Gas-based trace chemistry tracer and method for using gas-based trace chemistry tracer to measure gas production contribution amount of various sections of gas well

A chemical tracer and tracer technology, which is applied in the field of gas-based trace chemical tracers to measure the contribution of gas production in each section of a gas well by using chemical tracers, can solve the problems of difficult determination of contribution, and achieve biological stability Good chemical stability, good data reproducibility, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: from 2XX wells

[0053] 1. Formulation of tracer dosage

[0054] The design of tracer dosage needs to be comprehensively formulated in combination with conditions such as pressure, formation lithology conditions and single-stage productivity. The dosage calculation formula is:

[0055] M=100*K p *T*3.14*r 2

[0056] In the formula:

[0057] M—the amount of tracer, kg;

[0058] K p —— formation porosity, %;

[0059] T——The minimum tracer concentration of the tracer (ppb);

[0060] R——maximum production capacity radius, m.

[0061] 2. Pump injection of tracer

[0062] For tracer injection, the fracturing design plan must be provided first, and then the operator will design the tracer injection according to the fracturing plan, and design the tracer injection process according to the fracturing pumping procedure.

[0063] 3. On-site injection of tracer

[0064] Well 2XX began to inject the first stage of tracer with the fracturing fluid on December 20...

Embodiment 2

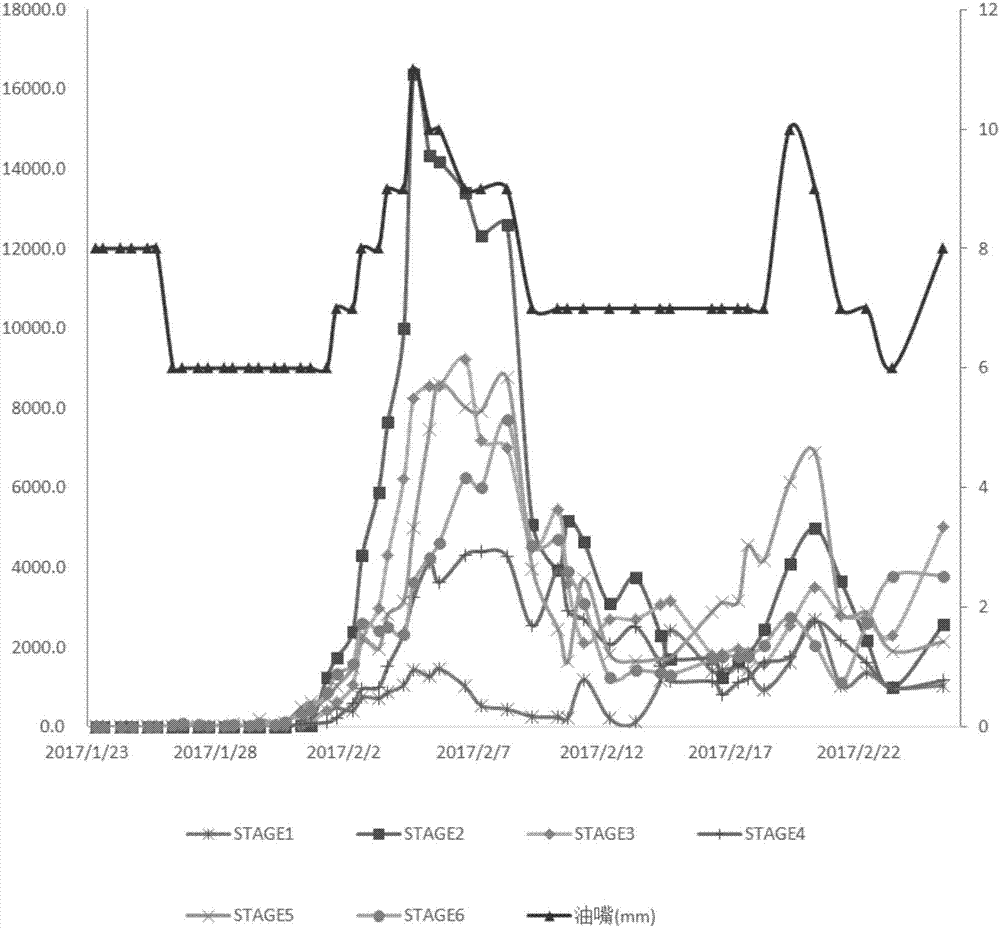

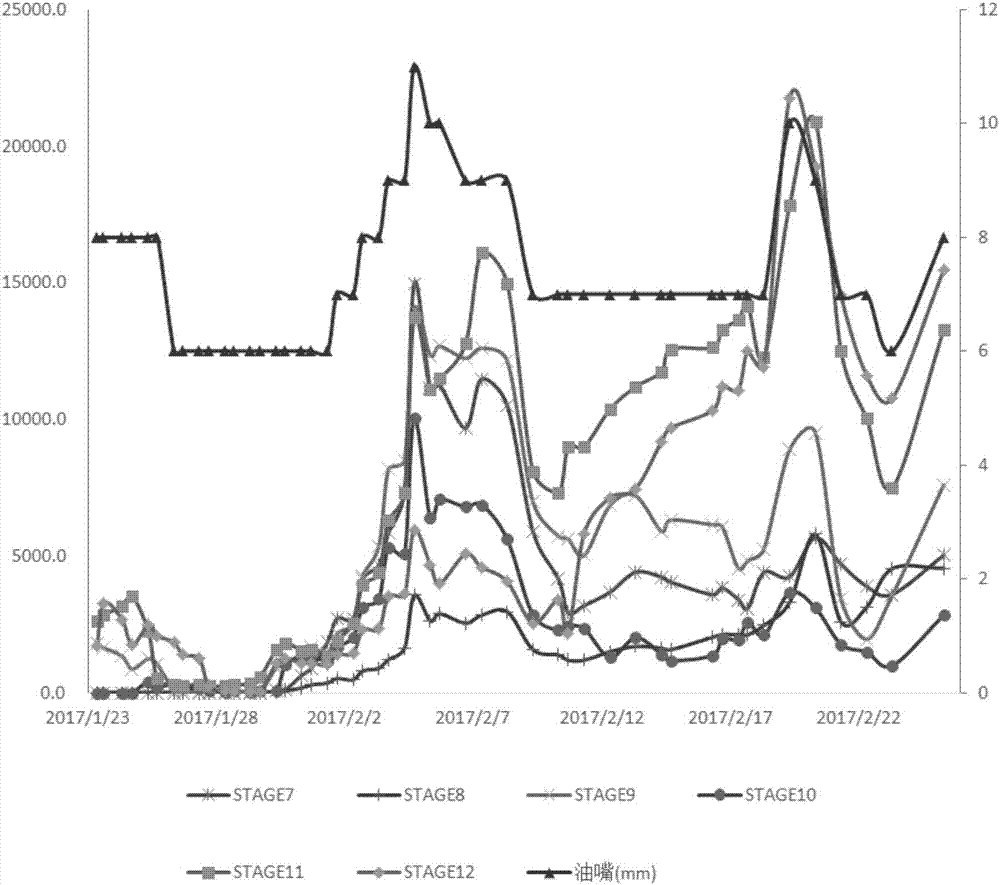

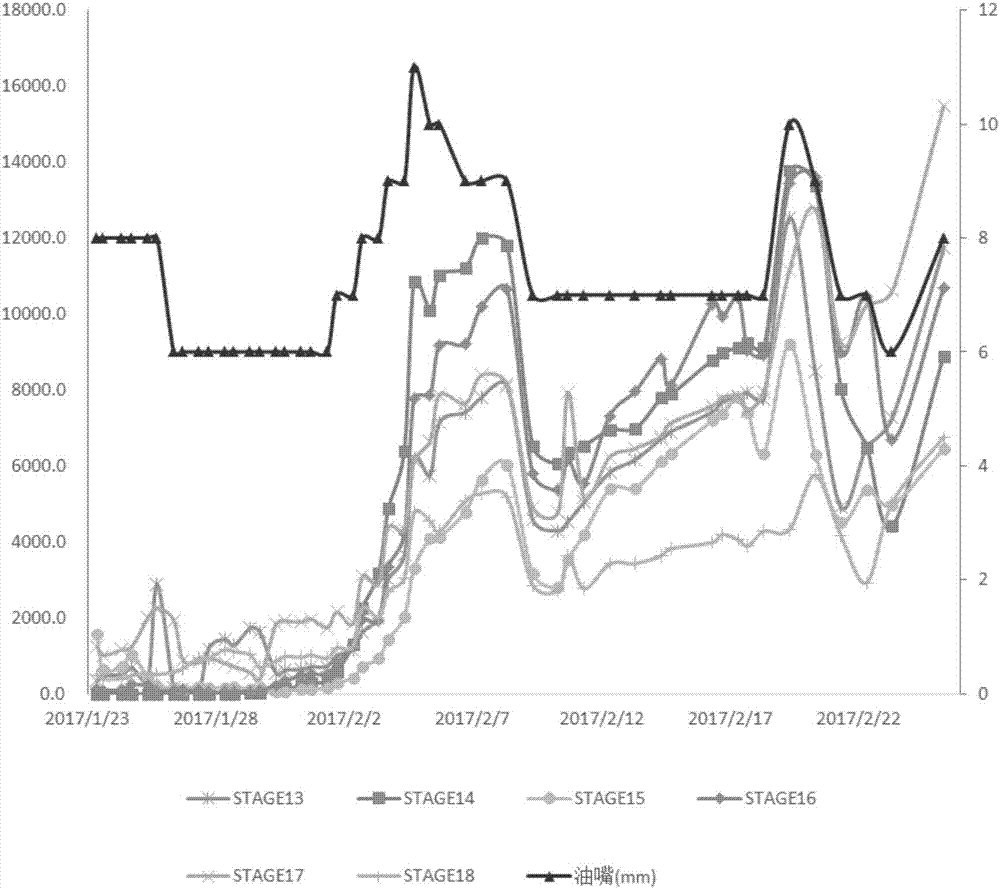

[0073] Example 2: Gao 001-XX well

[0074] 1. The tracer injection scheme is shown in Table 2-6

[0075] Table 2 The first stage tracer injection process

[0076]

[0077] Note: The gas agent is added from the liquid volume of 50 cubic meters, and the addition time is 10 minutes.

[0078] Table 3 The tracer injection process in the second stage

[0079]

[0080] Note: The gas agent is added from the liquid volume of 35 cubic meters, and the addition time is 10 minutes.

[0081] Table 4 The third stage tracer injection process

[0082]

[0083] Note: The gas agent is added from the liquid volume of 50 cubic meters, and the addition time is 10 minutes.

[0084] Table 5 Tracer injection process in the fourth stage

[0085]

[0086] Note: The gas agent is added from the liquid volume of 35 cubic meters, and the addition time is 10 minutes.

[0087] Table 6 Tracer injection process in the fifth section

[0088]

[0089]

[0090] Note: The gas agent is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com