Clopidogrel hydrogen sulfate tablet as well as preparation method and use

A technology of clopidogrel bisulfate tablets and clopidogrel bisulfate, which is applied in the field of clopidogrel bisulfate tablets and its preparation, can solve the problems of easy sticking, poor stability and poor fluidity of finished preparations, and reduce The effect of fine powder amount, prolonged drying time, and improvement of fluidity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

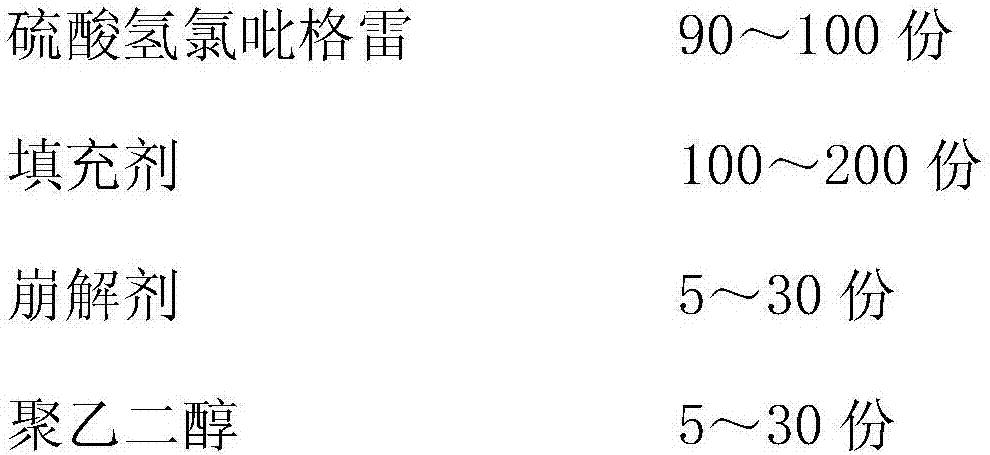

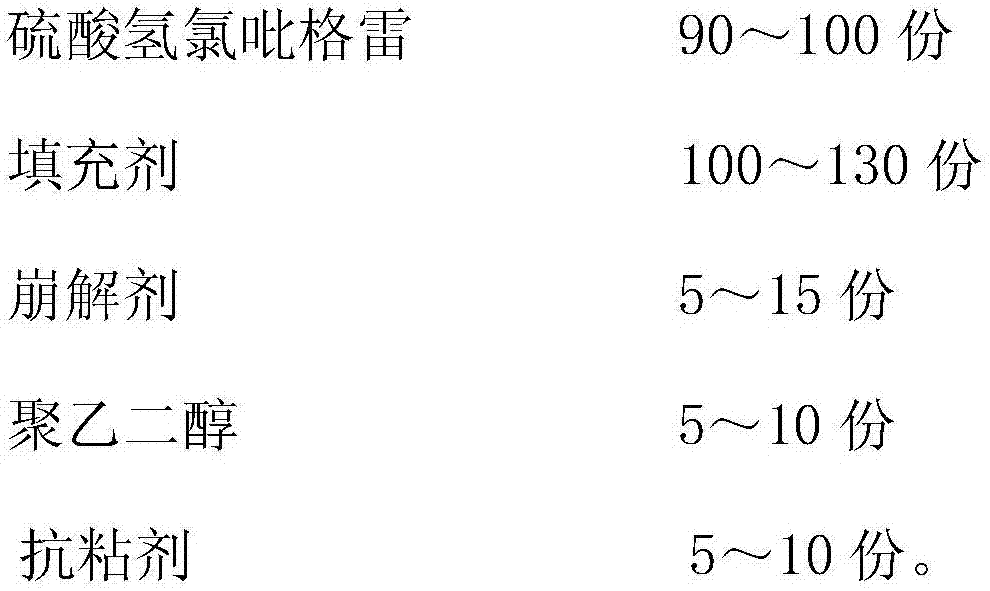

Method used

Image

Examples

Embodiment 1

[0036]

[0037]

[0038] The preparation method comprises the following steps:

[0039] S1. Polyethylene glycol 6000 is mixed with ethanol with a purity of 70% to obtain a 10% polyethylene glycol solution;

[0040] S2. Put clopidogrel bisulfate, microcrystalline cellulose, mannitol, low-substituted hydroxypropyl cellulose, and polyethylene glycol 6000 in a wet granulator, mix for 5 minutes until fully mixed, and then add 10% polyethylene glycol Ethylene glycol solution, make soft material for 1 minute, and granulate through a swing granulator (20 mesh stainless steel sieve);

[0041] S3. Dry the wet granules in a boiling dryer, set the air inlet temperature to 60°C, dry until the material temperature reaches 40°C, stop heating, discharge, and granulate with a 18-mesh sieve;

[0042] S4, mixing the sized clopidogrel hydrogen sulfate particles with hydrogenated castor oil with a particle size of 75 microns, and compressing the mixed product into tablets;

[0043] S5. Coa...

Embodiment 2

[0045]

[0046]

[0047] The preparation method comprises the following steps:

[0048] S1. Polyethylene glycol 4000 is mixed with ethanol with a purity of 60% to obtain a 10% polyethylene glycol solution;

[0049] S2. Put clopidogrel bisulfate, microcrystalline cellulose, mannitol, low-substituted hydroxypropyl cellulose, and polyethylene glycol 4000 in a wet granulator, mix for 5 minutes until fully mixed, and add 10% polyethylene glycol Glycol solution, making soft material for 1 minute, granulating through a swinging granulator (20 mesh stainless steel sieve);

[0050] S3. Dry the wet granules in a boiling dryer, set the air inlet temperature to 60°C, dry until the material temperature reaches 40°C, stop heating, discharge, and granulate with a 18-mesh sieve;

[0051] S4, mixing the sized clopidogrel hydrogen sulfate particles with hydrogenated castor oil with a particle size of 100 microns, and compressing the mixed product into tablets;

[0052] S5. Coating to ob...

Embodiment 3

[0054]

[0055] The preparation method comprises the following steps:

[0056]S1. Polyethylene glycol 5000 is mixed with ethanol with a purity of 80% to obtain a 10% polyethylene glycol solution;

[0057] S2. Put clopidogrel bisulfate, microcrystalline cellulose, mannitol, low-substituted hydroxypropyl cellulose, and polyethylene glycol 5000 in a wet granulator, mix for 5 minutes until fully mixed, and add 10% polyethylene glycol Glycol solution, making soft material for 1 minute, granulating through a swinging granulator (20 mesh stainless steel sieve);

[0058] S3. Dry the wet granules in a boiling dryer, set the air inlet temperature to 60°C, dry until the material temperature reaches 40°C, stop heating, discharge, and granulate with a 18-mesh sieve;

[0059] S4, mixing the sized clopidogrel hydrogen sulfate particles with hydrogenated castor oil with a particle size of 90 microns, and compressing the mixed product into tablets;

[0060] S5. Coating to obtain clopidogr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com