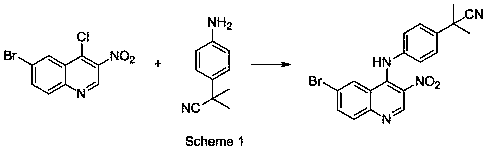

A kind of preparation method of antineoplastic drug nvp-bez235 intermediate

A technology of solid acid catalyst and attapulgite, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problem of low yield of waste acid, achieve simple preparation method, facilitate operation, and improve yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

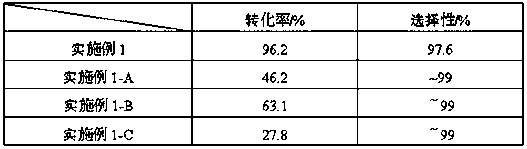

Examples

Embodiment 1

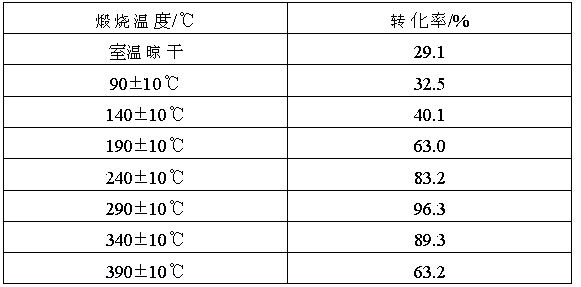

[0043] Preparation of novel tin-modified ZrO 2 / Attapulgite solid acid catalyst, comprising the following steps:

[0044] 1) Pre-treatment process of attapulgite: crush 100g of attapulgite into particles with a particle size of 100 mesh, and then place it in 500ml of hydrochloric acid in tetrahydrofuran solution (hydrochloric acid concentration is 2mol / L), sonicate for 24h, filter, and dry at 100°C , Grinding and crushing until the particle size is 200-300 mesh to obtain attapulgite powder;

[0045] 2) Co-deposition process: put 10g of attapulgite powder in n-propanol, then add 0.89g of 70%wt n-propoxide zirconium (IV) n-propanol solution and 0.20 g of SnCl 4 ·5H 2 O Stir and mix evenly, heat up to 60-70°C and stir vigorously at 1000rpm for 30 minutes; slowly add 1mol / L ammonia solution dropwise to adjust the pH of the solution to 10.0, then keep warm and stir for 24 hours; cool down to room temperature, suction filter, wash with water Until the filtrate becomes neutral, t...

Embodiment 1-A

[0048] Compared with Example 1, the difference is that SnCl is not added in step 2) 4 ·5H 2 O, all the other are completely consistent with embodiment 1.

Embodiment 1-B

[0050] Compared with Example 1, the difference is that in step 3), 30 ml of acetic acid is used instead of 30 ml of acetic acid / concentrated sulfuric acid mixed acid (the weight ratio of acetic acid to concentrated sulfuric acid in the mixed acid is 1:2), and the rest are exactly the same as in Example 1. unanimous.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com