Methods for preparing graphene dispersant and graphene/raw paint composite anti-corrosive coating

A technology of graphene dispersant and graphene dispersion liquid, which is applied in the direction of anti-corrosion coatings, lignin coatings, natural resin coatings, etc., and can solve the problems of affecting the application effect of graphene, short anti-sedimentation time, poor graphene dispersion effect, etc. , to achieve the effect of improving anti-settling time, excellent anti-corrosion performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

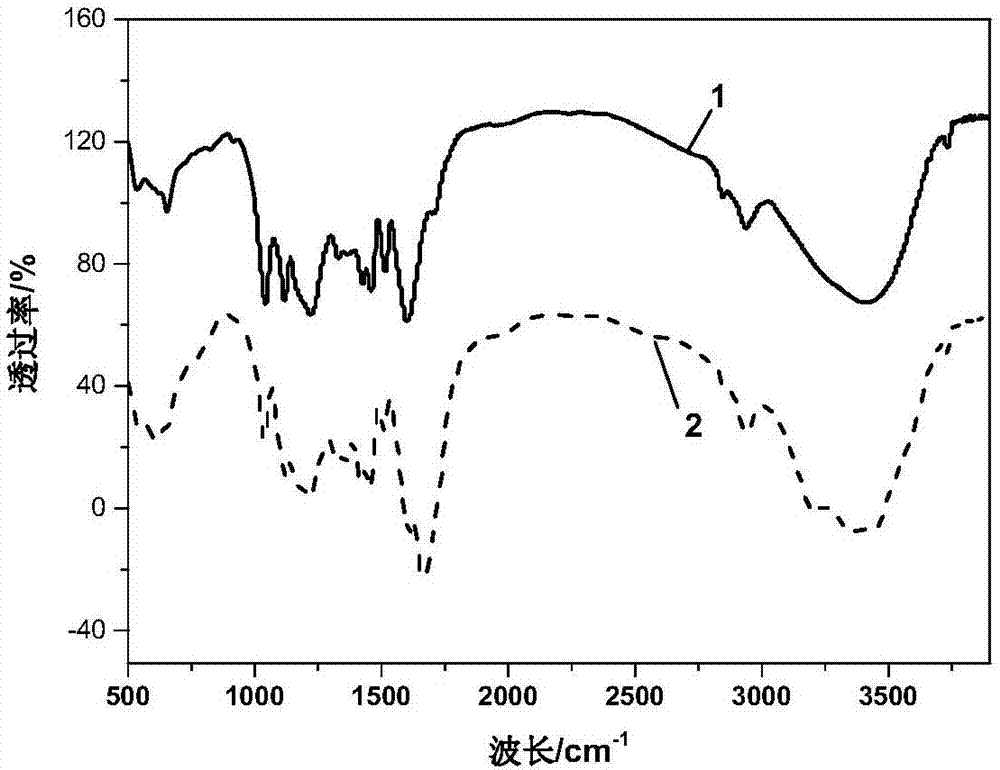

[0019] A preparation method of graphene dispersant, comprising the following steps:

[0020] S10. Take sodium lignosulfonate, ammonium persulfate and deionized water, add them into the reaction vessel and stir to fully dissolve the sodium lignosulfonate;

[0021] S20, add trans-1,2,3-propenetricarboxylic acid and acrylamide to react, after the reaction is complete, cool the reaction solution to room temperature;

[0022] S30. Add an organic solvent dropwise to the reaction solution to precipitate a solid, filter to obtain a crude product, purify and dry the obtained crude product to obtain a graphene dispersant.

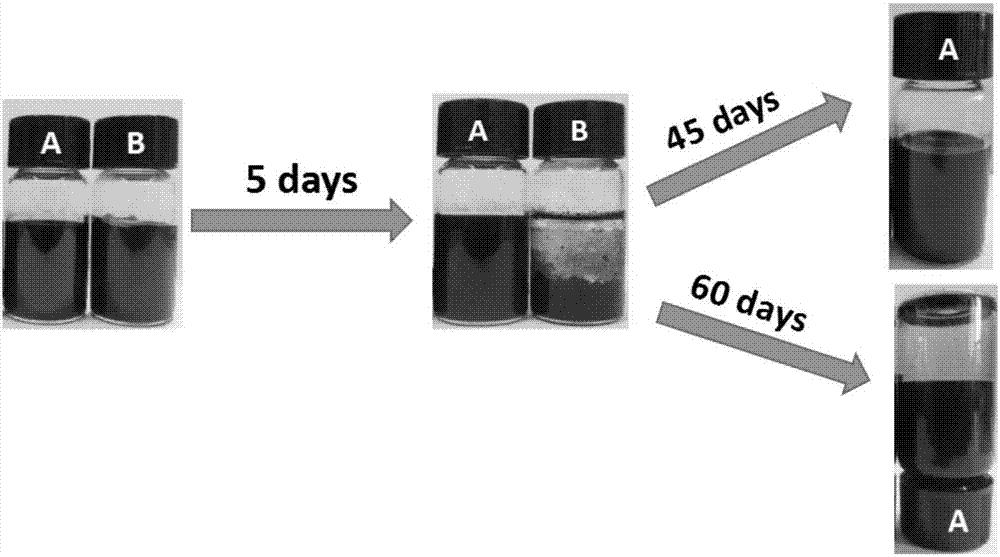

[0023] It can be seen from the above description that the beneficial effects of the present invention are: 1) The manufacturing cost is low. A large amount of by-product sodium lignosulfonate produced in the paper industry is used as a raw material to chemically modify modified lignin as a dispersion stabilizer for graphene, and the manufacturing cost is low; 2) the...

