Multifunctional bamboo cotton composite fabric

A composite fabric and multi-functional technology, applied in the textile field, can solve the problems of finding antibacterial and antistatic fabrics, and achieve the effect of quick drying and comfortable inner layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

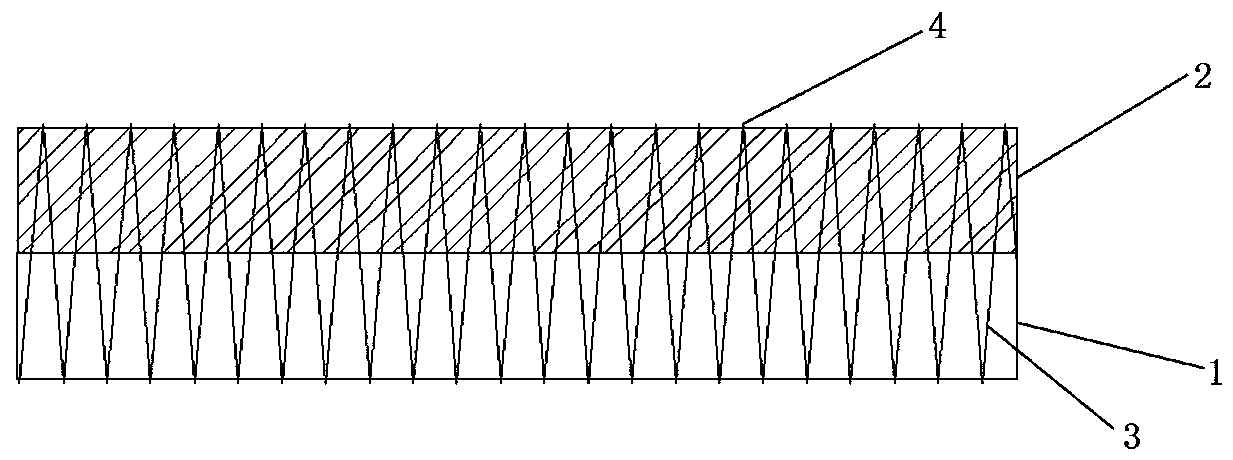

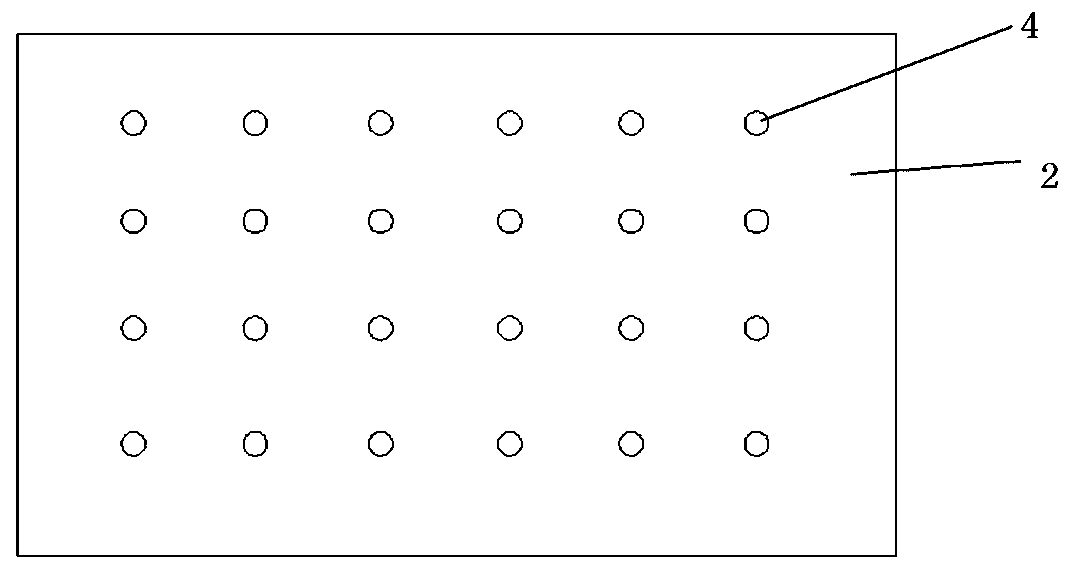

[0017] A multifunctional bamboo-cotton composite fabric, composed of an inner layer 1 and an outer layer 2, the inner layer 1 is an antistatic thermal layer, and the outer layer 2 is a hydrophobic layer, and the antistatic thermal layer is made of multifunctional composite yarn The hydrophobic layer is woven with hydrophobic yarn, the inner layer 1 and the outer layer 2 are connected together by low-denier yarn 3, and the low-denier yarn 3 runs through the inner layer 1 and the outer layer 2. The inner layer 1 and the outer layer 2 are connected together, and the surfaces of the inner layer 1 and the outer layer 2 are evenly arranged with connection points formed by low-denier yarns, and the multifunctional composite yarn is made of a single bamboo The fiber is twisted with a single cotton fiber to form a yarn, which is then scoured and treated with a composite finishing agent. The hydrophobic yarn is formed by twisting a single bamboo fiber and a single cotton fiber to form a ...

Embodiment 2

[0019] Washing Durability Test

[0020] With reference to the "GB / T8629-2001 Home Washing and Drying Program for Textile Tests" standard, a kind of multifunctional bamboo-cotton composite fabric of Example 1 is washed, repeated several times, and then the quick-drying test of the inner layer of the fabric and the outer surface are carried out. Water repellency test of the layer surface.

[0021] The quick-drying test of the inner layer of the fabric is as follows: (1) Cut out 5 samples from the sample, the size of each sample is 10cm×10cm, and the samples should be smooth and wrinkle-free. (2) Place the sample under standard atmospheric conditions to adjust the humidity balance. (3) Place the sample flat on the test bench (inner layer facing up), absorb about 0.2ml of water and gently drop it on the sample, the diameter of the dropper should not exceed 1cm from the surface of the sample. (4) Carefully observe the diffusion of water droplets, and record the time required for ...

Embodiment 3

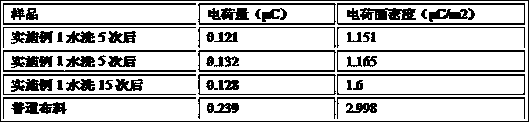

[0031] Persistence test of antistatic ability

[0032] Refer to the standard of "GB / T8629-2001 Household Washing and Drying Procedures for Textile Tests", wash the samples 5, 10, and 20 times respectively, and then test them in YG(B) according to GB / T12703.2-2009 "Textile Electrostatic Test Method". The surface charge of the cloth sample is measured on the 403-type fabric friction electrification tester. The more the charge, the worse its antistatic property; the less the charge, the better its antistatic property.

[0033] Measure the electric charge of embodiment 1 of the present invention and common cloth on the market respectively, and the measurement results are as follows:

[0034] Table 3 Surface charge corresponding to each cloth sample

[0035]

[0036] It can be seen from the above table that the surface charge and the surface charge area density of Embodiment 1 of the present invention have obvious antistatic ability compared with the common cloth on the market,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com