Automatic toxin removing device for raw cassava

An automatic raw cassava and cassava technology, applied in vegetable or fruit peeling, metal processing, food science, etc., can solve the problems of long time consumption, difficulty in satisfying, poisoning, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now do further detailed explanation in conjunction with accompanying drawing.

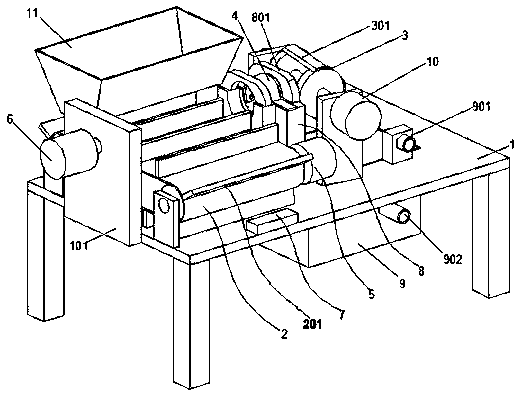

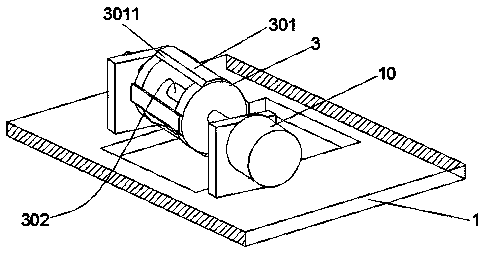

[0020] like Figures 1 to 4 As shown, an automatic raw cassava detoxification device, including machine frame 1, conveyor belt 2, slicing wheel 3, leather cutting ring 4, A motor 5, hydraulic cylinder 6, PLC7, base 8, soaking tank 9, B motor 10 and hopper 11.

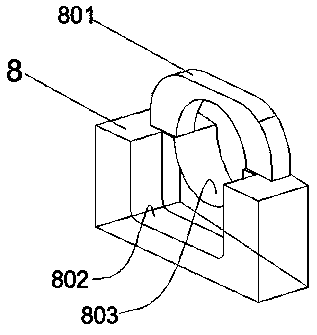

[0021] like Figure 1-4 As shown, the setup rack 1 is provided with a mounting plate and 4 feet. The conveyor belt 2 is installed on the left end of the mounting plate of the frame 1, and the A motor 5 drives it to rotate. The surface is divided into several squares with a square plate 201. The left end is installed with a hydraulic cylinder 6, and the right end is installed with a base 8, and the setting base 8 is fixed on the frame 1. On the top, it is a right-angled trapezoid, with a square pit 802 on the left side to avoid the empty cutting apron, and an arc groove 803 on the right side, the center of the circle is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com