Preparation method for Mn:YAG fluorescent powder, and Mn:YAG laminated fluorescent glass as well as preparation method and application of glass

A fluorescent glass and fluorescent powder technology, applied in the field of LED fluorescent materials, can solve the problems of shortened service life, easy to be corroded by air, unstable phosphor powder, etc., and achieve longer service life, avoid the influence of light effect, and stable and uniform interlayer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

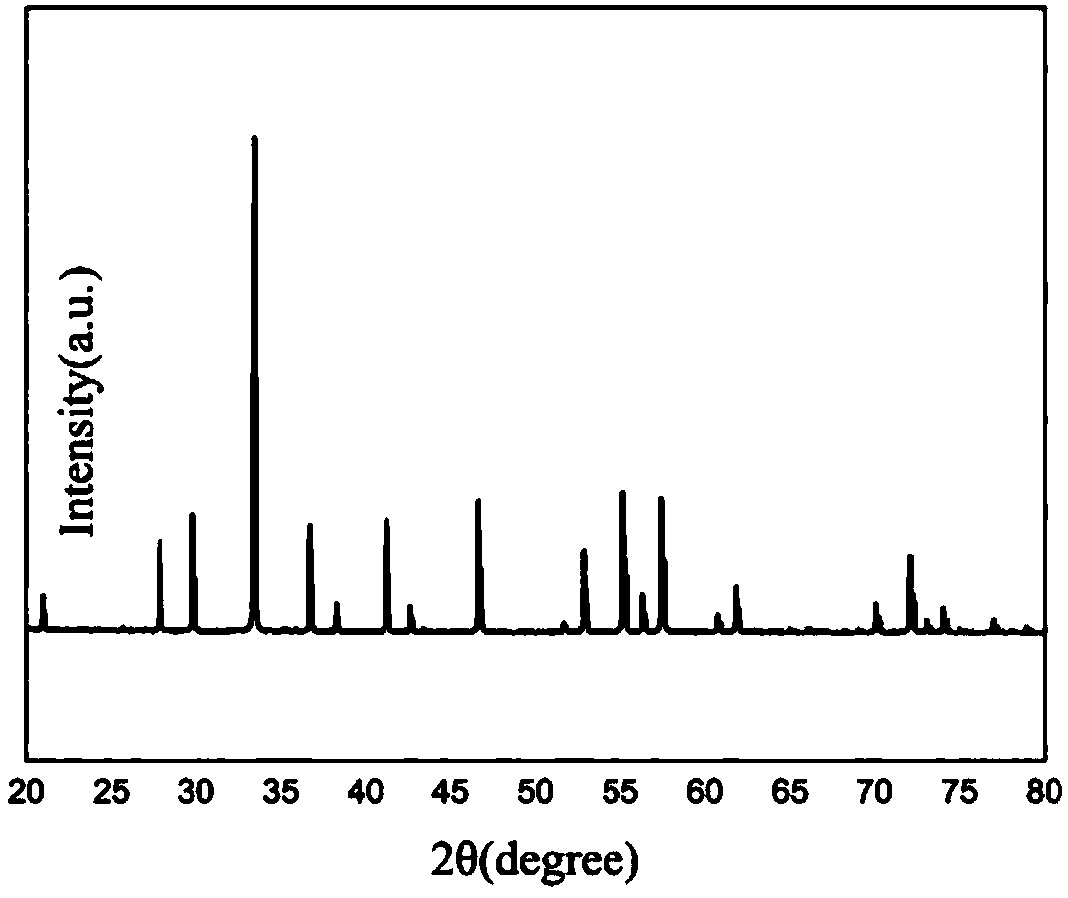

[0055] Such as figure 1As shown in the figure, the Mn: YAG phosphor ink is printed on a φ55 glass plate 1 with a thickness of 0.5 mm through a 100-mesh screen, and it is placed in a muffle furnace, and it takes 6 hours to rise from room temperature to 200°C and keep warm for 2 hours. Then close the muffle furnace, cool to room temperature, and cover the glass 3 on the glass substrate on the side with the Mn:YAG phosphor. Put it into a high-temperature furnace, raise it to 700°C for 1.5 hours, keep it warm for 3 minutes, close the high-temperature furnace, cool to room temperature, and then obtain a piece of Mn:YAG fluorescent laminated glass. Wherein, the glass plate of φ55 is borosilicate glass.

[0056] The Mn:YAG phosphor is composed of: Y 2 o 3 : 55 parts, Al 2 o 3 : 45 parts, MnCO 3 : 1 copy, HBO 3 : 2 parts, BeO 1 part and Er 2 o 3 0.5 parts are accurately weighed, then put into an agate mortar, mixed and ground evenly, the ground raw materials are sintered at...

