Ultra-thin bonded NdFeB magnet used for computer CPU cooling fan and preparation method thereof

A cooling fan, NdFeB technology, applied in the direction of permanent magnet manufacturing, magnets, magnetic objects, etc., can solve the problems of poor temperature stability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

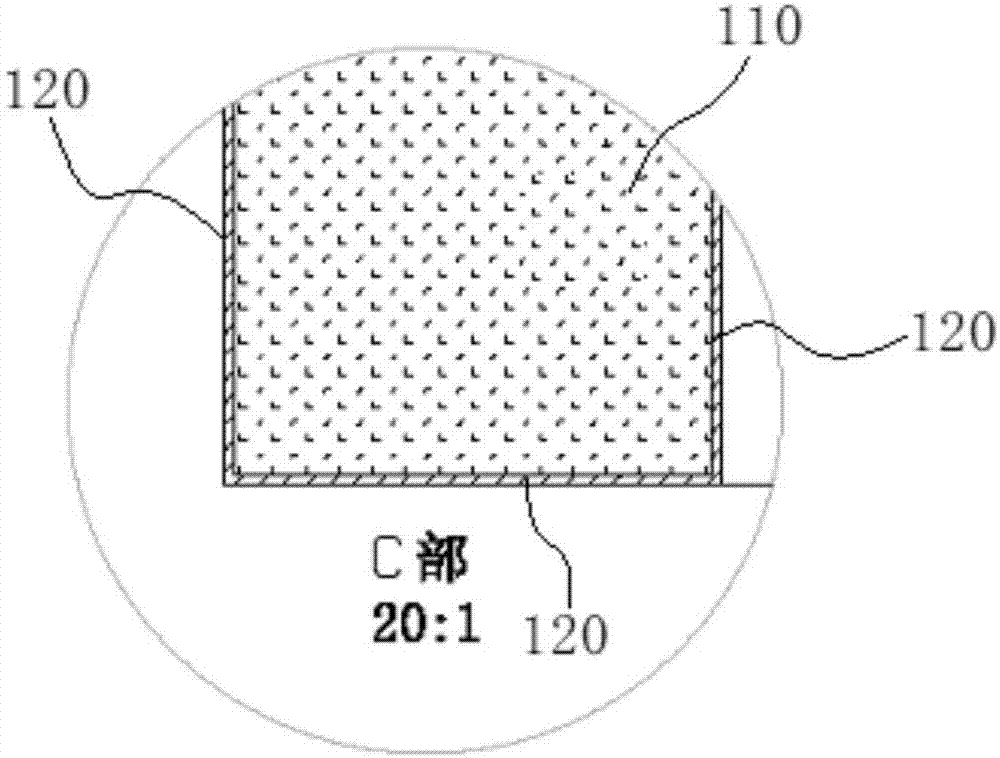

[0063] For the preparation of ultra-thin bonded NdFeB magnets, it is realized based on the following steps:

[0064] Step 1: Preparation of permanent magnetic powder, non-magnetic powder and composite binder powder mixture:

[0065] According to the weight percentage of mixing, 58-99.5% of permanent magnetic powder, 0-41.5% of non-magnetic powder, 0.5-42% of composite binder are uniformly mixed under normal temperature and pressure to make permanent magnetic powder and non-magnetic powder. Mixture powder of magnetic powder and composite binder;

[0066] Step 2: One-time molding of ultra-thin bonded NdFeB magnets:

[0067] The prepared mixed powder is subjected to one-time compression molding at room temperature and pressure of 2-20 tons / square centimeter; then cured at 80-250°C for 5-120 minutes, and the product is cured from the inside to the outside by infrared heating The curing method is first inside and then outside to shorten the liquid phase time, thus making ultra-th...

