A Combined Interferometric Cavity for Wavelength Selective Output of Chemical Lasers

A wavelength selection and laser technology, applied in the field of combined interference cavity, to achieve the effect of avoiding insertion loss and high anti-damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

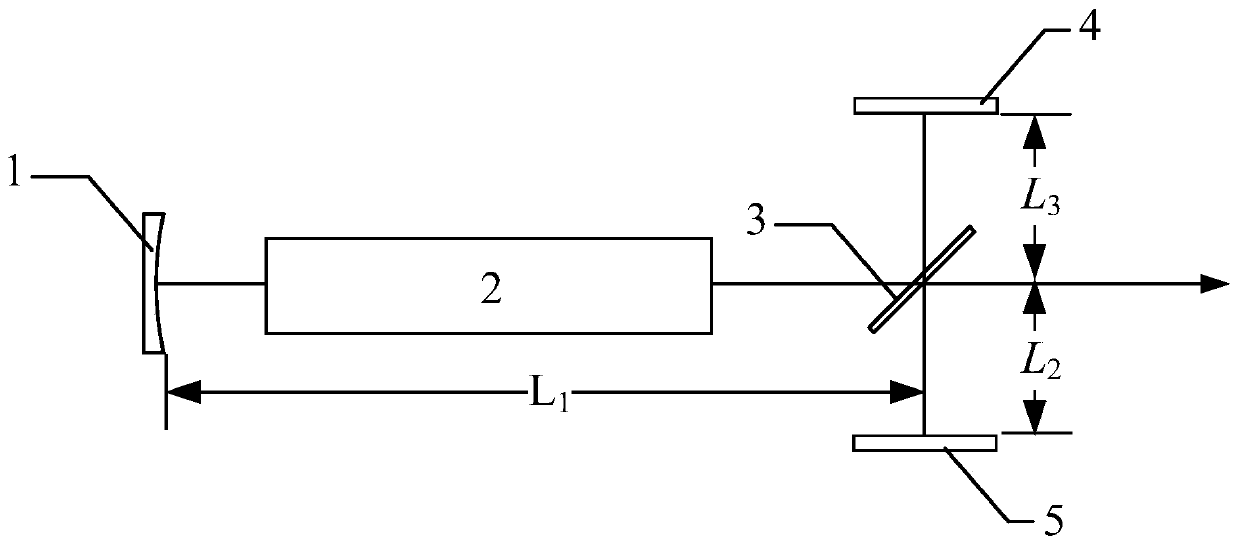

[0020] as attached figure 1 As shown, a combined interference cavity for chemical laser wavelength selective output, the laser resonator includes a concave cut-off mirror 1, a laser gain region 2, a 45-degree beam splitter 3, a first plane cut-off mirror 4, a second Flat cut-off mirror 5. All optical components are fixed on a vibration-isolation platform in a vacuum chamber. The optical axis of the optical cavity passes through the centers of the concave cut-off mirror 1, the laser gain region 2, the reflective surface of the 45-degree beam splitter 3, the first plane cut-off mirror 4, and the second plane cut-off mirror 5 respectively. The first plane cut-off mirror 4, the 45-degree beam splitter 3 and the second plane cut-off mirror 5 jointly constitute the interference sub-cavity of the laser optical cavity; the first plane cut-off mirror 4 is arranged opposite to the second plane cut-off mirror 5, They are respectively located on both sides of the 45-degree beam splitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com