Method for testing gelatin sample by adopting infrared spectroscopy

A technology of infrared spectroscopy and gelatin, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of influence of test results, high price, erosion, etc., and achieve accurate and reliable infrared test results, and the preparation method is simple and easy. The effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

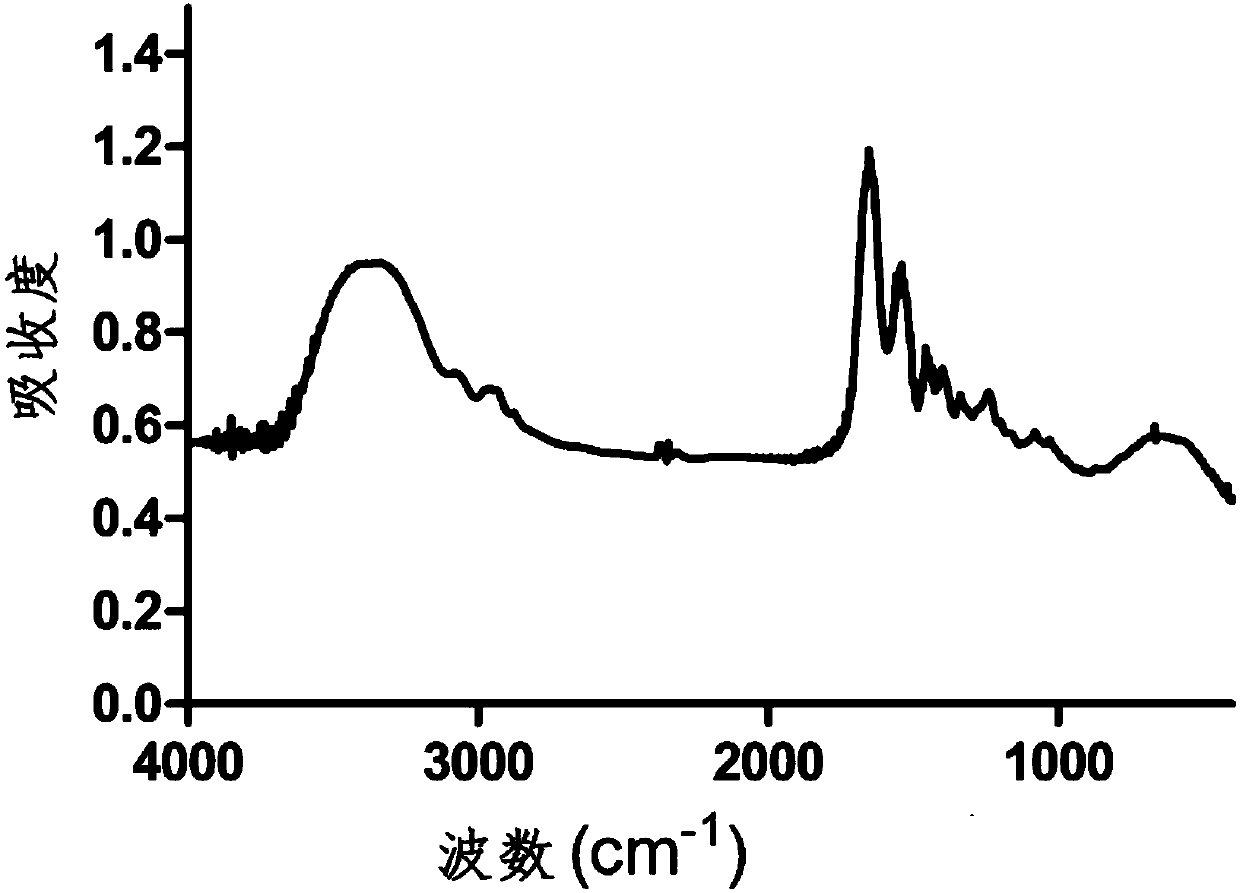

[0040]Mix 0.05 g of gelatin particles with 99.95 g of water at 20° C., swell for 1 hour, and dissolve in a 60° C. water bath for 30 minutes to obtain a glue solution with a gelatin concentration of 0.05 wt %. The glue solution was placed in a centrifuge tube, pre-frozen at -20°C for 3 hours, and then freeze-dried at -80°C for 24 hours to obtain a freeze-dried powder, which was stored in a desiccator. Potassium bromide was dried at 105°C for 4 hours and stored in a desiccator. Mix and grind 1 mg of freeze-dried powder and 200 mg of potassium bromide to obtain a uniform mixed powder. Put the mixed powder in a mold, press it on a hydraulic press with a pressure of 50 MPa for 60 seconds, and release the pressure to obtain a light-transmitting sheet. Conduct an infrared test, and the result is see figure 1 .

Embodiment 2

[0042] Mix 0.5 g of gelatin particles with 99.5 g of water at 15° C., swell for 2 hours, and dissolve in a 60° C. water bath for 40 minutes to obtain a gelatin solution with a gelatin concentration of 0.5 wt %. The glue solution was placed in a centrifuge tube, pre-frozen at -25°C for 2 hours, and then freeze-dried at -70°C for 30 hours to obtain a freeze-dried powder, which was stored in a desiccator. Potassium bromide was dried at 105°C for 4 hours and stored in a desiccator. Mix and grind 2 mg of freeze-dried powder and 200 mg of potassium bromide to obtain a uniform mixed powder, place the mixed powder in a mold, press on a hydraulic press with a pressure of 100 MPa for 45 seconds, and release the pressure to obtain a light-transmitting sheet for infrared testing.

Embodiment 3

[0044] Mix 1 g of gelatin particles with 99 g of water at 20° C., swell for 1 hour, and dissolve in a 60° C. water bath for 30 minutes to obtain a gelatin solution with a gelatin concentration of 1 wt%. The glue solution was placed in a centrifuge tube, pre-frozen at -20°C for 3 hours, and then freeze-dried at -80°C for 24 hours to obtain a freeze-dried powder, which was stored in a desiccator. Potassium bromide was dried at 105°C for 4 hours and stored in a desiccator. Mix and grind 2 mg of freeze-dried powder and 200 mg of potassium bromide to obtain a uniform mixed powder, place the mixed powder in a mold, press on a hydraulic press with a pressure of 50 MPa for 60 seconds, and release the pressure to obtain a light-transmitting sheet for infrared testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com