Aqueous anti-rust paint with REPVDC aqueous resin emulsion and preparation method thereof

A technology of water-based anti-rust paint and water-based resin, which is applied in the field of anti-rust paint, can solve the problems of water-based resin elimination, etc., and achieve the effects of excellent anti-rust performance, excellent storage stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

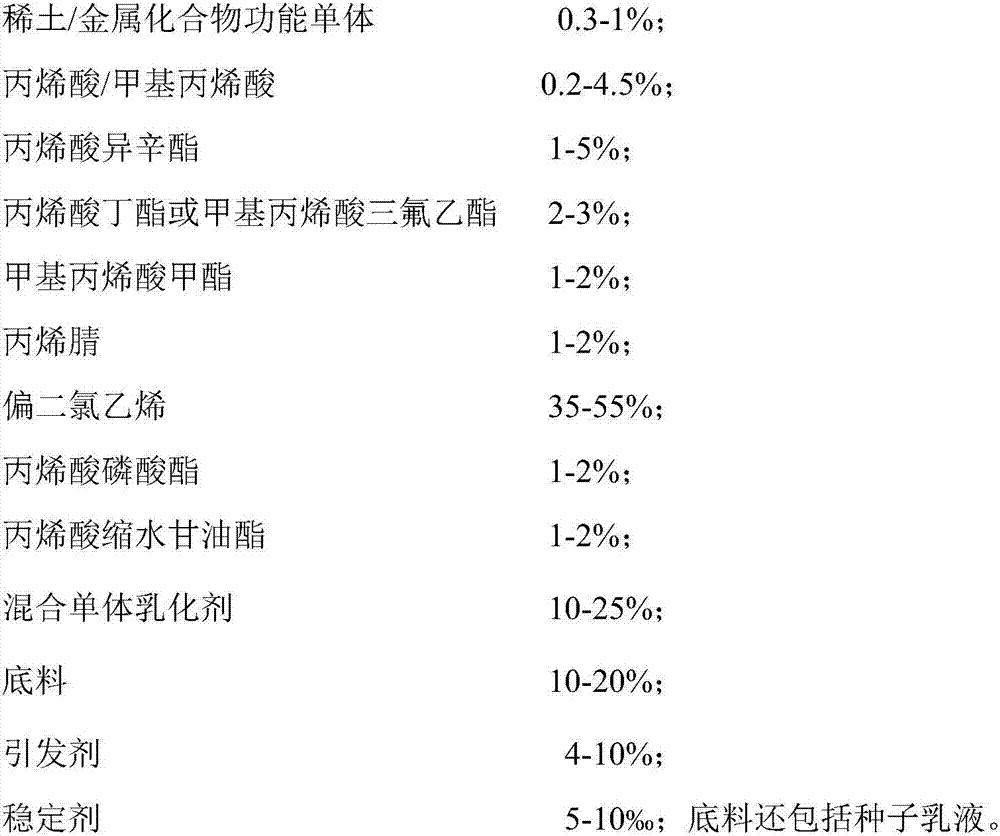

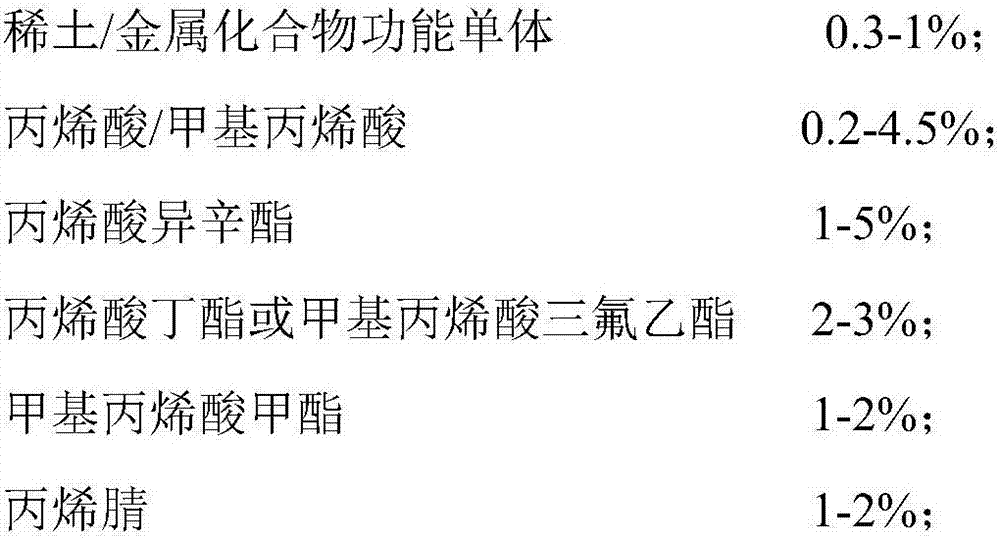

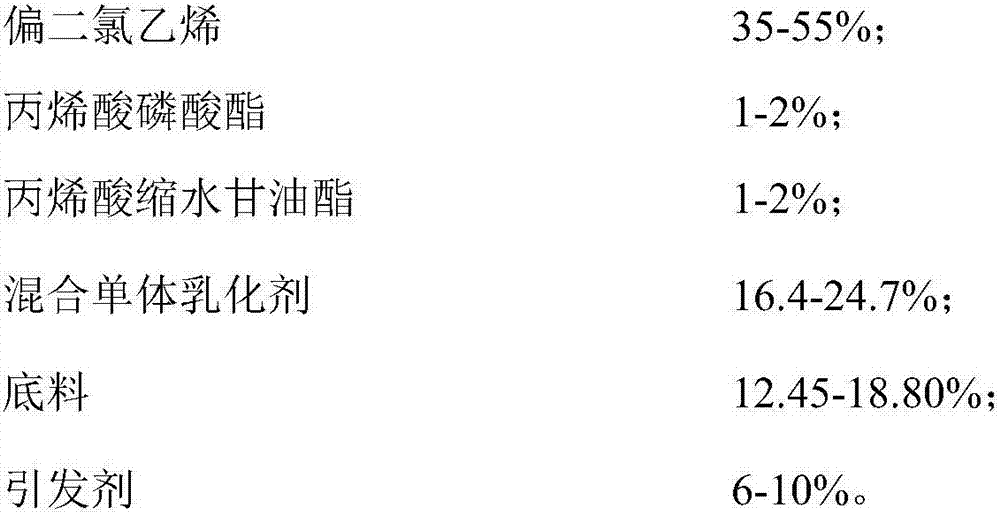

[0091] Antirust Primer Formula

[0092] sand abrasive formula one

[0093]

[0094] sand abrasive recipe two

[0095]

[0096]

[0097] Sand abrasive recipe three

[0098]

[0099] Base recipe one:

[0100]

[0101] Base recipe two:

[0102]

[0103]

[0104] Base formula three:

[0105]

Embodiment 2

[0106] Embodiment 2 Anti-rust intermediate paint formula

[0107] Sand abrasive formula one:

[0108]

[0109] Sand abrasive formula two:

[0110]

[0111]

[0112] Sand abrasive formula three:

[0113]

[0114] Base recipe one:

[0115]

[0116] Base recipe two:

[0117]

[0118]

[0119] Base formula three:

[0120]

Embodiment 3

[0122] Anti-rust surface paint formula

[0123] Sand abrasive formula one:

[0124]

[0125] Sand abrasive formula two:

[0126]

[0127] Sand abrasive formula three:

[0128]

[0129] Base recipe one:

[0130]

[0131]

[0132] Base recipe two:

[0133]

[0134] Base formula three:

[0135]

[0136] The REPVDC water-based steel structure antirust paint (coating) of embodiment 1~3 and other water-based steel structure antirust paints (coating) and performance comparison after film formation:

[0137]

[0138]

[0139] instruction manual:

[0140] 1. For the paint (paint) made of REPVDC water-based emulsion, the dry film thickness of one coat is 40-50um, while the dry film thickness of other water-based paints is 60-70um. Relatively speaking, the brushing area is larger than other water-based paints. The improvement is about 30%, and the anti-rust performance is better than other water-based paints. The cost performance is very high, and there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com