Viscoelastic betaine surfactant as well as preparation method and application thereof

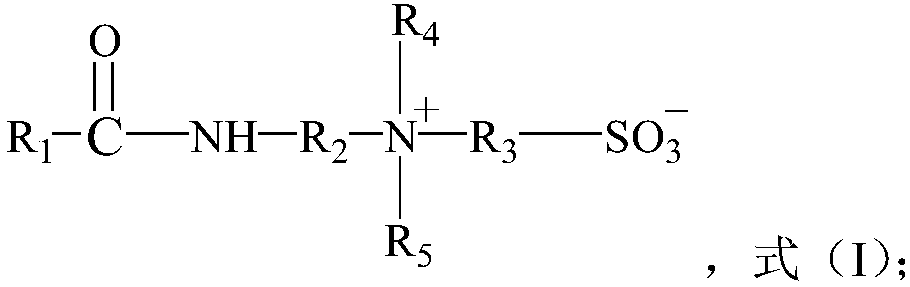

A technology of surfactant and betaine, which is applied in the field of viscoelastic betaine surfactant and its preparation and application, can solve the problems of low viscosity or interfacial activity, low oil displacement efficiency, formation plugging, etc., and achieve high interfacial activity, Improve oil displacement efficiency and increase surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Surfactant Preparation

[0030] (1) Erucamide sultaine surfactant (R 1 =C 21 , R 2 =C 3 , R 3 =C 3 h 6 O, R 4 and R 5 =C 1 )preparation

[0031] a) Add 0.5 mole of methyl erucate and the required amount of amidating reagent N,N-dimethylpropylenediamine into the reaction kettle, react at 140°C for 8 hours, turn on the vacuum pump, and remove the methanol and Excess N,N-dimethylpropylenediamine to obtain erucic acid acyl tertiary amine product, then add the required amount of 3-chloro-2-hydroxypropanesulfonate, react at 75°C for 9 hours, and use absolute ethanol After recrystallization and purification, long carbon chain betaine surfactant is obtained; wherein, methyl erucate: N, N-dimethylpropylenediamine: the molar ratio of 3-chloro-2-hydroxypropanesulfonate sodium is 1:2.5 :1.5.

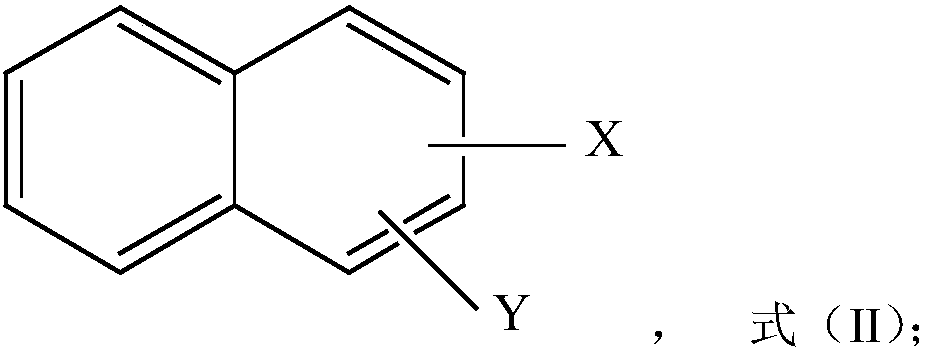

[0032] b) Naphthalene sulfonate and the erucamide sulfobetaine surfactant prepared by the present invention are respectively dissolved in water, stirred for 30 minutes, and for...

Embodiment 2

[0041] 1. Surfactant Preparation

[0042] (1) triacic acid amide sulfobetaine surfactant (R 1 =C 29 , R 2 =C 2 , R 3 =C 2 , R 4 and R 5 =C 1 )preparation

[0043] a) Add 0.5 mole of long-chain triacic acid methyl ester and the required amount of amidating reagent N,N-dimethylethylenediamine into the reaction kettle, react at 130°C for 6 hours, turn on the vacuum pump, and pump out the reaction Produced methanol and excess N,N-dimethylethylenediamine to obtain triacyl tertiary amine product, then add the required amount of sodium 2-chloroethylsulfonate, and react at 85°C for 15 hours. Obtain the long carbon chain betaine surfactant after water ethanol recrystallization purification; Wherein, the molar ratio of triacic acid methyl ester:N,N-dimethylethylenediamine:2-chloroethylsulfonate sodium is 1:2 :1.6.

[0044] b) Naphthalene sulfonate and triacic acid amide sulfobetaine surfactant prepared by the present invention are respectively dissolved in water, stirred for ...

Embodiment 3

[0048] 1. Surfactant Preparation

[0049] (1) nonanoic acid amide sultaine surfactant (R 1 =C 8 , R 2 =C 3 , R 3 =C 3 h 6 O, R 4 and R 5 =C 1 )preparation

[0050] a) Add 0.5 mole of nonanoic acid methyl ester and the required amount of amidating reagent N,N-dimethylpropylenediamine into the reaction kettle, react at 135°C for 10 hours, turn on the vacuum pump, and remove the methanol and Excessive N,N-dimethylpropylenediamine, to obtain nonanoic acid acyl tertiary amine product, then add the required amount of 3-chloro-2-hydroxypropanesulfonate sodium, react at 75 ° C for 10 hours, wash with absolute ethanol After recrystallization and purification, the long carbon chain betaine surfactant is obtained; wherein, the molar ratio of methyl nonanoate:N,N-dimethylpropylenediamine:3-chloro-2-hydroxypropanesulfonate sodium is 1:2 :1.5.

[0051] b) Naphthalene sulfonate and the nonanoic acid amide sulfobetaine surfactant prepared by the present invention were dissolved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com