Ultrasonic sound assistant method for simulated digestion of casein active peptides and health food applications

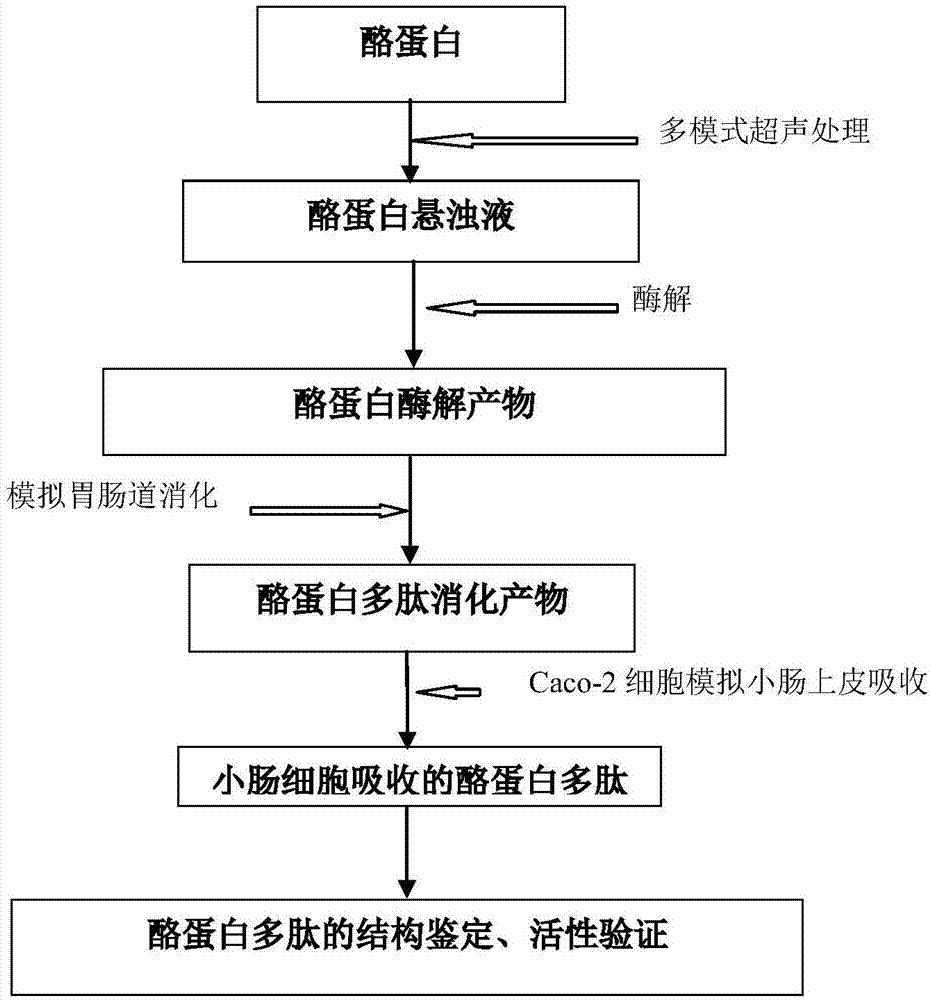

A casein and protease technology, which is applied in the fields of intensive processing of dairy products and functional food preparation, can solve the problems of inability to absorb peptides, ignoring the digestion and absorption of gastrointestinal tract, and ignoring the influence of selective absorption of small intestinal epithelial cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Ultrasonic treatment of casein: Weigh casein quantitatively, dissolve in phosphate buffer solution with pH=7.8, and the concentration of casein is 1g / 100mL. Single frequency (40kHz) sonication. The ultrasonic treatment time is 30min, the intermittent ratio is 10s / 3s, and the temperature is 25°C.

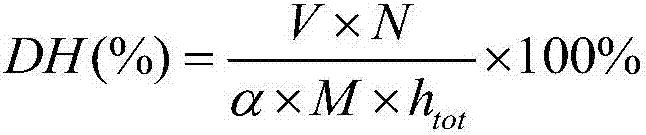

[0056] Preparation of casein enzymatic hydrolysis solution: adjust the pH of the above protein solution to 8, add alkaline protease, the ratio of enzyme to substrate is 1:20 (w / w), mix evenly, enzymolysis temperature is 50°C, and enzymolysis time is 2h. After the enzymolysis, adjust the pH of the mixture to 7.0, and inactivate the enzyme in a boiling water bath for 10 minutes, centrifuge to obtain a supernatant, desalt, concentrate, and freeze-dry to powder. The degree of hydrolysis of casein, the conversion rate of protein, and the ACE inhibitory activity of its hydrolyzate were measured.

