A kind of preparation method of pure natural facial mask

A pure natural, facial mask technology, applied in the direction of layered products, can solve the problems of low mask strength and low utilization rate of essence, and achieve the effect of high utilization rate of essence, lower production cost, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

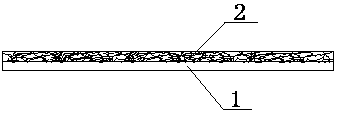

[0024] see figure 1 , a kind of preparation method of pure natural face mask, described preparation method comprises the following steps:

[0025] The first step: configuring the essence, preparing the essence from the Bletilla striata extract, glycerin and distilled water, wherein the volume percentage of the Bletilla striata extract is 10%-30%, and the glycerol content is 5%-20%;

[0026] The second step: Spinning film, laying the mask base fabric 1 on the spinning machine, putting the essence into the storage tank of the spinning machine, turning on the switch of the spinning machine to spin, the essence silk is evenly attached to the mask The mask essence layer 2 is formed on the base fabric 1, and the spinning and film making is completed at this time;

[0027] The third step: drying and cutting, the finished mask is dried, the drying temperature is 50-70 degrees Celsius, the humidity of the mask is 20%-30%, and then the dried mask base fabric 1 is cut into a mask;

[0...

Embodiment 1

[0042] A kind of preparation method of pure natural face mask, described preparation method comprises the following steps:

[0043] The first step: configure the essence, prepare the essence with Bletilla striata extract, glycerin and distilled water, wherein the volume percentage content of the Bletilla striata extract is 20%, and the volume percentage content of the glycerin is 5%;

[0044] The second step: Spinning film, laying the mask base fabric 1 on the spinning machine, putting the essence into the storage tank of the spinning machine, turning on the switch of the spinning machine to spin, the essence silk is evenly attached to the mask The mask essence layer 2 is formed on the base fabric 1, and the spinning and film making is completed at this time;

[0045] The third step: drying and cutting, the finished mask is dried, the drying temperature is 50-70 degrees Celsius, the humidity of the mask is 20%-30%, and then the dried mask base fabric 1 is cut into a mask;

[00...

Embodiment 2

[0048] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0049] The spinning film of the second step is centrifugal spinning, and the spinning steps are as follows: put the essence into the storage tank of the centrifugal spinning machine, turn on the switch of the spinning machine to carry out centrifugal spinning, and the essence mucus is centrifuged After spinning, the essence silk with a diameter of 100 nanometers to 10 microns is obtained. The mask base fabric 1 moves at a constant speed at a linear speed of 1m / min-10m / min, and the essence silk falls and evenly adheres to the mask base fabric 1 to form a mask. Essence layer 2, at this time the centrifugal spinning is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com