Optical F-P resonant cavity for frequency stabilization of semiconductor laser

A laser and semiconductor technology, applied in semiconductor lasers, optical resonator structures, lasers, etc., can solve the problems of difficult laser frequency pullback, lack of universality, and high process complexity, achieving simple structure and simple assembly. , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

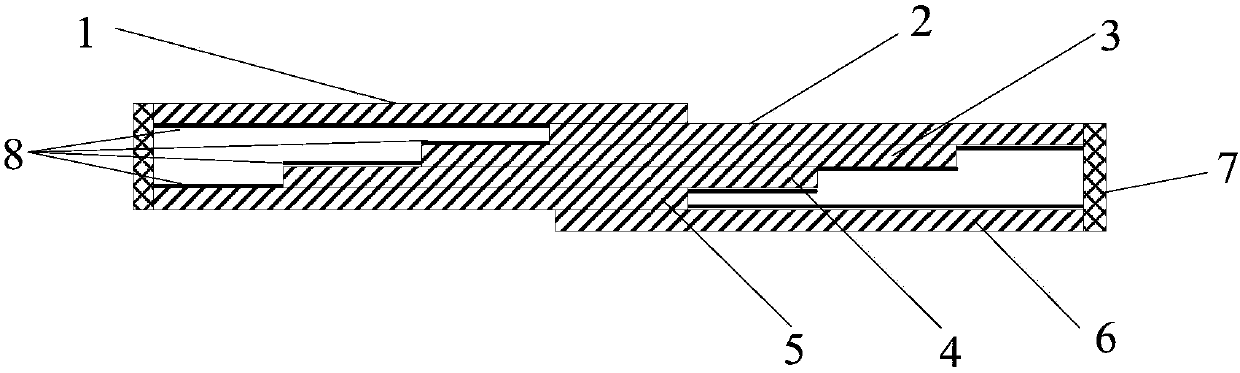

[0021] Specific implementation mode one: combine figure 1 Specifically illustrate this embodiment mode, a kind of optical F-P resonator that is used for semiconductor laser frequency stabilization in this embodiment mode is made of the first silicon dioxide substrate 1, the second silicon dioxide substrate 2, the 3rd silicon dioxide substrate 3, The fourth silicon dioxide substrate 4, the fifth silicon dioxide substrate 5, the sixth silicon dioxide substrate 6, and the seventh silicon dioxide substrate 7;

[0022] The lower surface of the first silicon dioxide substrate 1 is provided with a second silicon dioxide substrate 2, and the first silicon dioxide substrate 1 and the second silicon dioxide substrate 2 are arranged in dislocation, and the second silicon dioxide substrate 2 is located at the lower right of the first silicon dioxide substrate 1;

[0023] The lower surface of the second silicon dioxide substrate 2 is provided with a third silicon dioxide substrate 3, and ...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the first silicon dioxide substrate 1 is 10 microns to 500 microns. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the thickness of the second silicon dioxide substrate 2 is 10 microns to 500 microns. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com