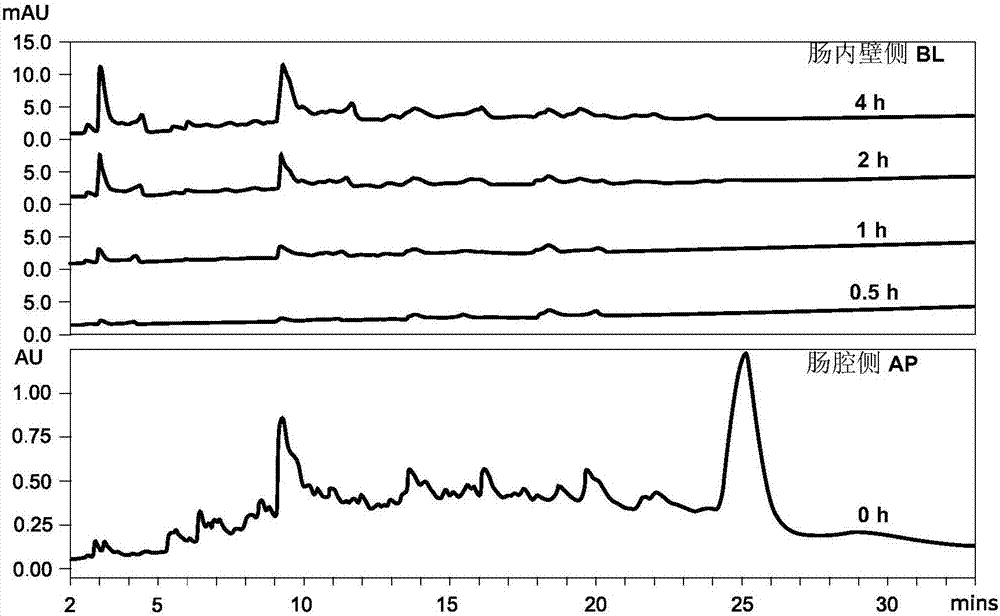

[0057] Simulated gastrointestinal digestion: Prepare artificial gastric juice accord...

Embodiment 2

[0060] Ultrasonic treatment of casein: Weigh casein quantitatively, dissolve in phosphate buffer solution with pH=7.8, and the concentration of casein is 2g / 100mL. Dual frequency (20 / 40kHz) ultrasonic processing. The ultrasonic treatment time is 20min, the intermittent ratio is 10s / 3s, and the temperature is 30°C.

[0061] Preparation of casein hydrolyzate: adjust the pH of the above protein solution to 7.5, add neutral protease, the ratio of enzyme to substrate is 1:30 (w / w), mix evenly, enzymolysis temperature is 55°C, and enzymolysis time is 4h. After enzymolysis, adjust the pH of the mixture to 7.0, inactivate the enzyme in a boiling water bath for 10 minutes, centrifuge to obtain the supernatant, desalt, concentrate, and freeze-dry to powder. The degree of hydrolysis of casein, the conversion rate of protein, and the ACE inhibitory activity of its hydrolyzate were measured.

[0062] Simulated gastrointestinal digestion: Prepare artificial gastric juice according to the ...

Embodiment 3

[0065]Ultrasonic treatment of casein: Weigh casein quantitatively, dissolve in phosphate buffer solution with pH=7.8, and the concentration of casein is 5g / 100mL. Tri-frequency (20 / 40 / 60kHz) sonication. The ultrasonic treatment time is 10min, the intermittent ratio is 10s / 3s, and the temperature is 40°C.

[0066] Preparation of casein hydrolyzate: adjust the pH of the above protein solution to 8, add papain, the ratio of enzyme to substrate is 1:50 (w / w), mix evenly, enzymolysis temperature is 70°C, and enzymolysis time is 2h. After enzymolysis, the pH of the mixture was adjusted to 7.0, and the enzyme was inactivated in a boiling water bath for 10 minutes. The supernatant was obtained by centrifugation, desalted, concentrated, and lyophilized into powder. The degree of hydrolysis, protein conversion rate, and ACE inhibitory activity were measured.

[0067] Simulated gastrointestinal digestion: Prepare artificial gastric juice according to the United States Pharmacopoeia (USP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com