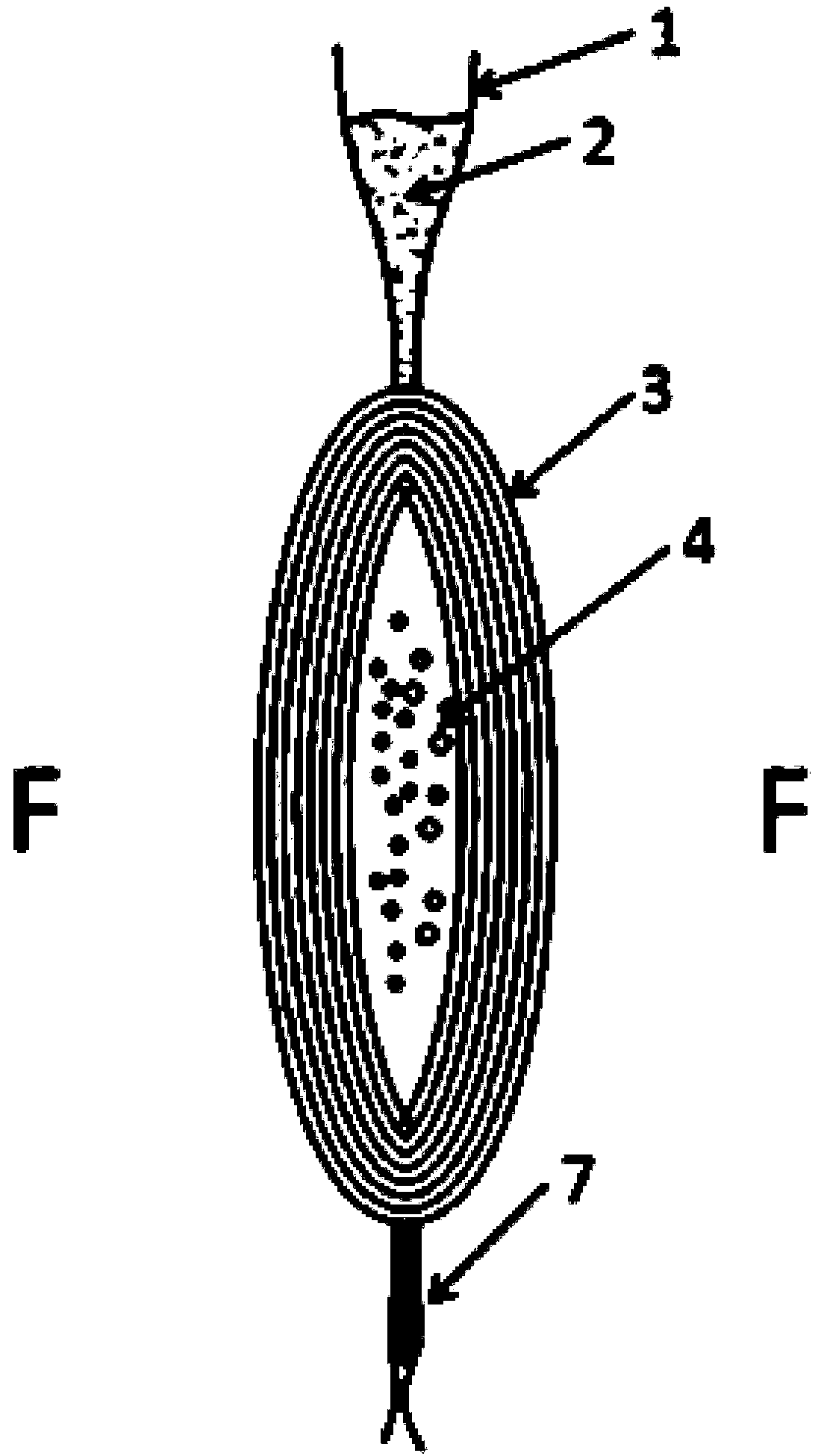

[0026] Such as Figure 2-4 As shown, the present invention provides a method for improving the electrolyte injection efficiency of a lithium-ion battery. The method is to apply a pressure F to the outside of the lithium-ion battery winding core 5 by using a pressure device, and use the method of forming a relative vacuum inside the battery winding core 5 Filling the electrolyte; specifically includes: before injecting the liquid, apply a certain pressure F to the battery core 5 with a pressure device to clamp the battery core 5, so that the air 6 inside the battery core is discharged; and then in the battery air bag 1 Inject the electrolyte 2; after the injection of the electrolyte 2 is completed, the pressure of the battery core 5 is released, and the battery core 5 expands outward according to its own elasticity, releasing a certain space, and a relative vacuum is formed inside the battery core 5; in a relative vacuum Under the action of the suction force, the electrolyte so...

Embodiment 2

[0028] Such as Figure 5 As shown, a pressure device used in a method for improving the electrolyte injection efficiency of lithium-ion batteries of the present invention includes a base 12, a fixed plate 11 and a thrust device, and the thrust device includes a compression cylinder 10 and The thrust plate 8 connected to the compression cylinder 10; the fixed plate 11 is vertically and longitudinally arranged on one side of the base 12; the fixed plate 11 and the thrust plate 8 are arranged opposite; the fixed plate 11 is provided with a battery toward the inside of the thrust plate 8 Shelf 9; the battery shelf 9 is fixed on the fixed plate 11 with bolts, which is convenient for adjustment according to the type of the battery.

[0029] When the electrolyte is injected, the battery is first placed between the fixed plate 11 of the pressure device and the thrust device, placed on the battery shelf 9, and adjusted so that the battery winding core 5 is in a suitable position, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com