Low-temperature testboard of sensor equipment

A technology of sensor equipment and low-temperature testing, which is applied in the direction of calibration/testing of force/torque/power measuring instruments, instruments, and measuring devices. It can solve the problems of plastic deformation of superconducting cavities, increased testing costs, and high testing costs. The effects of small footprint and area, reduced cooling mass, and shortened rewarming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

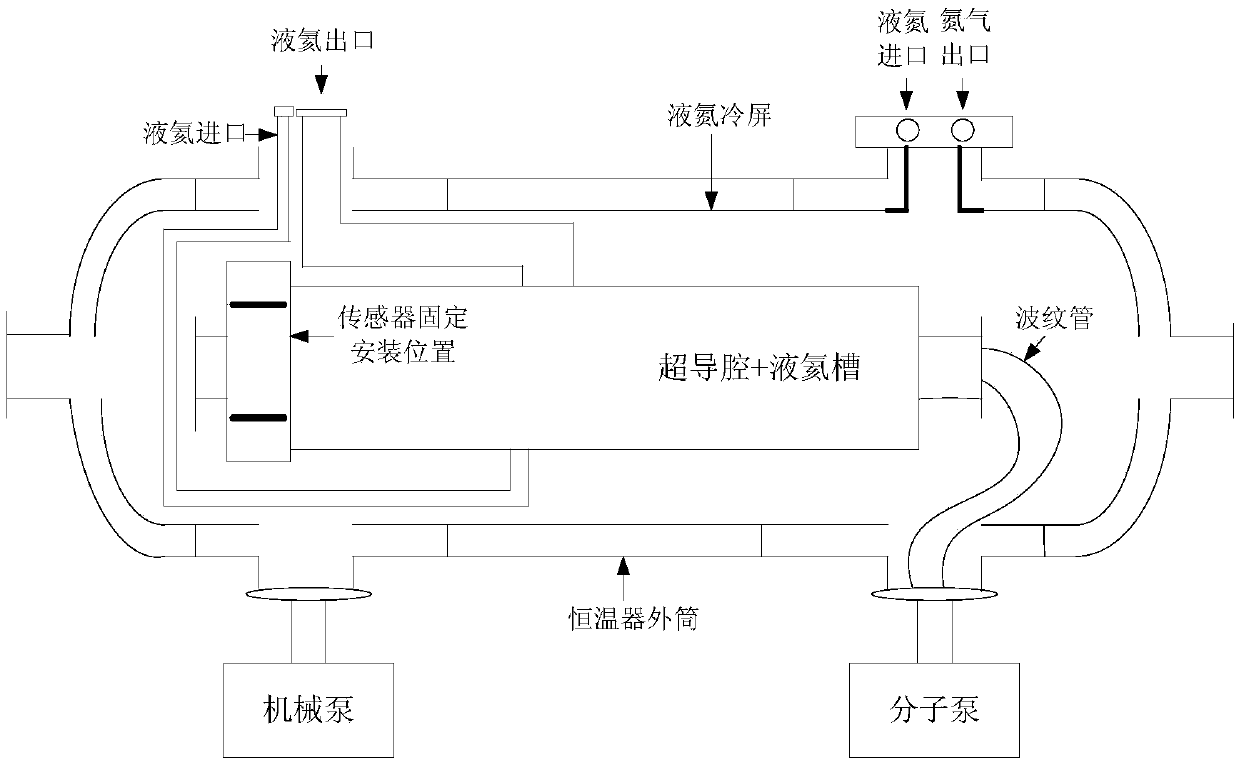

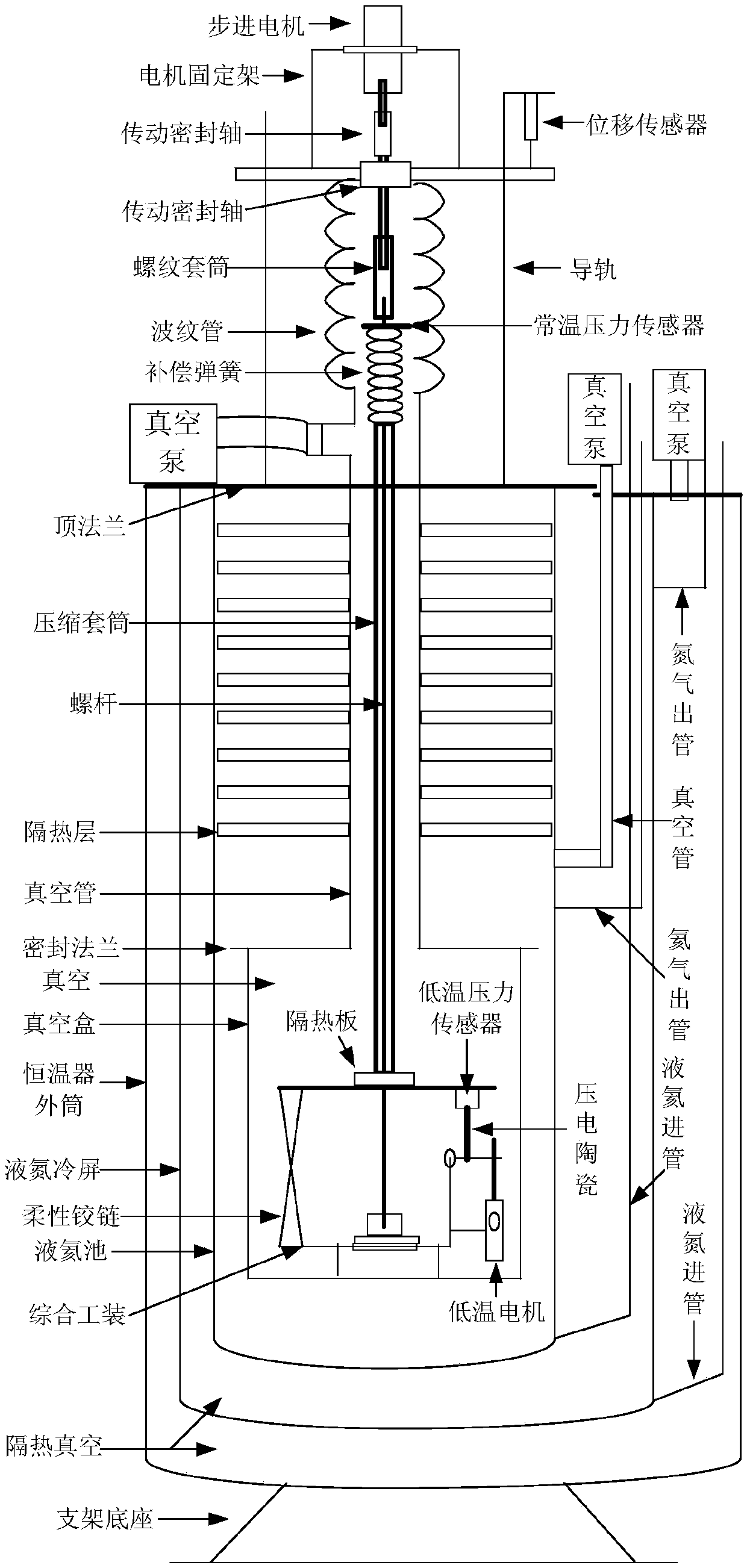

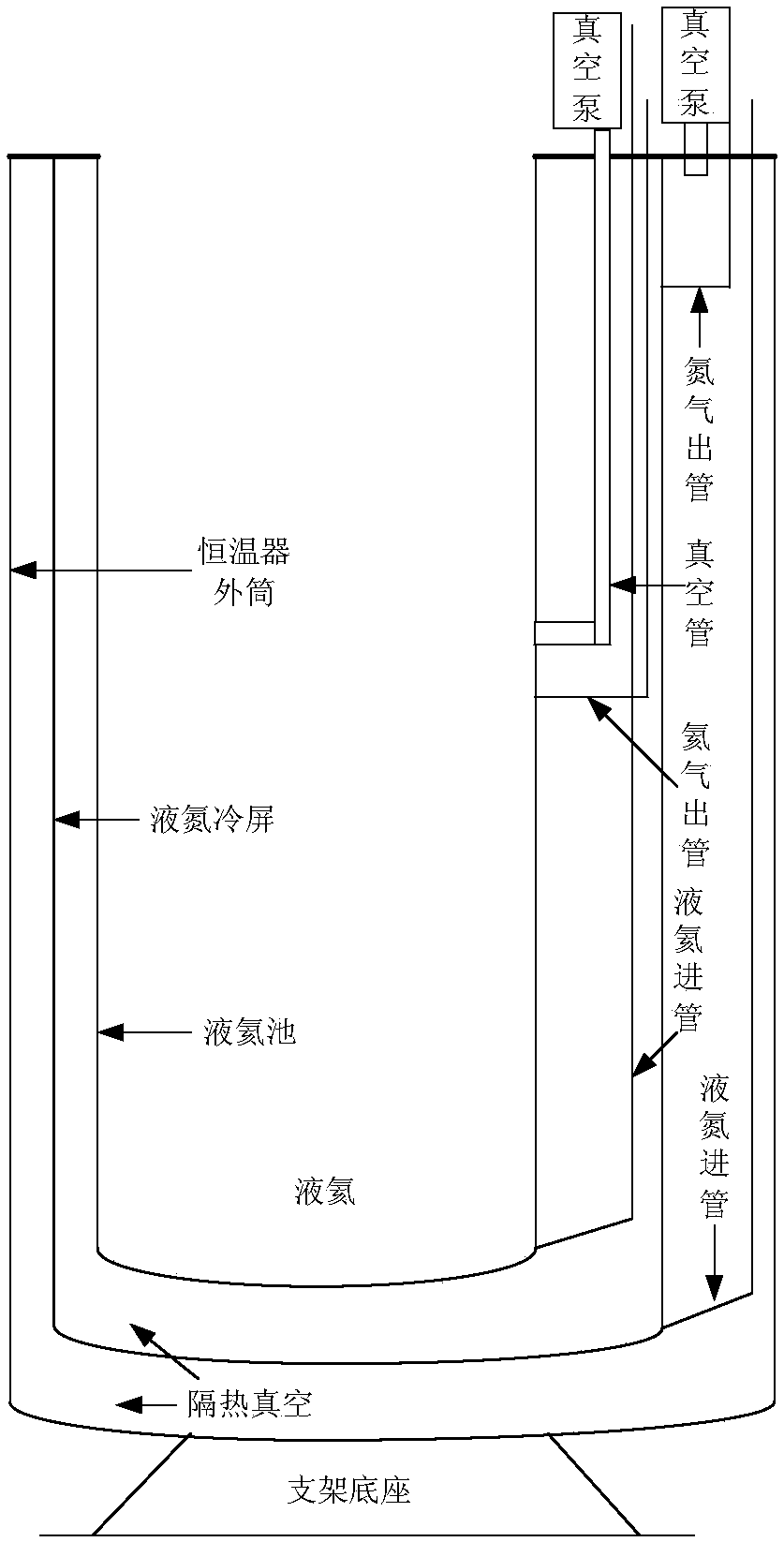

[0042] In order to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] The material for making the sensor low temperature test bench requires high mechanical strength and good low temperature performance. The main body of the test bench: the top flange, the outer cylinder of the thermostat, the liquid helium pool, the vacuum box, the vacuum tube, and the main arm and auxiliary arm of the comprehensive tooling table can all be made of 304 stainless steel. The heat insulation layer is made of hard foam material and reinforced on the outside with metal aluminum sheets. The compression sleeve can be made of copper-nickel alloy with relatively small thermal conductivity, or high-strength composite material. The heat insulation board can be made of G10 material to reduce the temperature of the low temperature system. to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com