Air compressor heat recovery device control system

A heat recovery device and control system technology, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as difficult to improve equipment production efficiency and utilization rate, inability to recycle, heat can not be used, etc., to achieve heat Effects of recycling, reducing heat waste, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

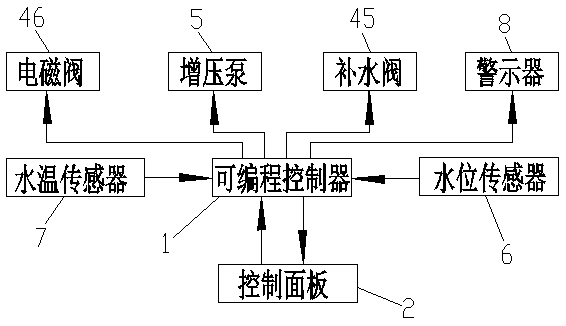

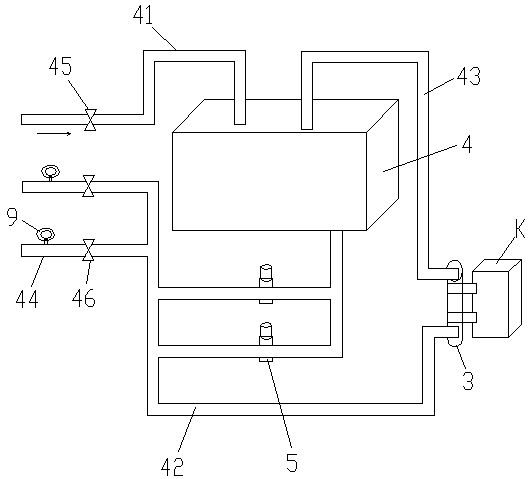

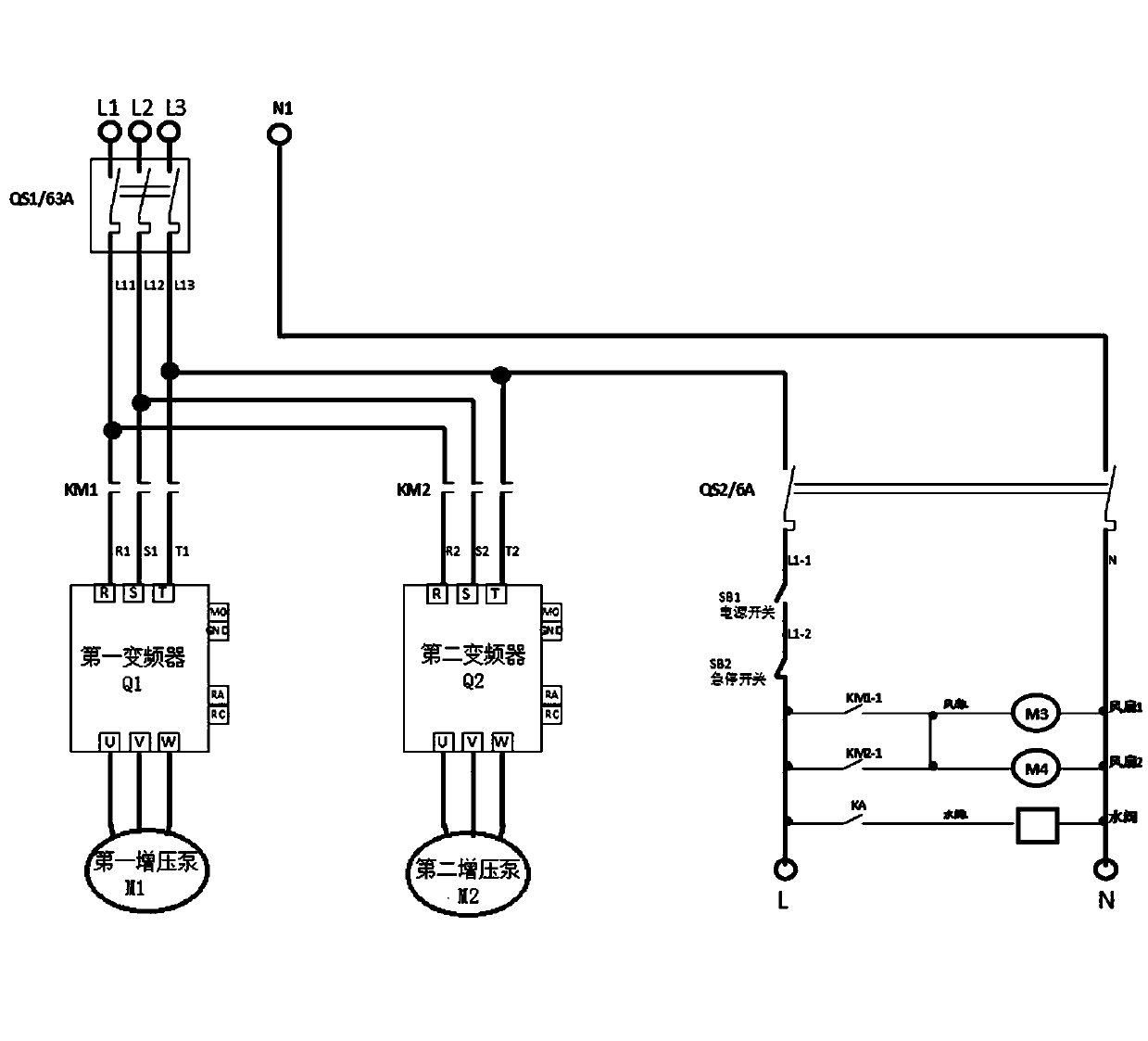

[0021] Figure 1 to Figure 3 It is a schematic diagram of the principle and structure of the embodiment of the present invention.

[0022] The reference signs are: air compressor K, programmable controller 1, control panel 2, cooler 3, hot water storage tank 4, water supply pipe 41, circulating water inlet pipe 42, circulating water return pipe 43, water supply pipe 44, Filling water valve 45, solenoid valve 46, booster pump 5, water level sensor 6, water temperature sensor 7, warning device 8.

[0023] like Figure 1 to Figure 3 As shown, the present invention discloses a control system of an air compressor heat recovery device. The control system includes a programmable controller 1 arranged in a control circuit, an air compressor heat recovery device, a control panel 2 and a control cabinet. The programmable controller 1 is the core contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com