A crimping structure with multi-level thyristors connected in series

A technology of thyristor and connection structure, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problem of not meeting the pressing force requirements of larger-sized thyristors, not completely limiting the degree of freedom of the radiator, and not being able to precisely control The size of the pressing force and other issues can achieve good heat dissipation effect and flow effect, ensure good contact, and the effect of simple pressure method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

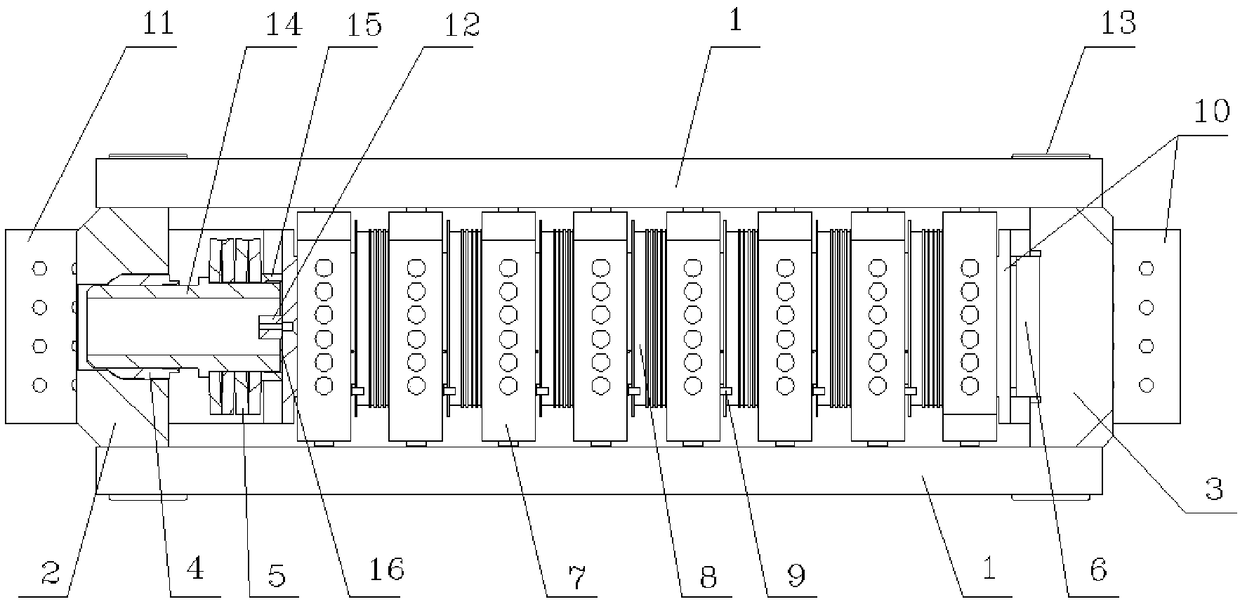

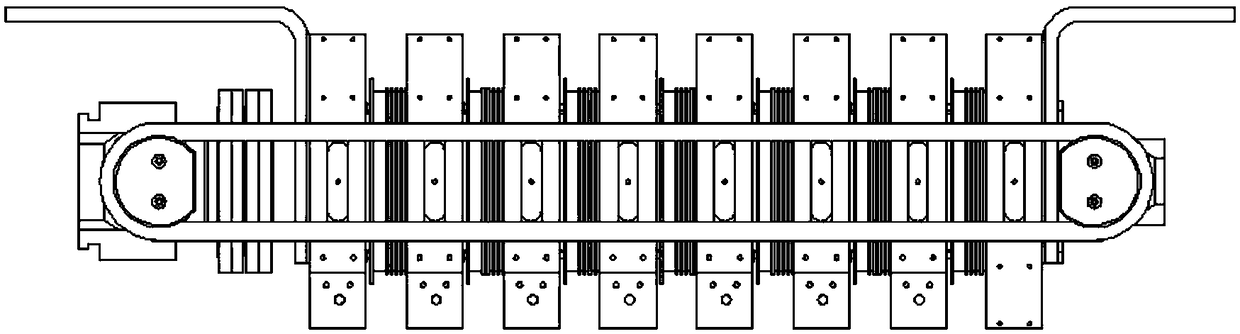

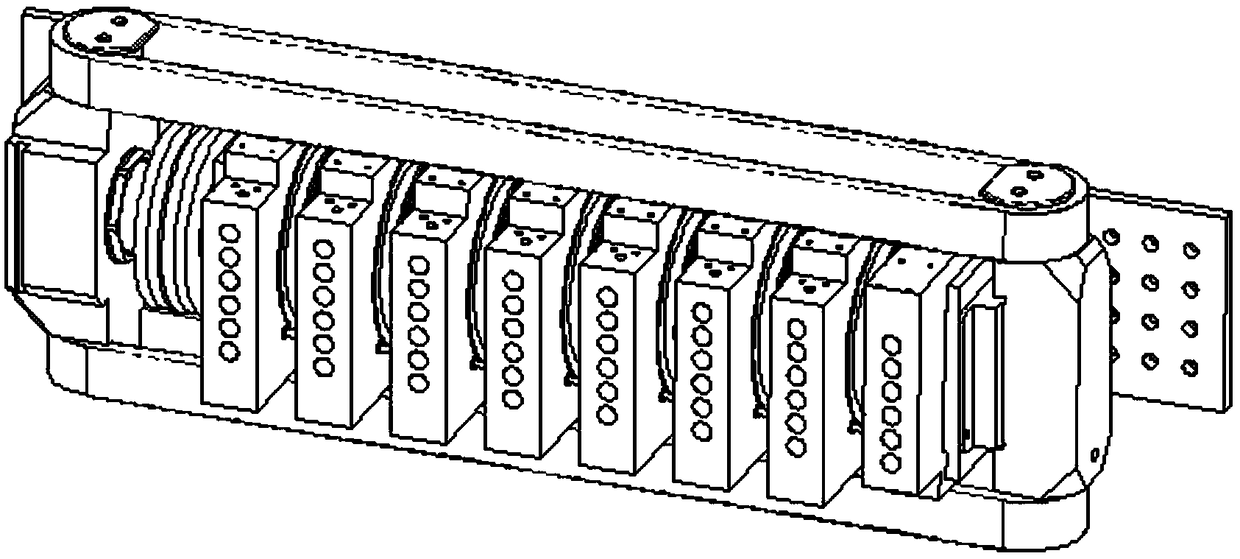

[0026] The multilevel thyristor crimping structure of the present invention, its front view is as follows figure 1 As shown, the top view is as figure 2 As shown, the 3D view is as image 3 as shown,

[0027] The two insulating pull rings 1 arranged up and down and the left yoke 2 and right yoke 3 connected to the two insulating pull rings 1 form the external frame of the crimping structure. The multi-stage thyristor crimping structure consists of crimping thyristors 8 and radiators 7 Phases are connected in series to form the entire silicon stack unit. The two ends of the silicon stack unit are respectively connected to the left output bus bar 11 and the right output bus bar 10, and then installed between the left yoke 2 and the right yoke 3 through the pressure unit arranged at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com