Embodiment 1

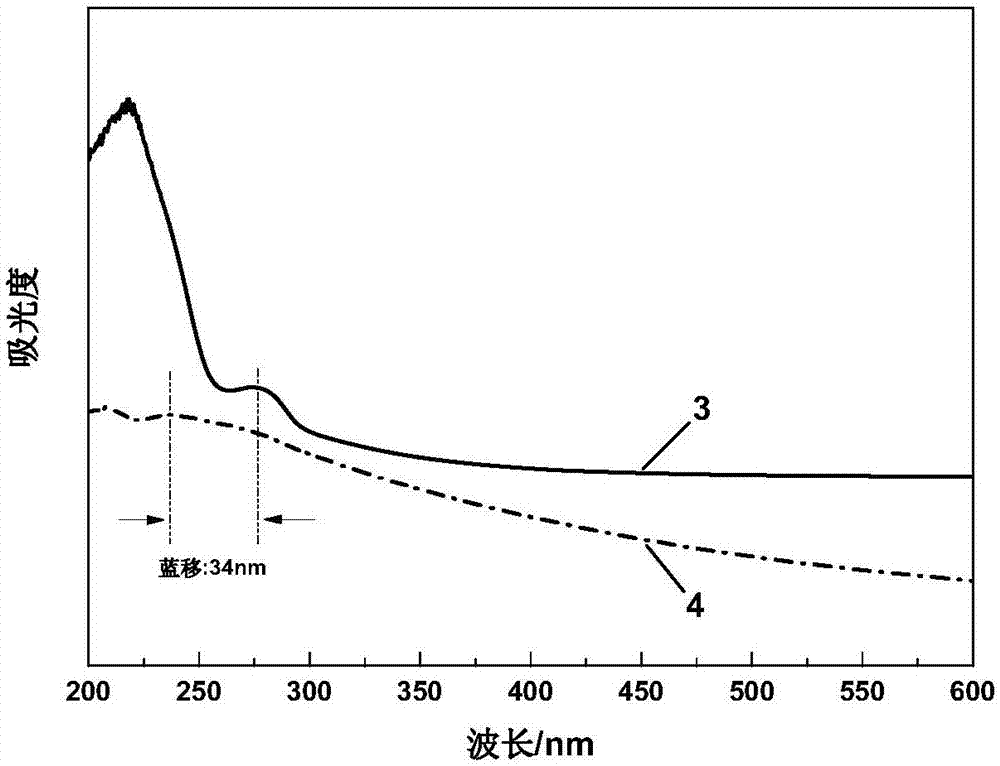

[0064] Weigh 1.00g of sodium lignosulfonic acid sodium salt (LS for short), 0.05g of ammonium persulfate and 20.00g of deionized water, add them into a 250ml three-necked flask, and stir at room temperature for 20min to fully dissolve LS; Then add 5.00g trans-1,2,3-propenetricarboxylic acid and 5.00g acrylamide, in N 2 Under atmosphere, react at 75°C for 5h. The reaction was cooled to room temperature, and the reaction liquid was added dropwise into 250ml of isopropanol to precipitate a solid precipitate, and the crude product was obtained by filtration, which was subjected to Soxhlet extraction with acetone for 10 hours, and the obtained product was placed in a vacuum oven at 30°C to dry Dry 18h in the oven to obtain the graphene dispersant.

[0065] Weigh 0.60g of the above-mentioned graphene dispersant, add 100ml of deionized water, and after ultrasonication at room temperature for 10min, adjust the pH value of the solution to 9, then add 0.60g of graphene, continue ultras...

Embodiment 2

[0068] Weigh 1.00g of sodium lignosulfonate LS, 0.03g of ammonium persulfate and 20.00g of deionized water, add them into a 250ml three-neck flask, stir at room temperature for 20min to fully dissolve LS; then add 4.00g of trans-1 , 2,3-propenetricarboxylic acid and 4.00g acryloyl ammonium, in N 2 Under atmosphere, react at 80°C for 4h. The reaction was cooled to room temperature, and the reaction liquid was added dropwise into 250ml of isopropanol to precipitate a solid precipitate, and the crude product was obtained by filtration, and the obtained crude product was subjected to Soxhlet extraction with acetone solution for 10 h, and the obtained product was placed in a vacuum at 35°C Dry 15h in drying oven to obtain graphene dispersant.

[0069] Weigh 0.60g of the above-mentioned graphene dispersant, add 100ml of deionized water, and after ultrasonication at room temperature for 10min, adjust the pH value of the solution to 8, then add 0.80g of graphene, continue ultrasonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com