Supported catalyst capable of deeply degrading industrial dye waste water and preparation method thereof

A supported catalyst and dye wastewater technology, which is applied in textile industry wastewater treatment, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low repetition rate and reusability of reaction catalysts, low efficiency of pure ozone oxidation reaction, ozone Response to harsh pH conditions and other issues, to achieve good reusability, stable structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

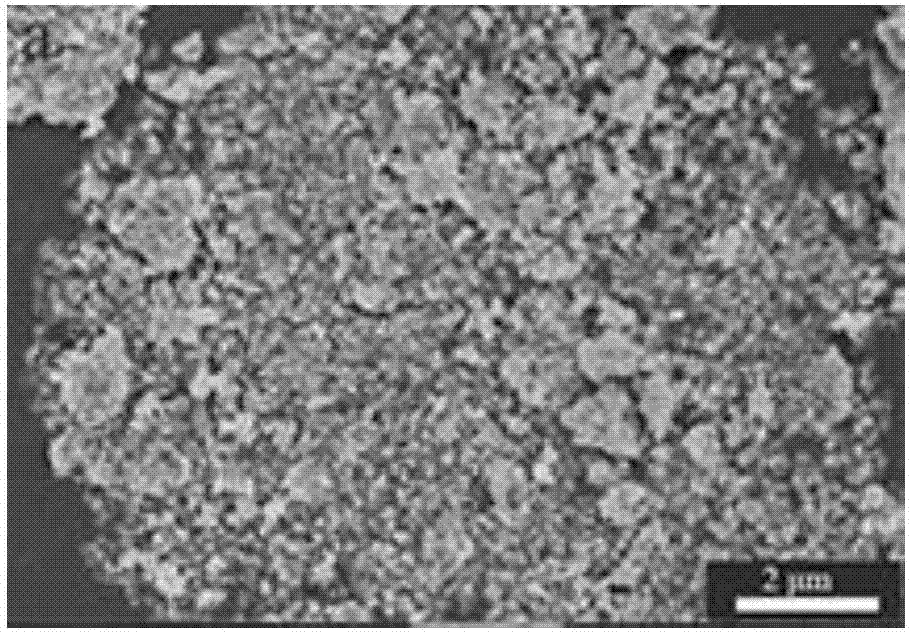

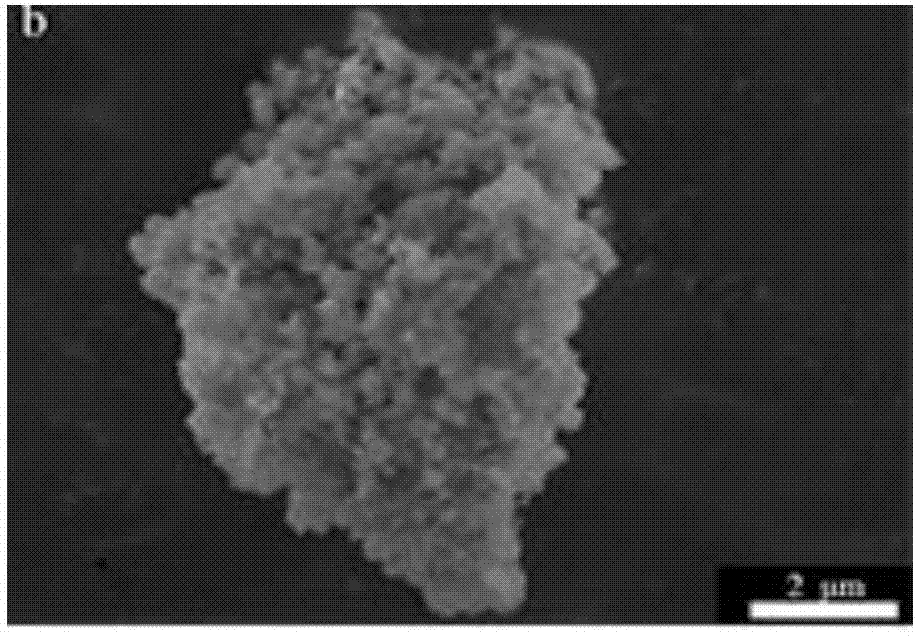

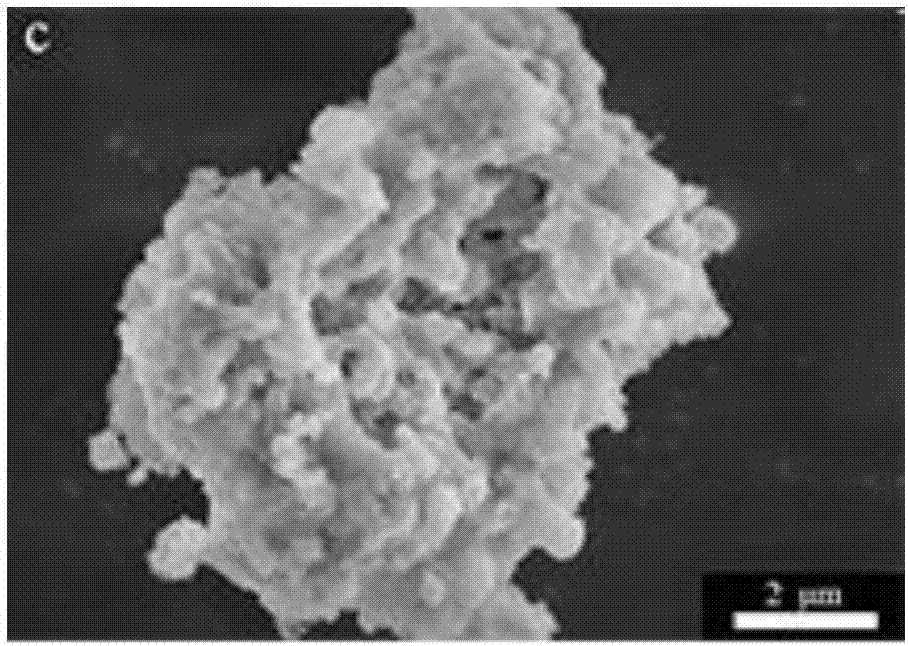

Image

Examples

preparation example Construction

[0040] The invention provides a supported catalyst for deeply degrading industrial dye wastewater and a preparation method thereof. The catalyst includes Fe and Mn double transition metal supported MCM-41 mesoporous molecular sieve catalyst, Fe supported MCM-41 mesoporous molecular sieve catalyst and Mn Loaded MCM-41 mesoporous molecular sieve catalyst, the specific preparation method steps are as follows:

[0041] The first step, impregnation pretreatment of carrier powder and loaded active components;

[0042] The molecular sieve powder was placed in an ethanol solvent for ultrasonic vibration to obtain solution A; the volume-to-mass ratio of ethanol and molecular sieve was 20mL: 1g.

[0043] The Fe source and Mn source precursor Fe(NO 3 ) 3 9H 2 O and Mn(CH 3 CO 2 ) 2 ·H 2 O was dissolved in high-purity water simultaneously or separately in proportion, and ultrasonically oscillated to obtain solution B. Among them, m(Fe):m(MCM-41)=10:100, m(Mn):m(MCM-41)=5:100. M(F...

Embodiment 1

[0052] Example 1: Preparation of Fe-Mn / MCM-41 catalyst:

[0053] The first step is the impregnation pretreatment process of carrier powder and loaded active components;

