Method for preparing tobacco flavor with caprylic capric triglyceride and application of tobacco flavor to cigarette bead blasting

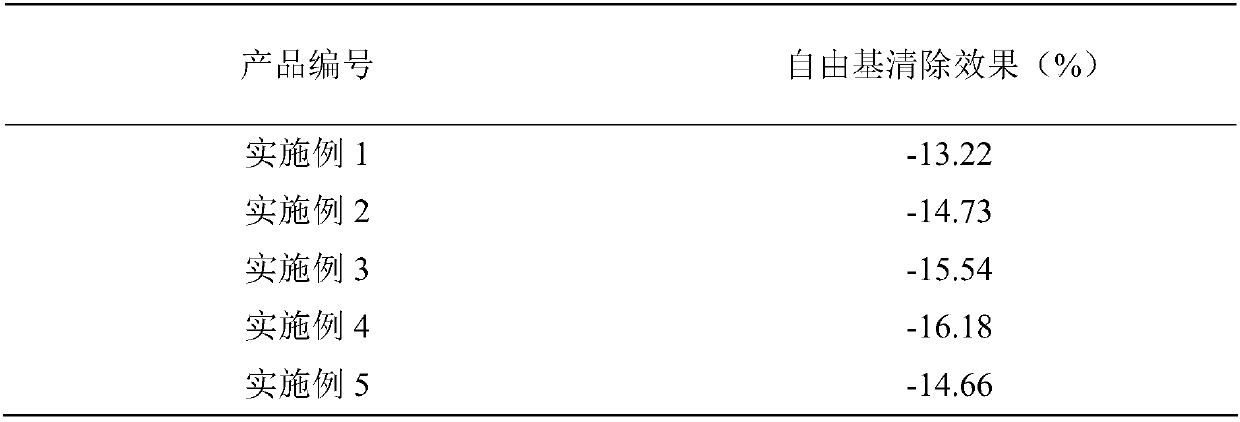

A caprylic capric acid glyceride, tobacco flavoring technology, applied in the direction of essential oil/fragrance, application, tobacco, etc., can solve the problems such as the characteristic aroma style of the raw material is not obvious, cannot meet the use requirements, and the natural aroma of the aroma is weak, etc., to improve The airtightness of the capsule wall, the content of scavenging free radicals, and the effect of rich and full fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The coriander seed raw material is dried and pulverized, and passed through a 40-mesh sieve to make a coriander seed powder product. Weigh 0.1kg of coriander seed powder, 1.5kg of caprylic acid glyceride, and 0.8g of vitamin E, put them into a three-necked flask, connect the reflux condenser, start the oil bath heating equipment, control the temperature at 120°C, and keep stirring The treatment was carried out for 3 hours, and then naturally cooled to room temperature. The obtained material is coarsely filtered with gauze, and then filtered with a 0.8 μm microporous membrane to remove impurities and a small amount of insoluble matter, thereby obtaining the flavoring for tobacco of the present invention.

Embodiment 2

[0026] The marigold petals are dried and pulverized, and passed through a 20-mesh sieve to make a marigold powder product. Weigh 0.1kg of marigold powder, 1.6kg of caprylic capric acid glyceride, put them into a three-neck flask, 1.3g of vitamin E, connect the reflux condenser, start the oil bath heating equipment, control the temperature at 110°C, and keep stirring After 2 hours, cool down to room temperature naturally. The obtained material is coarsely filtered with gauze, and then filtered with a 0.8 μm microporous membrane to remove impurities and a small amount of insoluble matter, thereby obtaining the flavoring for tobacco of the present invention.

Embodiment 3

[0028] After drying and pulverizing the lavender, pass through a 40-mesh sieve to make a lavender powder product. Weigh 0.1kg of lavender powder, 1.8kg of caprylic acid glyceride, and 1.8g of vitamin E, put them into a three-necked flask, connect the reflux condenser, start the oil bath heating equipment, control the temperature at 130°C, and keep stirring Processed for 2.5 hours, and cooled naturally to room temperature after the end. The obtained material is coarsely filtered with gauze, and then filtered with a 0.8 μm microporous membrane to remove impurities and a small amount of insoluble matter, thereby obtaining the flavoring for tobacco of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com