Embodiment 2

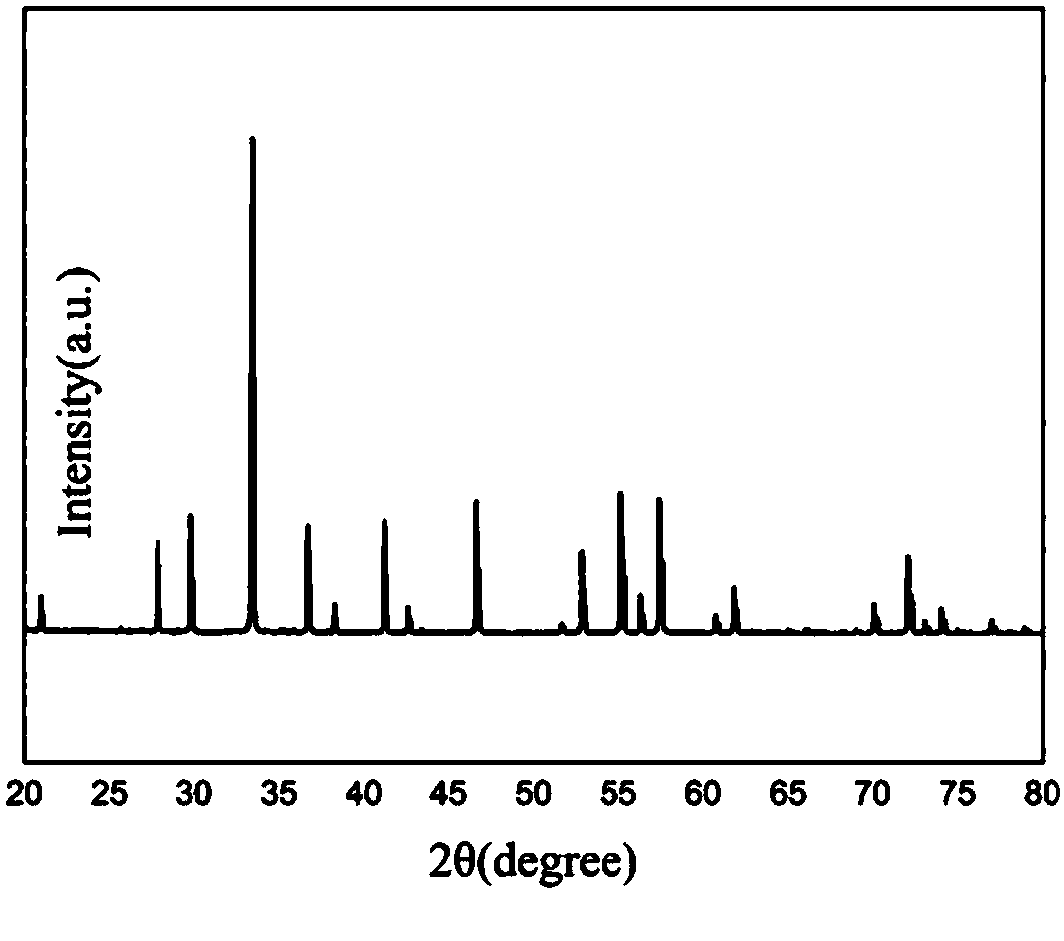

[0073] In this embodiment, be that among the embodiment 1, use 6 hours to rise from room temperature to 200 ℃, and keep warm for 2 hours. Then close the muffle furnace, cool to room temperature, and cover the glass 3 on the glass substrate on the side with the Mn:YAG phosphor. Put it into a high-temperature furnace, raise it to 700°C in 1.5 hours, keep it warm for 3 minutes, change it to take 8 hours to rise from room temperature to 300°C, and keep it at 300°C for 1 hour, then cool to room temperature, close the muffle furnace, and automatically cool down After reaching room temperature, place the glass plate sample in a high-temperature furnace to raise the temperature from room temperature to 600°C for 1 hour, and keep the temperature at 600°C for 3 minutes, then close the high-temperature furnace, and then cool down to room temperature with the furnace to obtain Mn:YAG fluorescent glass. The rest are the same as in Embodiment 1, and will not be repeated.

[0074] The prepa...

Embodiment 3

[0076] In this embodiment, the Mn:YAG phosphor laminated glass obtained in the above example and the Ce:YAG glass-ceramics are combined on a blue light chip to form a light source structure. The packaging process of the light source is simple, and the life of the light source is longer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com