Embodiment 1

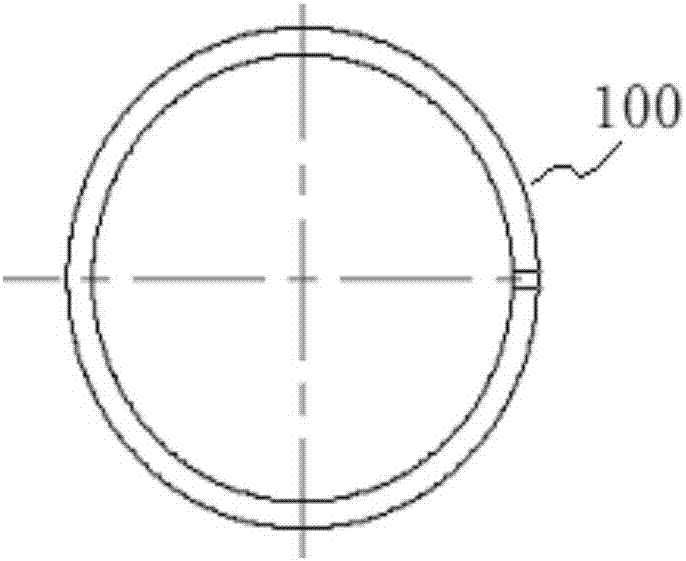

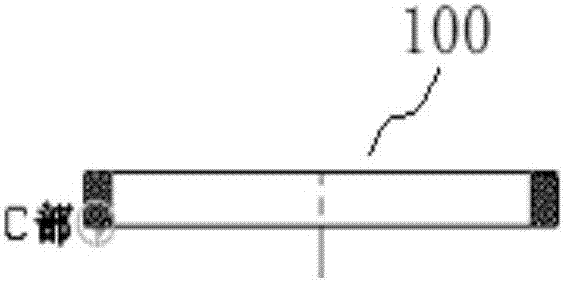

[0075] The ultra-thin bonded NdFeB magnet provided in this example is made of bonded NdFeB, ring-shaped, and its relevant dimensions:

[0076] The outer diameter of the ring magnet: 19mm;

[0077] The inner diameter of the ring magnet: 17mm;

[0078] The height dimension of the ring magnet: 2mm;

[0079] The roundness of the outer diameter of the ring magnet: less than 0.03mm;

[0080] Coaxiality of circular magnet: less than 0.03mm;

[0081] Roundness of the inner diameter of the ring magnet: less than 0.03mm.

[0082] And the magnetic properties of the ultra-thin bonded NdFeB magnet:

[0083] Maximum energy product (BH)max: 24kJ / m 3 ;

[0084] The number of magnetic poles of the magnet is 4.

[0085] For this ultra-thin bonded NdFeB magnet, it is prepared through the following steps:

[0086] Step 1: Mix permanent magnetic powder and composite binder Preparation: Mix 62% permanent magnetic powder, 2.5% composite binder, and 35.5% non-magnetic substances uniformly at ...

Embodiment 2

[0096] The ultra-thin bonded NdFeB magnet provided in this example is made of bonded NdFeB filled with 1% SmCo magnetic powder, ring-shaped, and its relevant dimensions:

[0097] The outer diameter of the ring magnet: 11.9mm;

[0098] The inner diameter of the ring magnet: 10.1mm;

[0099] The height dimension of the ring magnet: 1.2mm;

[0100] The roundness of the outer diameter of the ring magnet: less than 0.03mm;

[0101] Coaxiality of circular magnet: less than 0.03mm;

[0102] Roundness of the inner diameter of the ring magnet: less than 0.03mm.

[0103] And the magnetic properties of the ultra-thin bonded NdFeB magnet:

[0104] Maximum energy product (BH)max: 96kJ / m 3 ;

[0105] The number of magnetic poles of the magnet is 8.

[0106] For the ultra-thin bonded NdFeB magnet, the electrophoresis method is used for its preparation, the electrophoresis condition is 60° C. for 20 minutes, and the curing condition is 180° C. for 1 hour.

[0107] The ultra-thin bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com