Method for synthesizing solvent green 5

A synthesis method and solvent technology, applied in the field of synthesis of solvent green 5, can solve problems such as weather resistance defects and lack of vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of synthetic method of solvent green 5, synthetic method comprises the steps:

[0030] (1) Acylation reaction

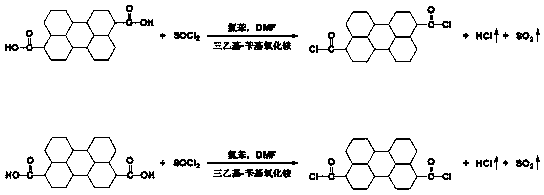

[0031] The mixture of 3,9-perylene diacid and 3,10-perylene diacid is produced by reacting 3,9-perylene dioic acid and 3,10-perylene diacid with sulfur oxychloride, and the reaction route is as follows:

[0032]

[0033] (2) Esterification reaction

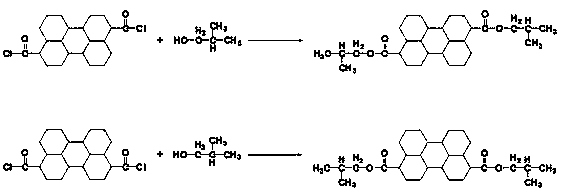

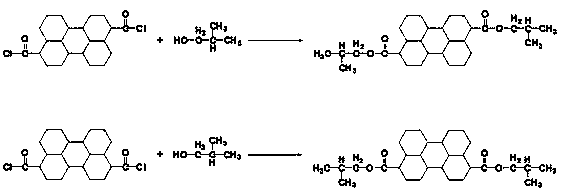

[0034] 3,9-perylene diacid chloride, 3,10-perylene diacid chloride react with isobutanol to generate 3,9-diisobutyl perylene diacid and 3,10-perylene diacid isobutyl ester, the reaction scheme is as follows:

[0035]

[0036] (3) Decolorization

[0037] Product 3,9-diisobutyl perylene diacid and 3,10-diisobutyl perylene diacid are crude products of solvent chlorine 5, and two kinds of adsorbents are added in the chlorobenzene solution of this crude product: activated carbon and activated clay , so that these two adsorbents can adsorb and refine the crude product at the same time, and th...

Embodiment 2

[0040] Example 2, in the synthesis method of solvent green 5 described in Example 1: add the slag material produced in steps (3) and (4) to the recovered chlorobenzene, then add activated carbon and activated clay to adsorb and refine again, After hot filtration to remove impurities, the filtrate is a mixture of chlorobenzene and methanol, recovered according to different fractions at different distillation temperatures, then add a certain amount of methanol to the filtrate, cool down and filter, the filtrate is a mixture of filter cake and methanol, and recover by distillation , The filter cake is recovered as the secondary crude product.

Embodiment 3

[0041] Embodiment 3, in the synthetic method of a kind of solvent green 5 described in embodiment 1 or 2: the specific steps of acylation reaction are: add unused chlorobenzene in the acylation kettle, then add perylene dioic acid, DMF and triethylbenzyl ammonium chloride, close the lid of the kettle, suck in an appropriate amount of unused thionyl chloride and recover the thionyl chloride by vacuum, and carry out the acylation reaction at 60°C-95°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com