Feed additive for improving reproduction performance of pregnant sows and preparing method of feed additive

A feed additive and production performance technology, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of uneven quality of medicinal materials, high production costs, and difficulty in controlling active ingredients, and achieve easy configuration , The cost is moderate, and the effect of improving the survival rate and the health rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Obtained by the following steps:

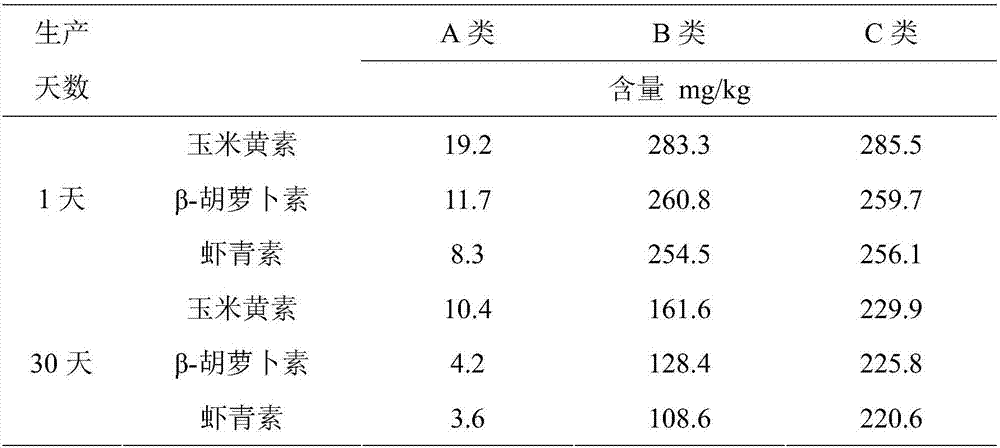

[0029] Step 1. Mix zeaxanthin, β-carotene, and astaxanthin according to the weight ratio of 1.5:4.5:2.5 to make a carotenoid mixed preparation, and prepare this kind of carotene mixed preparation with soybean oil according to the weight ratio of 2.5:6.5 Carotenoid suspension, and completely dissolve the suspension at 85°C;

[0030] Step 2, mixing starch, sodium alginate, β-cyclodextrin, and polyhydantoin according to a weight ratio of 3.5:1.5:1.5:1.5 to make a coating agent;

[0031] Step 3. Uniformly disperse the carotenoid suspension and coating agent under high pressure of 25Mpa respectively; then spray dry and mix according to the weight ratio of carotenoid suspension: coating agent = 1:8 to make carotenoid Carotene coating agent;

[0032] Step 4: 950 parts by weight of carotenoid coating agent, 1450 parts of sodium diacetate, 450 parts of ferrous fumarate, 280 parts of sodium butyrate, 140 parts of coated Bacillus subtilis, and ...

Embodiment 2

[0034] Obtained by the following steps:

[0035] Step 1. Mix zeaxanthin, β-carotene, and astaxanthin according to the weight ratio of 2:5:3 to prepare a carotenoid mixed preparation, and prepare such a carotene mixed preparation with soybean oil according to a weight ratio of 3:7 Carotenoid suspension, and completely dissolve the suspension at 90°C;

[0036] Step 2, mixing starch, sodium alginate, β-cyclodextrin, and polyhydantoin in a weight ratio of 4:2:2:2 to make a coating agent;

[0037] Step 3: Uniformly disperse the carotenoid suspension and coating agent under 32Mpa high pressure respectively; then spray dry and mix according to the weight ratio of carotenoid suspension: coating agent = 1:9 to make carotenoid Carotene coating agent;

[0038]Step 4: 1000 parts of carotenoid coating agent, 1500 parts of sodium diacetate, 500 parts of ferrous fumarate, 300 parts of sodium butyrate, 150 parts of coated Bacillus subtilis, and 100 parts of coated lactobacillus by weight ,...

Embodiment 3

[0040] Obtained by the following steps:

[0041] Step 1. Mix zeaxanthin, β-carotene, and astaxanthin according to the weight ratio of 2.5:5.5:3.5 to make a carotenoid mixed preparation, and prepare this kind of carotene mixed preparation with soybean oil according to the weight ratio of 3.5:7.5 Carotenoid suspension, and completely dissolve the suspension at 100°C;

[0042] Step 2, starch, sodium alginate, β-cyclodextrin, and polyhydantoin are made into a coating agent according to the weight ratio of 4.5:2.5:2.5:2.5;

[0043] Step 3: Uniformly disperse the carotenoid suspension and the coating agent under 40Mpa high pressure respectively; then spray dry and mix according to the weight ratio carotenoid suspension: coating agent = 1:10 to make the carotenoid suspension Carotene coating agent;

[0044] Step 4: 1050 parts of carotenoid coating agent, 1550 parts of sodium diacetate, 550 parts of ferrous fumarate, 320 parts of sodium butyrate, 160 parts of coated Bacillus subtili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com