[0054] Weigh 1.0 g of molecular sieves into a 50 mL beaker A, add 20 mL of pure ethanol into beaker A, stir with a glass rod to distribute the molecular sieves evenly and perform ultrasonic vibration for 5 minutes to obtain solution A. Simultaneously weigh Fe(NO 3 ) 3 9H 2 O powder medicine 482.68mg and Mn(CH 3 COO) 2 ·H 2 Place 222.81 mg of powder medicine in a 50ml beaker B, add 20mL of high-purity water to beaker B, stir the powder medicine with a glass rod to make it fully dissolve and ultrasonically vibrate for 5 minutes to obtain solution B. Mix solution A and solution B in 100ml beaker C and carry out magnetic stirring for 24 hours, so that Fe and Mn ions are fully adsorbed on the surface of MCM-41 mesoporous molecular sieve, and mixed solution C is obtained. Select 1.5mL concentrated ammonia ...

Embodiment 2

[0058] Example 2: Preparation of Fe / MCM-41 catalyst:

[0059] The first step is the impregnation pretreatment process of carrier powder and loaded active components;

[0060] Weigh 1.0g of MCM-41 mesoporous molecular sieves into a 50mL beaker, add 20mL of pure ethanol to the beaker, stir with a glass rod to make the molecular sieves evenly distributed and perform ultrasonic vibration for 5min to obtain solution A. Weigh Fe(NO 3 ) 3 9H 2 Place 482.68mg of powder medicine in a 50mL beaker, add 20mL of high-purity water into the beaker, stir the powder medicine with a glass rod to fully dissolve and ultrasonically vibrate for 5min to obtain solution B. Mix solution A and solution B in a 100ml beaker and perform magnetic stirring for 24 hours, so that Fe ions are fully adsorbed on the surface of MCM-41 mesoporous molecular sieves, and mixed solution C is obtained. Prepare an ammonia solution D with a volume ratio of 1.5mL concentrated ammonia water: 8.5mL high-purity water. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com