Solar energy soft-porcelain decorative material and preparation method of same

A decorative material and solar energy technology, applied in the field of architectural decorative materials, can solve the problems of complicated production process, complex structure, hard building material, etc., and achieve the effect of improving light energy utilization rate, improving light conversion rate, and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

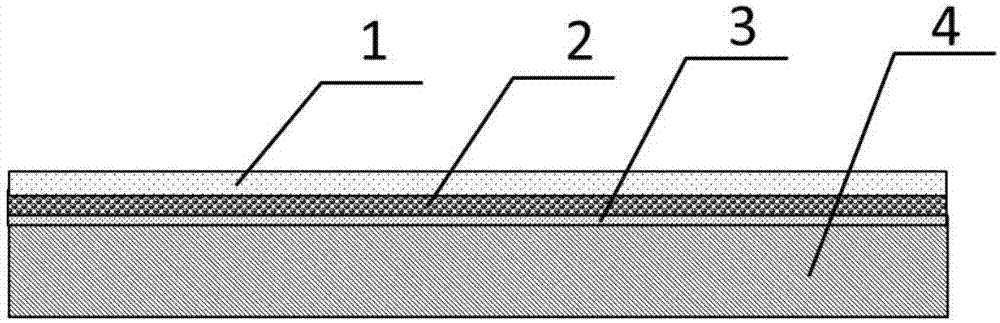

[0030] A solar soft porcelain decorative material is characterized in that it includes a base layer and a solar energy conversion layer, the base layer is a soft porcelain material, the solar energy conversion layer is a flexible solar cell module, and a layer of titanium dioxide reflective layer is arranged between the base layer and the solar energy conversion layer. A transparent protective layer is arranged on the conversion layer. The preparation method of the solar soft porcelain decorative material comprises the following steps, and each reagent is measured by weight.

[0031] Step (1) Prepare base layer powder: Take 10 parts of cement, 2 parts of coupling agent, and 1 part of inorganic pigment, add them into a kneader and mix evenly to obtain surface layer powder.

[0032] Step (2) Prepare the base layer mixture: add the surface layer powder obtained in step (1) to 20 parts of silicon-acrylic emulsion, add 10 parts of water, and stir to obtain the base layer mixture; ...

Embodiment 2

[0039] A solar soft porcelain decorative material is characterized in that it includes a base layer and a solar energy conversion layer, the base layer is a soft porcelain material, the solar energy conversion layer is a flexible solar cell module, and a layer of titanium dioxide reflective layer is arranged between the base layer and the solar energy conversion layer. A transparent protective layer is arranged on the conversion layer. The preparation method of the solar soft porcelain decorative material comprises the following steps, and each reagent is measured by weight.

[0040] Step (1) Prepare base layer powder: Take 10 parts of cement, 2 parts of coupling agent, and 1 part of inorganic pigment, add them into a kneader and mix evenly to obtain surface layer powder.

[0041] Step (2) Prepare the base layer mixture: add the surface layer powder obtained in step (1) to 20 parts of silicon-acrylic emulsion, add 10 parts of water, and stir to obtain the base layer mixture; ...

Embodiment 3

[0048] A solar soft porcelain decorative material is characterized in that it includes a base layer and a solar energy conversion layer, the base layer is a soft porcelain material, the solar energy conversion layer is a flexible solar cell module, and a layer of titanium dioxide reflective layer is arranged between the base layer and the solar energy conversion layer. A transparent protective layer is arranged on the conversion layer. The preparation method of the solar soft porcelain decorative material comprises the following steps, and each reagent is measured by weight.

[0049] Step (1) Prepare base layer powder: Take 10 parts of cement, 2 parts of coupling agent, and 1 part of inorganic pigment, add them into a kneader and mix evenly to obtain surface layer powder.

[0050] Step (2) Prepare the base layer mixture: add the surface layer powder obtained in step (1) to 20 parts of silicon-acrylic emulsion, add 10 parts of water, and stir to obtain the base layer mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com